Stamping fuse structure and manufacturing method thereof

A manufacturing method and fuse technology, which are applied in fuse manufacturing, emergency protection devices, electrical components, etc., can solve the problems of difficulty in conforming to the reduction of circuit boards, large assembly volume, and troublesome manufacturing, and achieve a simplified structure, small size, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] In order to make it easier for your examining committee members to understand other features and advantages of the present invention, and the effects achieved by it can be more apparent, the present invention is described in detail as follows with accompanying drawings:

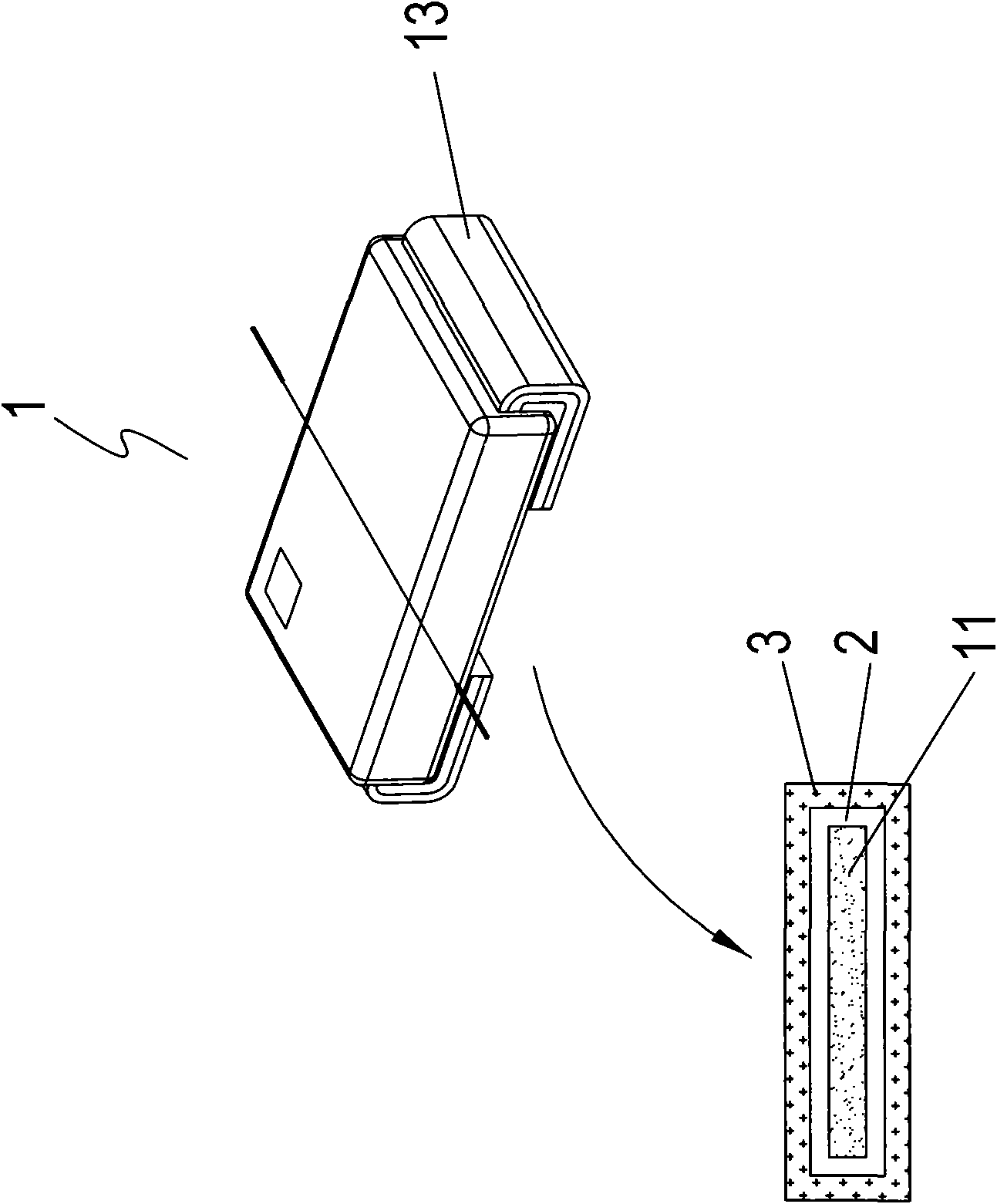

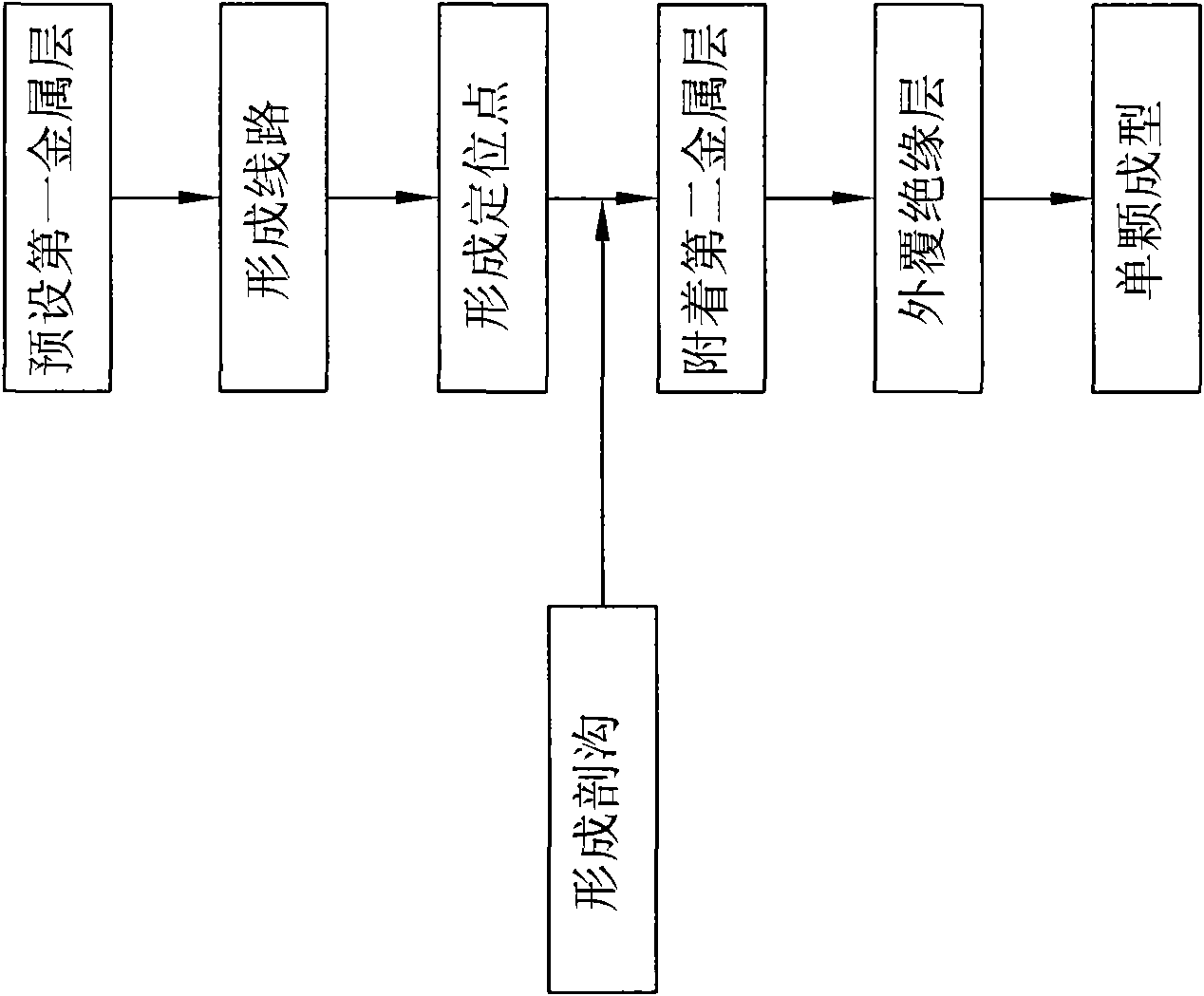

[0043] Such as Figure 1 ~ Figure 4 Shown, a kind of pressure mode fuse 1 of the present invention, its structure mainly comprises:

[0044] A fuse line 11, the middle section has a narrow fuse section 12, and the two sides are protruding electrode pins 13;

[0045] A protective layer 2 is arranged on the outer surface of the fuse line 11 in a loop shape, and;

[0046] An insulating layer 3, in the shape of a block, is coated on the middle section of the fuse line 11 that already has a protective layer 2;

[0047] Wherein said fuse line 11 is made of copper-based (95-99% by weight is copper metal) conductive material; and said protective layer 2 is made of silver, nickel, tin, etc. and alloys thereof...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com