Energy-saving full-function refrigeration cycle system

A circulation system and full-function technology, which is applied in the field of energy-saving full-function refrigeration cycle system, air-conditioning equipment, and energy-saving constant temperature and humidity unit, can solve the problems of low energy efficiency ratio, high energy consumption, and high energy consumption of constant temperature and humidity machines. Achieve high energy efficiency ratio, low energy consumption, and improve the effect of annual performance coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

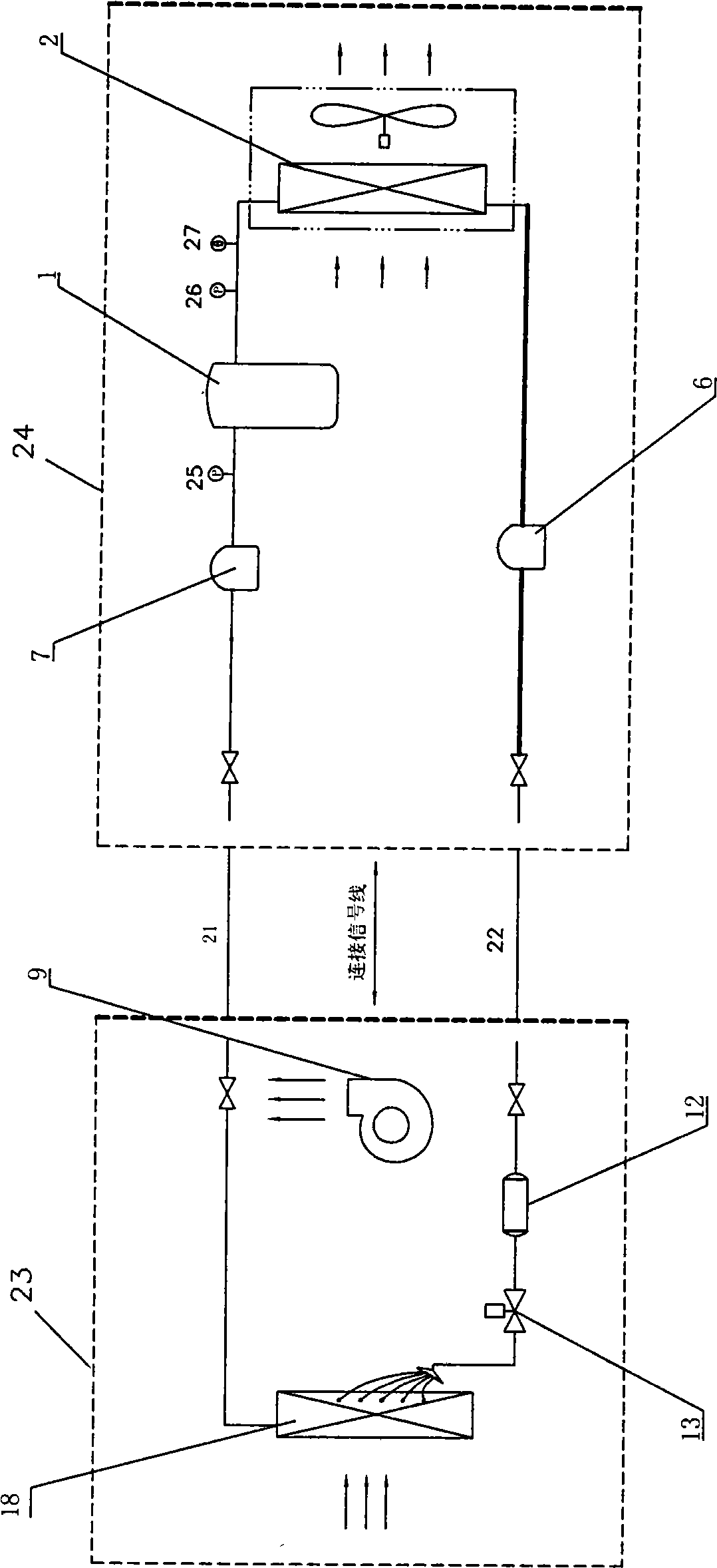

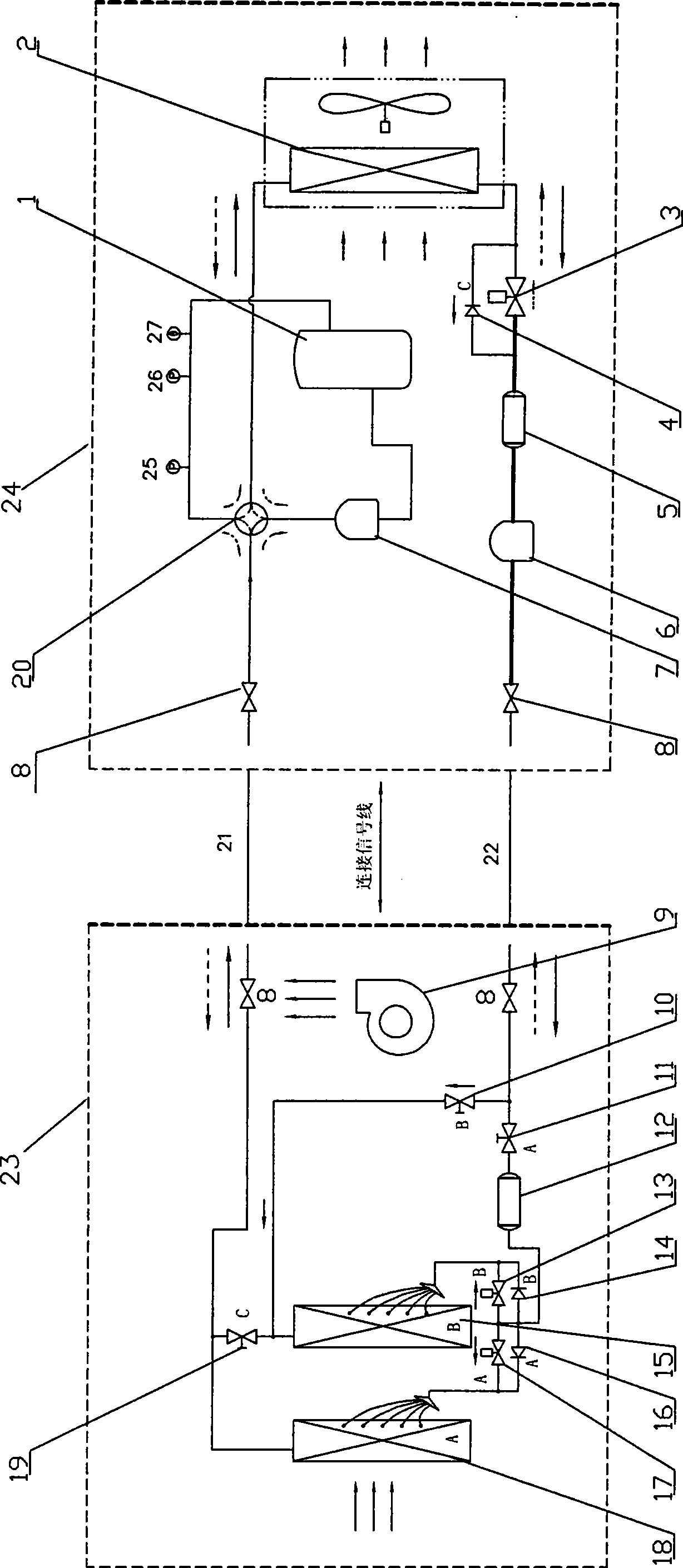

[0024] like figure 2 shown.

[0025] An energy-saving full-function refrigeration cycle system, including an indoor unit 23 and an outdoor unit 24, the indoor unit 23 and the outdoor unit 24 are connected through a gas pipeline 21 and a liquid pipeline 22, and the outdoor unit 24 is mainly composed of a compressor 1, an outdoor replacement Heater 2 (air-cooled heat exchanger or water-cooled heat exchanger can be used), vapor-liquid separator 7, heating expansion valve 3, check valve C4, heating drying filter 5 and four-way reversing valve 20, the The output end of the compressor 1 is connected to one input end of the four-way reversing valve 20, and the three output ends of the four-way reversing valve 20 are respectively connected to the outdoor heat exchanger 2, the vapor-liquid separator 7 and the outdoor unit 24 It is connected to the input end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com