Portable taper gauge for measuring crystallizer and working process thereof

A portable and crystallizer technology, applied in the configuration of indicating equipment/measuring equipment, measuring devices, instruments, etc., can solve the problems of too many interference factors, complex circuits, complex structures, etc., and achieve wide adaptability, accurate data, and structural simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0053] 1. Portable taper meter

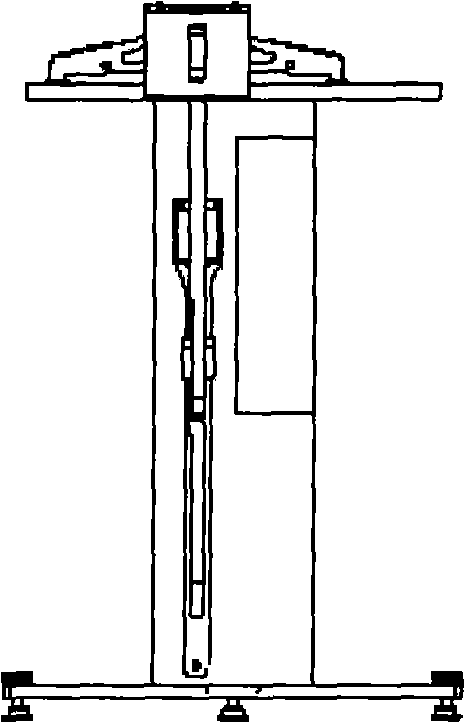

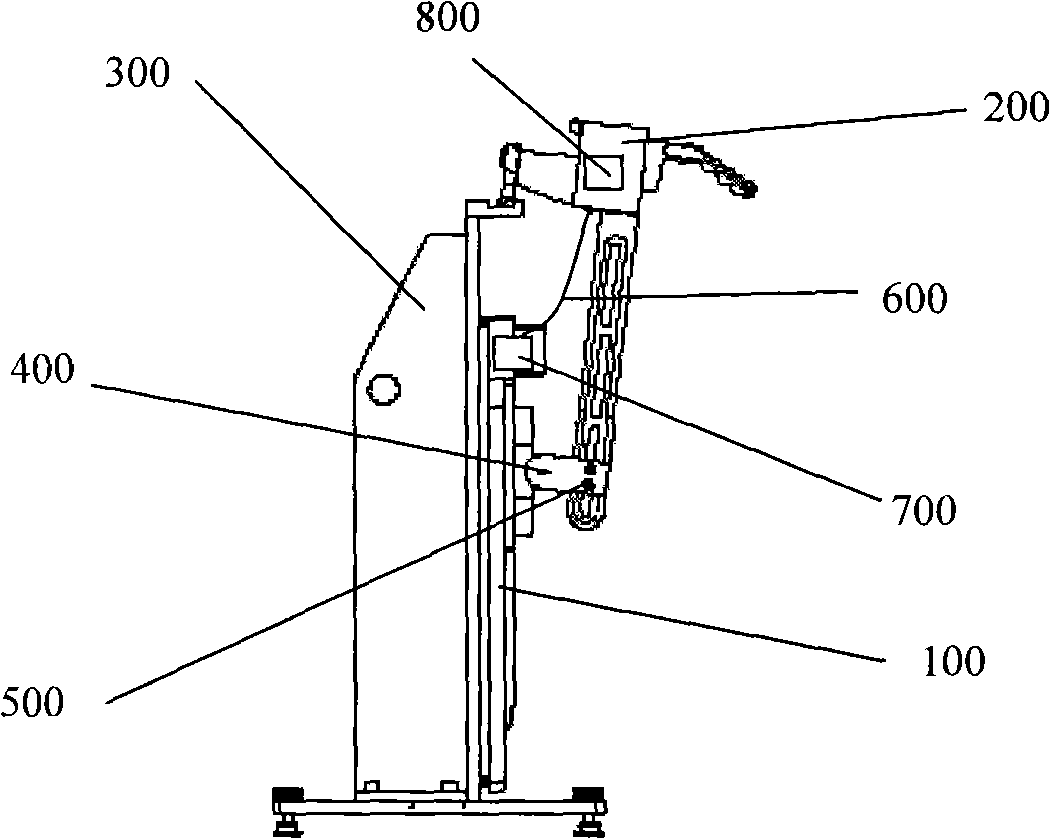

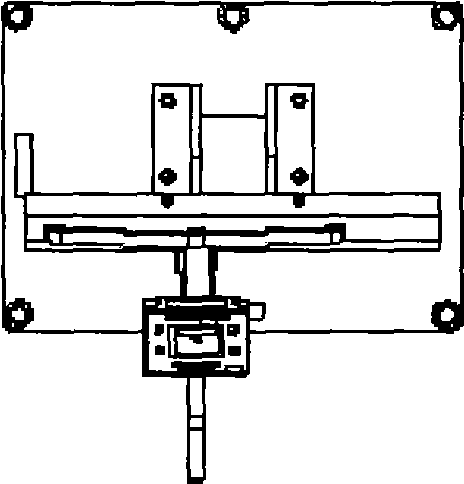

[0054] 1. Overall

[0055] Such as Figure 1.1 , 1.2 , 1.3, the portable taper meter is composed of a sensor bracket 100, a column display box 200, a calibration platform 300, a connecting platen 400, an inner hexagon bolt 500, a spiral cable 600, an inclination sensor 700 and a digital display circuit 800;

[0056] The calibration platform 300 and the sensor bracket 100 are connected as a whole;

[0057] The column display box 200 is placed on the calibration platform 300, and connected to the sensor bracket 100 through the connecting platen 400 and the hexagon socket bolt 500;

[0058] The inclination sensor 700 is placed on the sensor bracket 100, and the digital display circuit 800 is placed inside the column display box 200;

[0059] The inclination sensor 700 and the digital display circuit 800 are electrically connected through a spiral cable 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com