Sea-ear deep-processing pre-treatment method

A pretreatment and deep processing technology, which is applied to the processing of crustaceans, preservation of meat/fish through freezing/cooling, slaughtering, etc., can solve the problems of reducing commodity value, distortion, high personnel costs, etc., and achieves convenient and easy meat extraction and simple production process , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

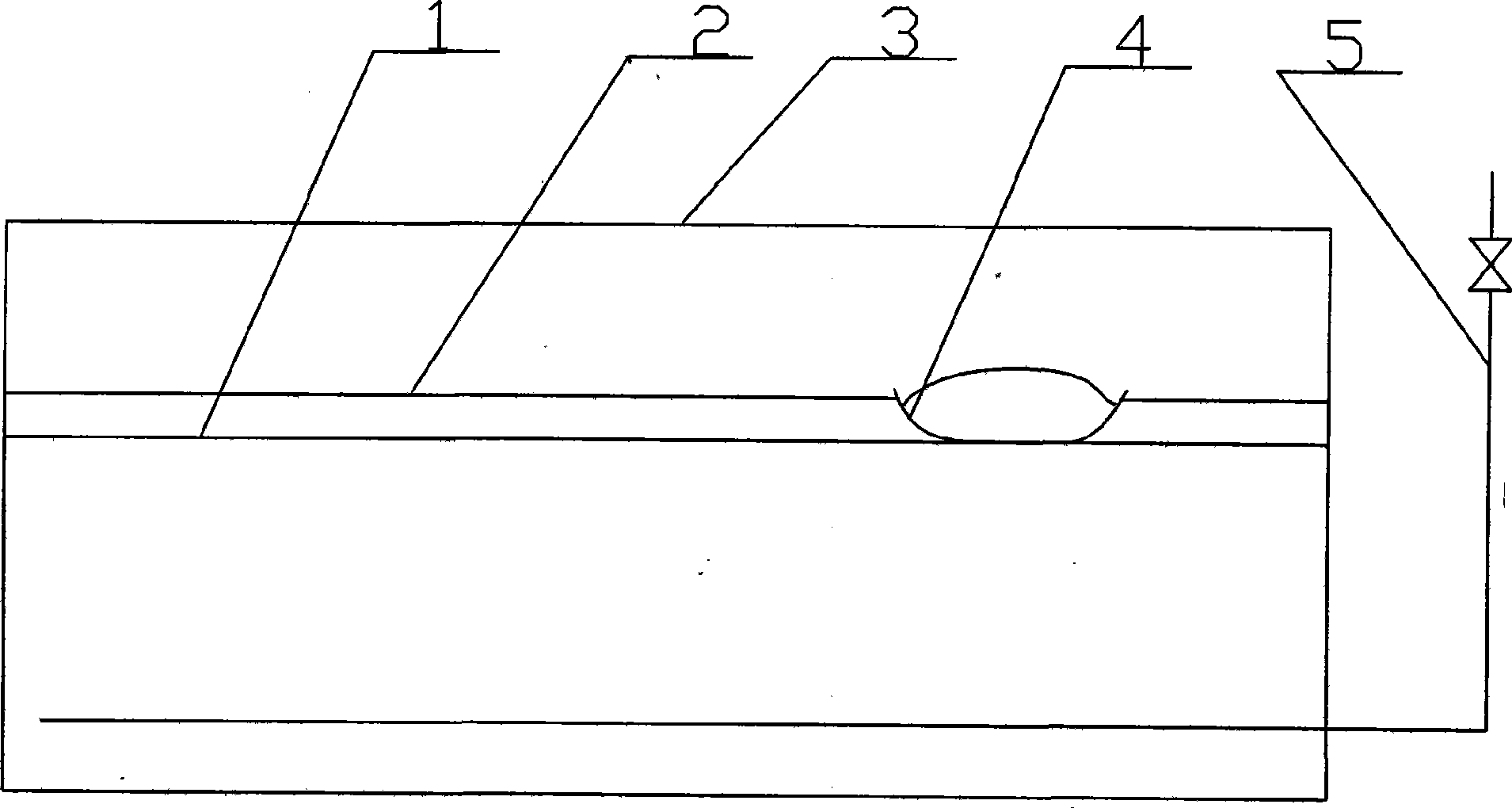

Image

Examples

Embodiment 1

[0014] (1) Shovel out the abalone from the abalone shell; specific implementation steps, ① place the abalone sucker facing up in hot water at 100°C, preferably not scalding the abalone meat, for any value between 3 and 15 seconds. During this period of time, the abalone meat is easy to shovel out, and the meat column of the abalone is not easy to be damaged, which can effectively protect the integrity of the abalone meat, and the flavor and quality of the abalone meat are better.

[0015] (2) Cold treatment: Put the shoveled abalone meat into a stainless steel bucket and push it into a fresh-keeping store for cold treatment after being fully cooled by ice water. The specific implementation steps are as follows: ①The temperature of the fresh-keeping store is 15°C and the storage time is any value between 8 and 15 hours. At this time, the abalone muscles are stiff and easy to clean. It is not easy to be damaged during the cleaning process. The product is in good condition and has...

Embodiment 2

[0019] (1) Shovel out the abalone from the abalone shell: specific implementation steps, place the abalone with the sucker facing up in hot water at 85°C so as not to scald the abalone meat. The time is any value between 16 and 35s. The abalone meat is easy to shovel out within a short period of time, and the meat column of the abalone is not easily damaged, which can effectively protect the integrity of the abalone meat, and the flavor and quality of the abalone meat are both good.

[0020] (2) Cold treatment: Store at any value between 16 and 25 hours at a temperature of 8°C in the fresh-keeping store. At this time, the muscles of the abalone are stiff and easy to clean. It is not easy to be damaged during the cleaning process. The finished product is in good condition and has raised meat columns. It has a good appearance and moderate hardness of abalone, good chewiness and flavor of abalone.

[0021] (3) Friction stirring in salt water: temperature is 55°C, salinity is 15%,...

Embodiment 3

[0024] (1) Shovel out the abalone from the abalone shell: place the abalone with the sucker facing up in hot water at 70°C so as not to scald the abalone meat. The time is any value between 36 and 60 seconds, and the abalone meat is easy to shovel out, and It is not easy to damage the meat column of the abalone, which can ensure the integrity of the abalone meat.

[0025] (2) Cold treatment: Store at any value between 26 and 40 hours at a temperature of 2°C in the fresh-keeping store. At this time, the muscles of the abalone are stiff and easy to clean. It is not easy to be damaged during the cleaning process. The finished product is in good condition and has raised meat columns. It has a good appearance and moderate hardness of abalone, good chewiness and flavor of abalone.

[0026] (3) Friction stirring in salt water: temperature 70°C, salinity 20%, the ratio of abalone meat to salt water 1:3, mechanical stirring speed 8r / s, make the abalone meat rub against each other for 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com