Structural principle of an energy-saving pot and manufacture process for the same

A technology of structural principle and manufacturing process, which is applied in the fields of kitchen utensils, energy efficient utilization and mechanical manufacturing, can solve the problems of small contact area, short contact time, and low heat utilization, so as to increase the heating area, save energy, and reduce heat. Dissipated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The structural principle and manufacturing process of an energy-saving pot according to the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

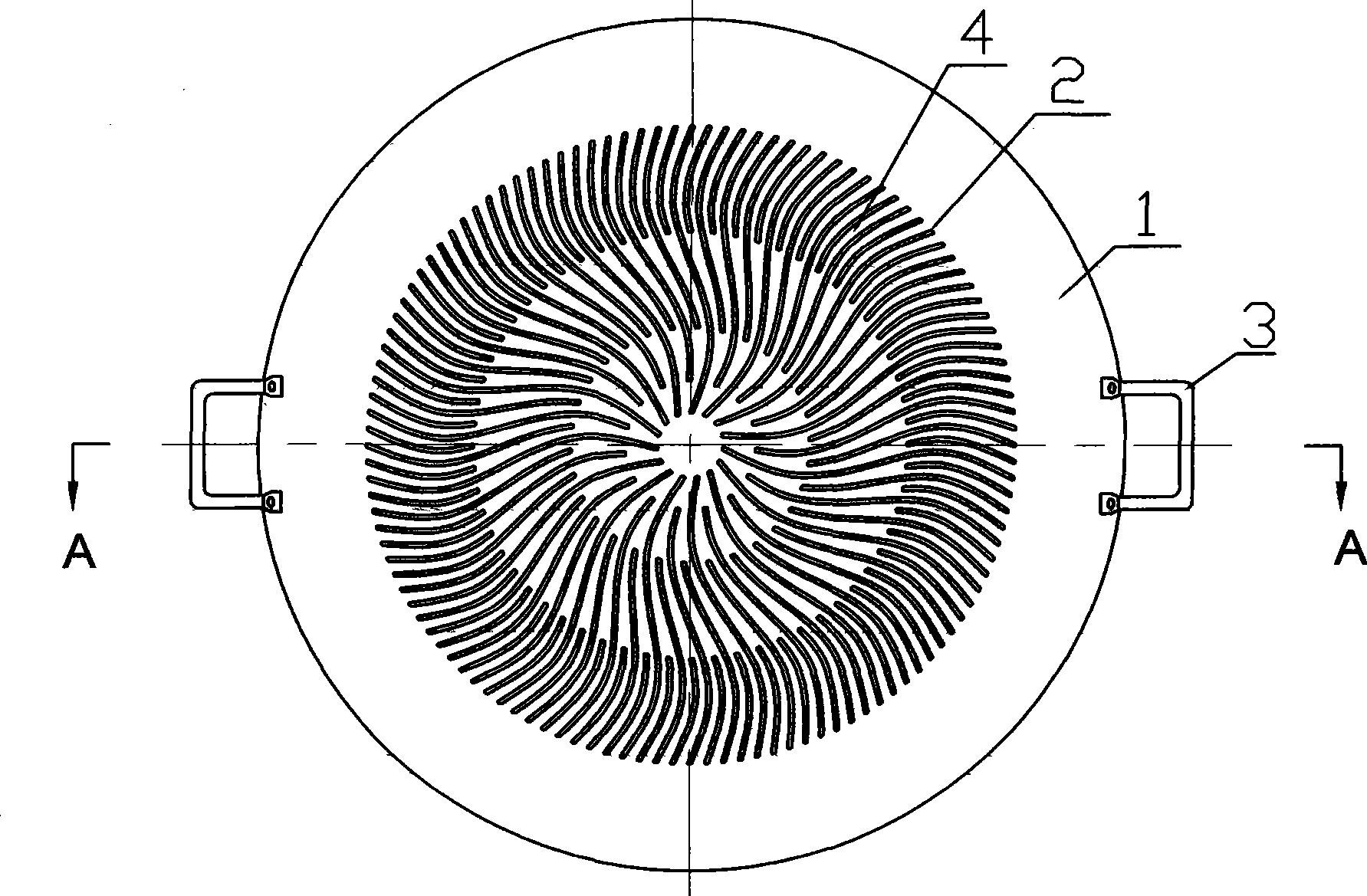

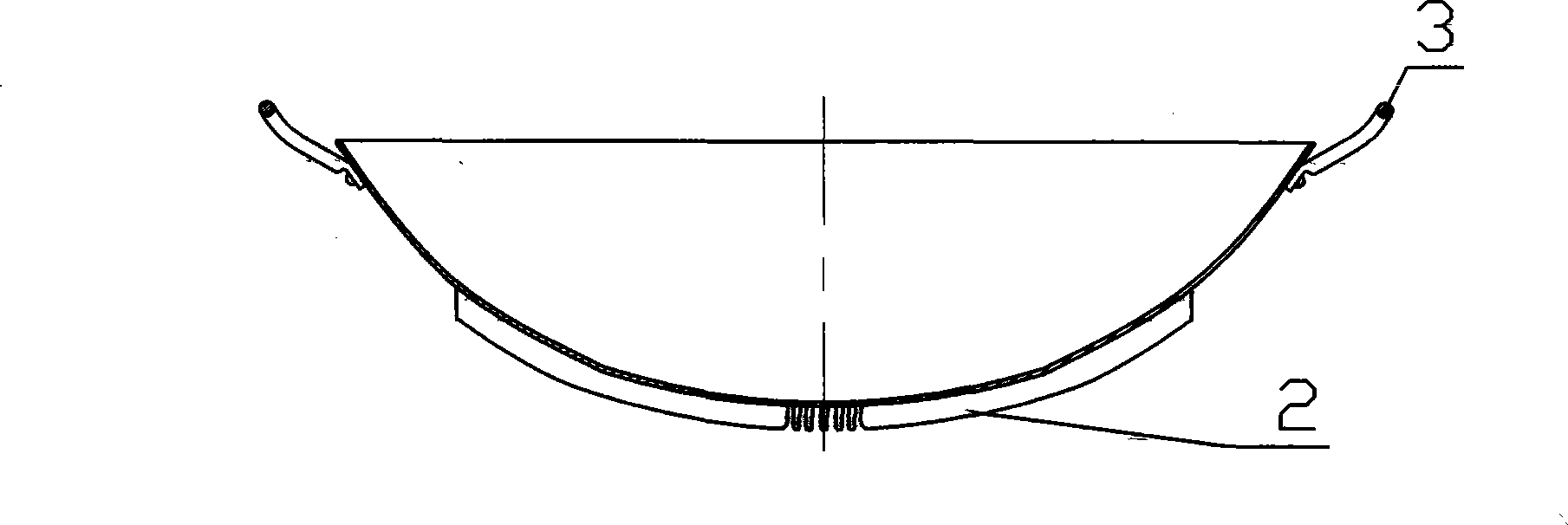

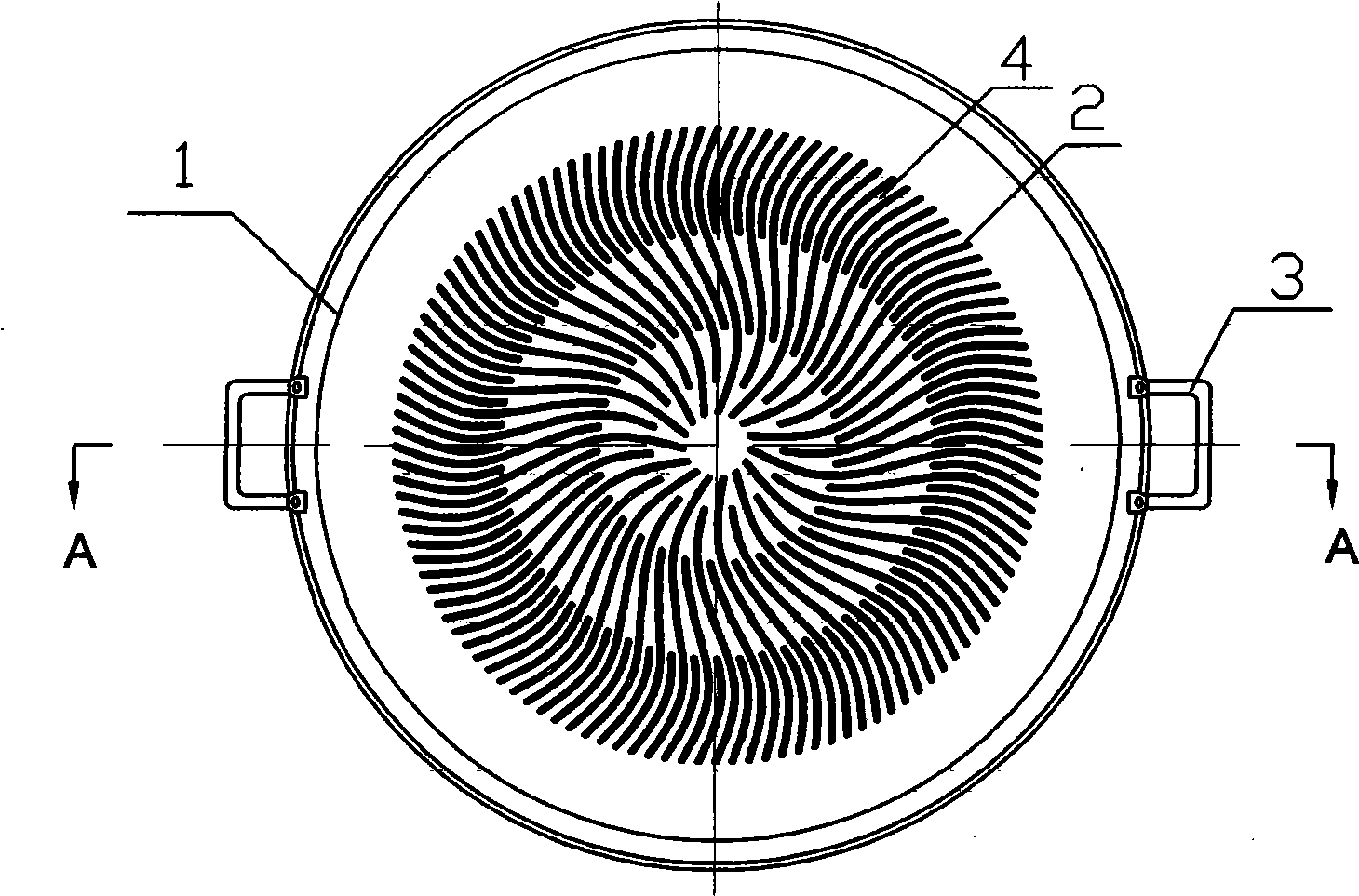

[0025] as attached figure 1 , 2 Shown: attached figure 1 It is a structural schematic diagram of a hemispherical shape at the bottom of the pot for implementing the structural principle of an energy-saving pot of the present invention. figure 2 to attach figure 1 The cross-sectional view of A-A in the figure shows that an energy-saving pot of the present invention includes a pot body 1, a heat collecting sheet 2, and a handle 3. The bottom of the pot has a hemispherical structure, and millimeter-scale heat collectors 2 are cast at a distance of 20mm from the center of the heating surface of the bottom of the pot. The heat collectors 2 are corrugated, extending from sparse to dense to the edge, and expanding in multiples The method surrounds the surface ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com