Radio frequency induction lamination level sensor

A radio frequency induction and sensor technology, applied in instruments, liquid level indicators, machines/engines, etc., can solve the problem that the material level sensor cannot measure multi-phase material level, and achieve the effect of eliminating measurement blind spots and improving measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

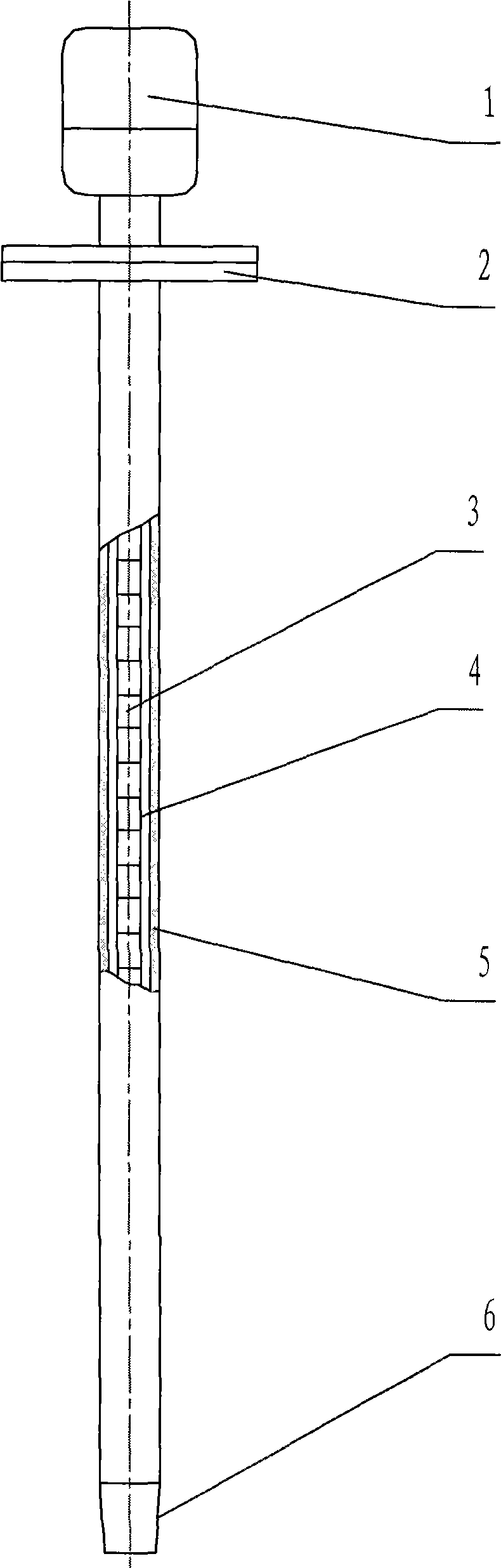

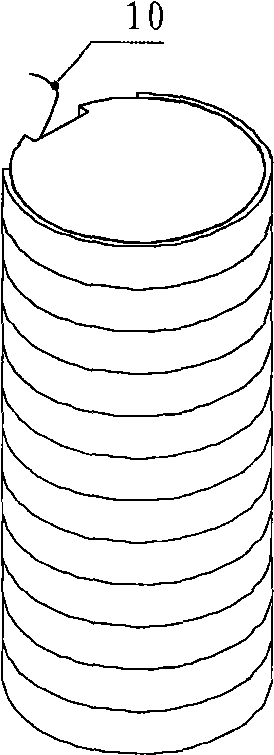

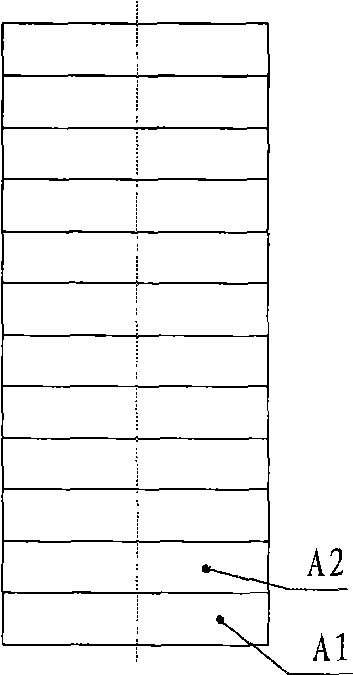

[0057] Such as figure 1 , figure 2 , diagram 2-1 , Figure 2-2 , Figure 2-3 As shown, the measuring electrode of this embodiment is supported by a columnar insulator 4. The columnar insulator 4 is a rigid body or a flexible body. The outer surface of the columnar insulator 4 is equidistantly stacked and arranged with single-way mutual insulation, the same shape and size. The electrode 3 is coated with insulating glue on the outer layer of the measuring electrode and put into the insulating sleeve 5. The upper end of the insulating sleeve 5 is connected to the flange plate 2, and the lower end is connected to the sealing hammer 6. Each electrode 3 is connected to a shielded cable 10, and the electrode 3 It is an arc-shaped structure made of double-sided insulated metal sheet. The columnar insulator 4 at the opening position of the arc-shaped electrode 3 is processed with a wire groove 8, and all shielded cables 10 are embedded in the wire groove 8, and pass through the fl...

Embodiment 2

[0060] Such as figure 1 , Figure 3-1 , Figure 3-11 , Figure 3-12 , Figure 3-13 , Figure 6-1 , Figure 6-11 As shown, the measuring pole of this embodiment is supported by a columnar insulator 4, the columnar insulator 4 is a rigid body or a flexible body, and the electrodes 3 are arranged in two ways at an angle of 180 degrees along the longitudinal axis of the columnar insulator 4 and arranged at equal distances, each of which is adjacent The two electrodes 3 have the same shape and size, are insulated from each other, and are laid in equidistant layers. The electrodes 3 are arc-shaped and made of double-sided insulated metal sheets. The outer layer of the measuring electrode is coated with insulating glue and then put into an insulating sleeve. The upper end of the pipe 5 and the insulating sleeve 5 are connected to the flange 2, and the lower end is connected to the sealing hammer 6. Each electrode 3 is respectively connected to a shielded cable 10, and the column...

Embodiment 3

[0063] Such as figure 1 , Pic 4-1 , Figure 4-11 , Figure 4-12 , Figure 4-13 , Figure 7-1 , Figure 7-11 As shown, the measuring pole of this embodiment is supported by a columnar insulator 4. The columnar insulator 4 is a rigid body or a flexible body. The electrodes 3 are arranged in three lines at intervals of 120 degrees along the longitudinal axis of the columnar insulator 4. Each line is adjacent to each other. The two electrodes 3 have the same shape and size, are insulated from each other, and are laid in equidistant layers. The electrodes 3 are arc-shaped and made of double-sided insulated metal sheets. The outer layer of the measuring electrode is coated with insulating glue and then put into an insulating sleeve. The upper end of the pipe 5 and the insulating sleeve 5 are connected to the flange 2, and the lower end is connected to the sealing hammer 6. Each electrode 3 is respectively connected to a shielded cable 10, and the columnar insulator 4 between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com