Liquid crystal display divice

A technology of liquid crystal display device and display area, applied in transistors, static indicators, optics, etc., can solve problems such as complex manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] In the liquid crystal display device of this embodiment, pixels are formed on a region surrounded by image signal lines extending vertically and arranged horizontally and scanning signal lines extending horizontally and arranged vertically, and a pixel electrode and a pixel electrode are arranged in each pixel. TFT for switching. Pixels including pixel electrodes and TFTs are arranged in a matrix on the display area. A drive circuit for controlling supply of an image signal to each pixel is provided on the periphery of the display area. In this embodiment, bottom-gate poly-Si TFTs are used for both the TFTs used in the pixel portion and the TFTs used in the driver circuit. Here, poly-Si TFT means using poly-Si as a semiconductor.

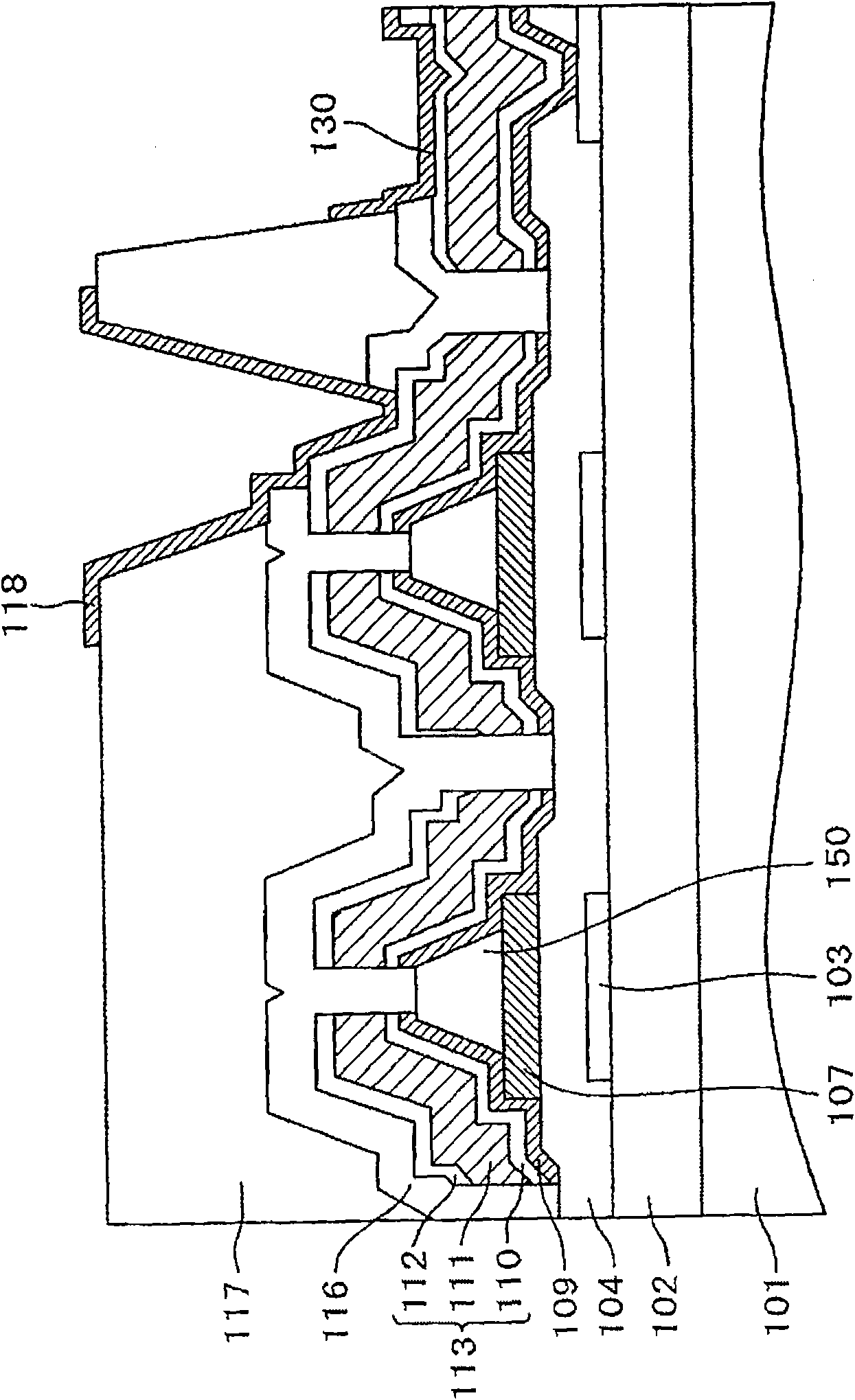

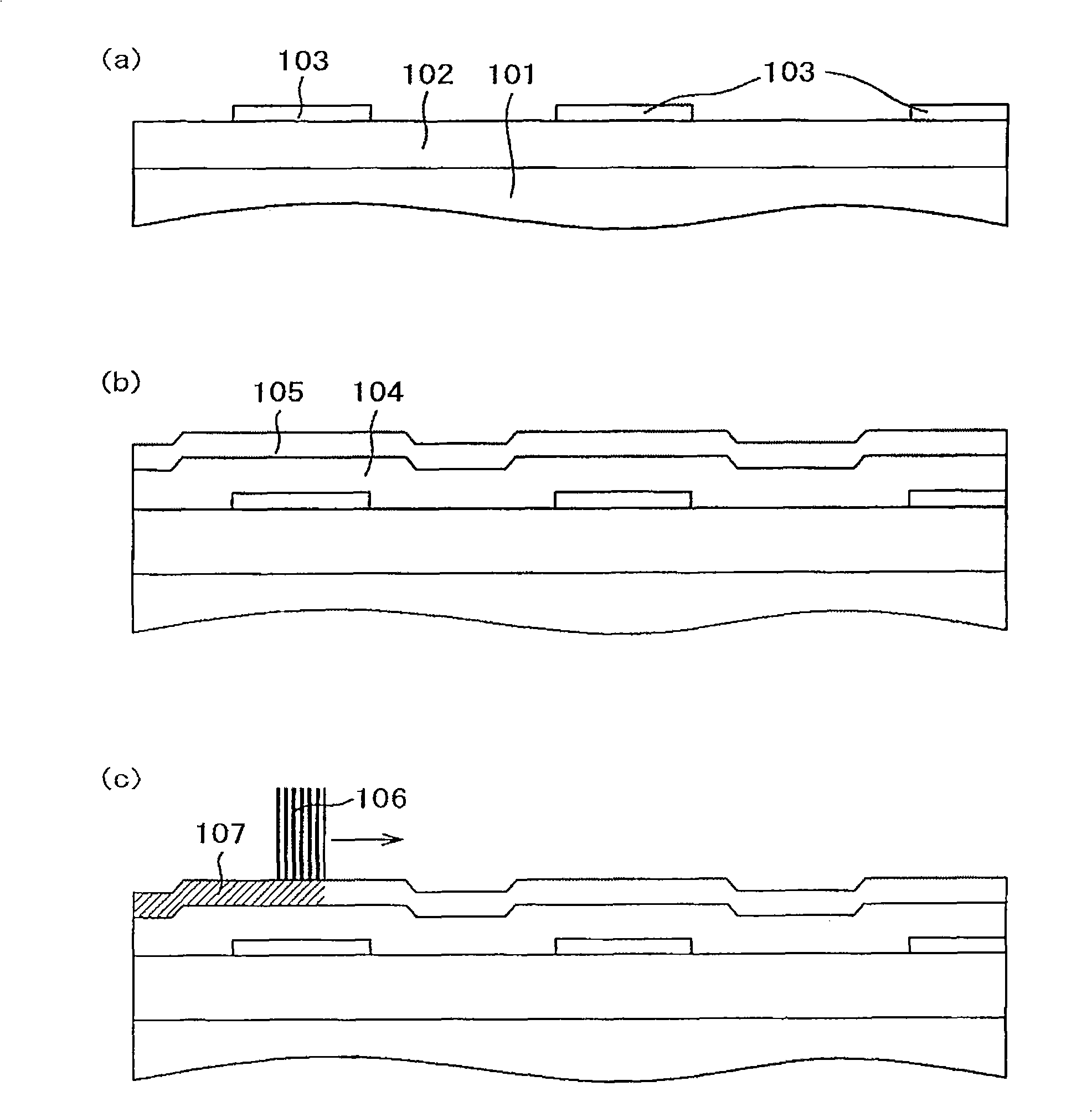

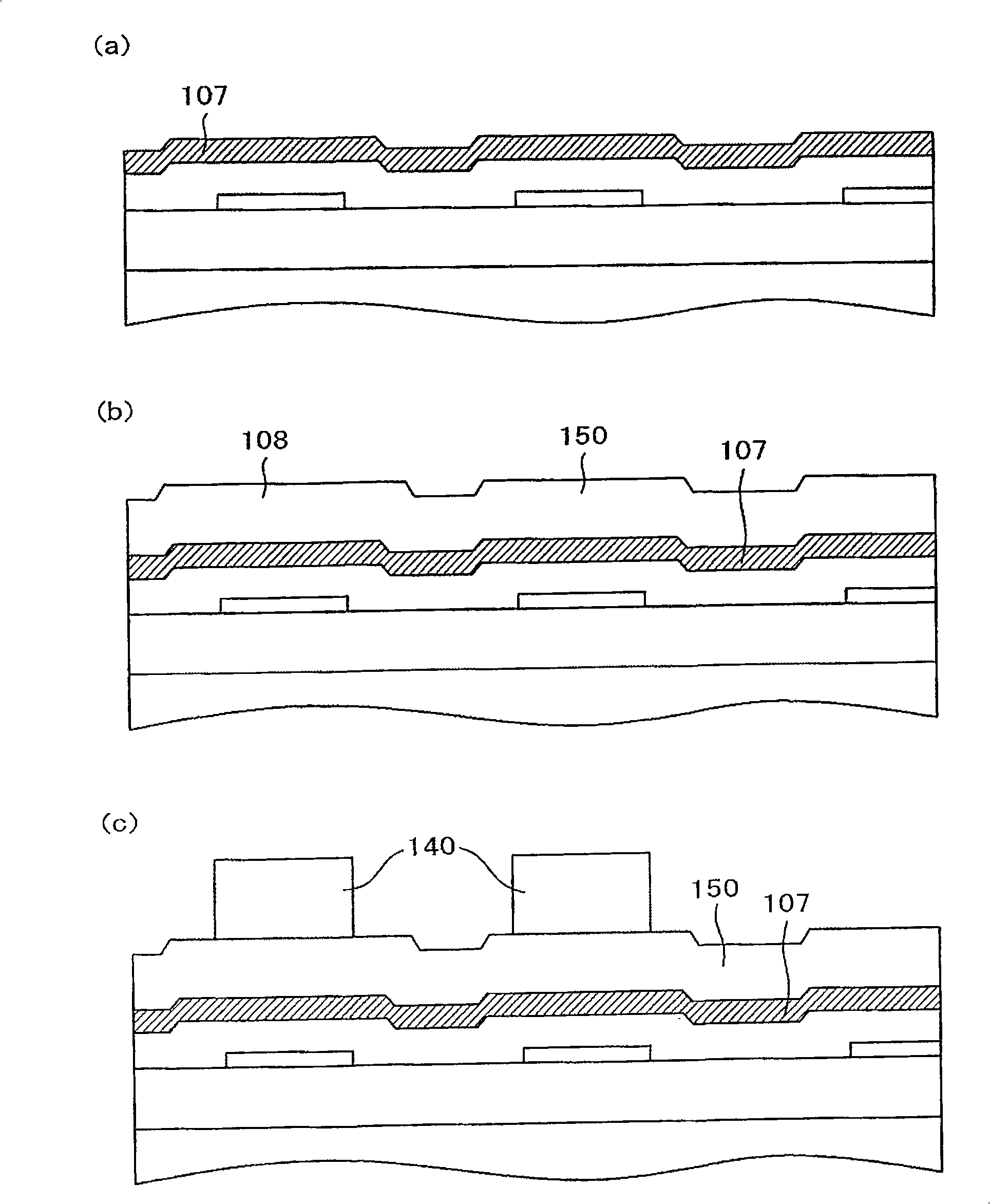

[0052] figure 1 is a schematic cross-sectional view showing the structure of the present invention. exist figure 1 In the figure, the TFT on the left is a TFT used in the driver circuit section. The TFT on the right is a TFT used in t...

Embodiment 2

[0072] In this embodiment, the TFT used in the pixel portion is a bottom-gate a-Si TFT, and the TFT used in the driver circuit portion is a bottom-gate poly-Si TFT. Here, a-Si TFT means using a-Si in the semiconductor layer, and poly-Si TFT means using poly-Si in the semiconductor layer. This is because poly-Si TFTs that operate faster because of their high mobility are advantageous in the driver circuit section, and a-Si TFTs that are easy to reduce leakage current are advantageous in the pixel section.

[0073] Figure 10 is a schematic cross-sectional view showing the structure of the second embodiment of the present invention. exist Figure 10 In the figure, the TFT on the left is a TFT used in the driver circuit section, and the TFT is formed of poly-Si. TFTs for driving circuits require high-speed operation, so poly-Si-based TFTs are used. The TFT on the right is a TFT used in the pixel portion, and the TFT is made of a-Si. This is because a small leakage current is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com