Method for measuring nonlinearity of material based on monopulse

A nonlinear, single-pulse technology, applied in the field of nonlinear photonics materials and nonlinear optical information processing, can solve the problems of high measurement cost, sample damage, complex processing, etc., and achieve small damage, simple measurement method, and simple processing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

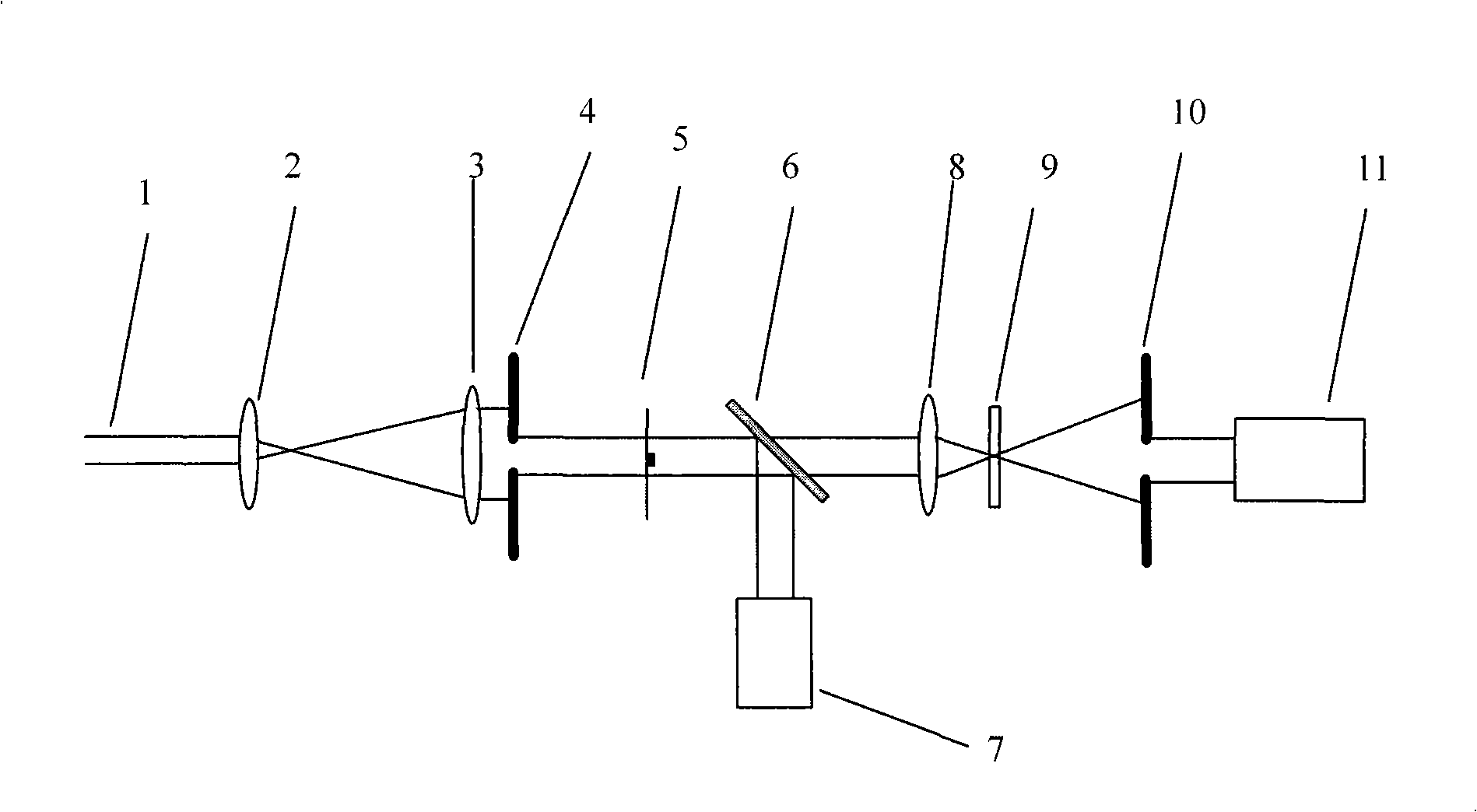

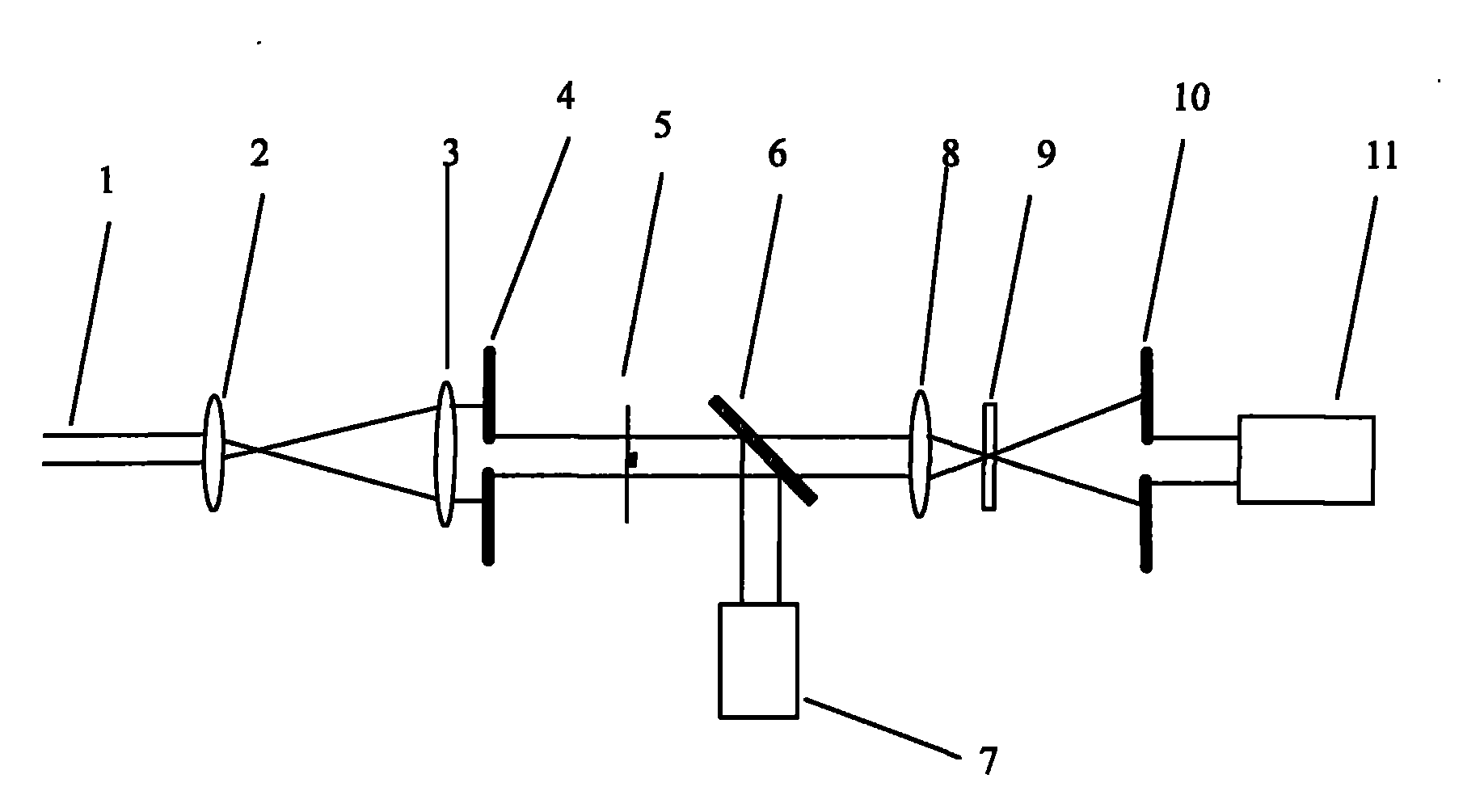

[0022] Embodiment one: see attached figure 2 As shown, a method for measuring optical nonlinearity with single-pulse Tophat light, the optical path is composed of a beam expander lens, an aperture, a beam splitter, a phase object, a focusing lens, a small hole and a detector; the pulse laser is focused on the sample to be measured .

[0023] The incident laser beam 1 passes through the beam expander system composed of two beam expander lenses 2 and 3 and the aperture 4 to form an approximate Tophat-type laser pulse. The laser pulse is divided into two beams by the beam splitter 6. The energy of the monitoring light is determined by the first Received by the detector 7 , another beam of light is focused by the focusing lens 8 onto the sample 9 to be tested, and the transmitted beam passes through the aperture diaphragm 10 and is received by the second detector 11 .

[0024] In this embodiment, the laser beam is a 532nm laser after frequency doubling by a Nd:YAG laser (Ekspla,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hysteresis loss | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com