Method for online separately detecting resistive leakage current of non-voltage reference source

A resistive current and leakage current technology, applied in the measurement of current/voltage, measuring device, RMS measurement, etc., can solve the problems of thermal collapse of arrester, power failure, increase of resistive current component, etc., to achieve enhanced effectiveness and efficiency. Accuracy, the effect of improving reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail through specific embodiments below.

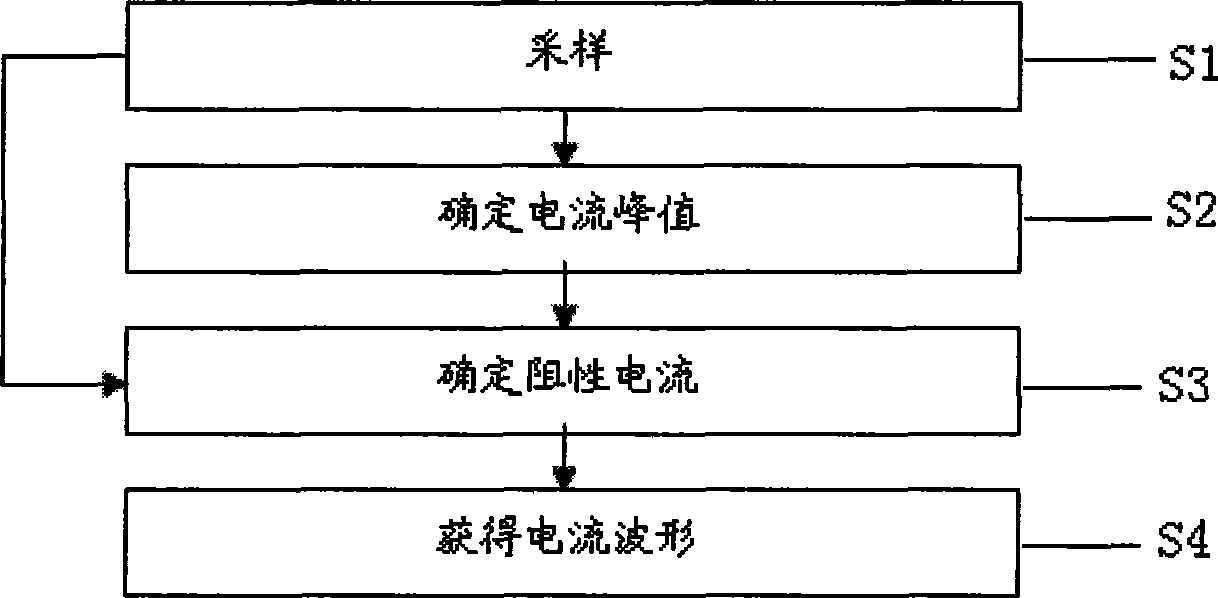

[0016] A method for on-line separation and detection of resistive leakage current without a voltage reference source, comprising the following steps:

[0017] Sampling step S1, sampling a fixed-period surge arrester leakage full-current period signal;

[0018] Determine the current peak value step S2, determine the peak value of the capacitive current according to the leakage full current period signal sampled in the sampling step S1, the current peak value is obtained by finding the first value of the monotonically increasing function in one period of the full wave signal of the leakage full current signal A positive extreme point, and it is realized as the peak value of the capacitive current;

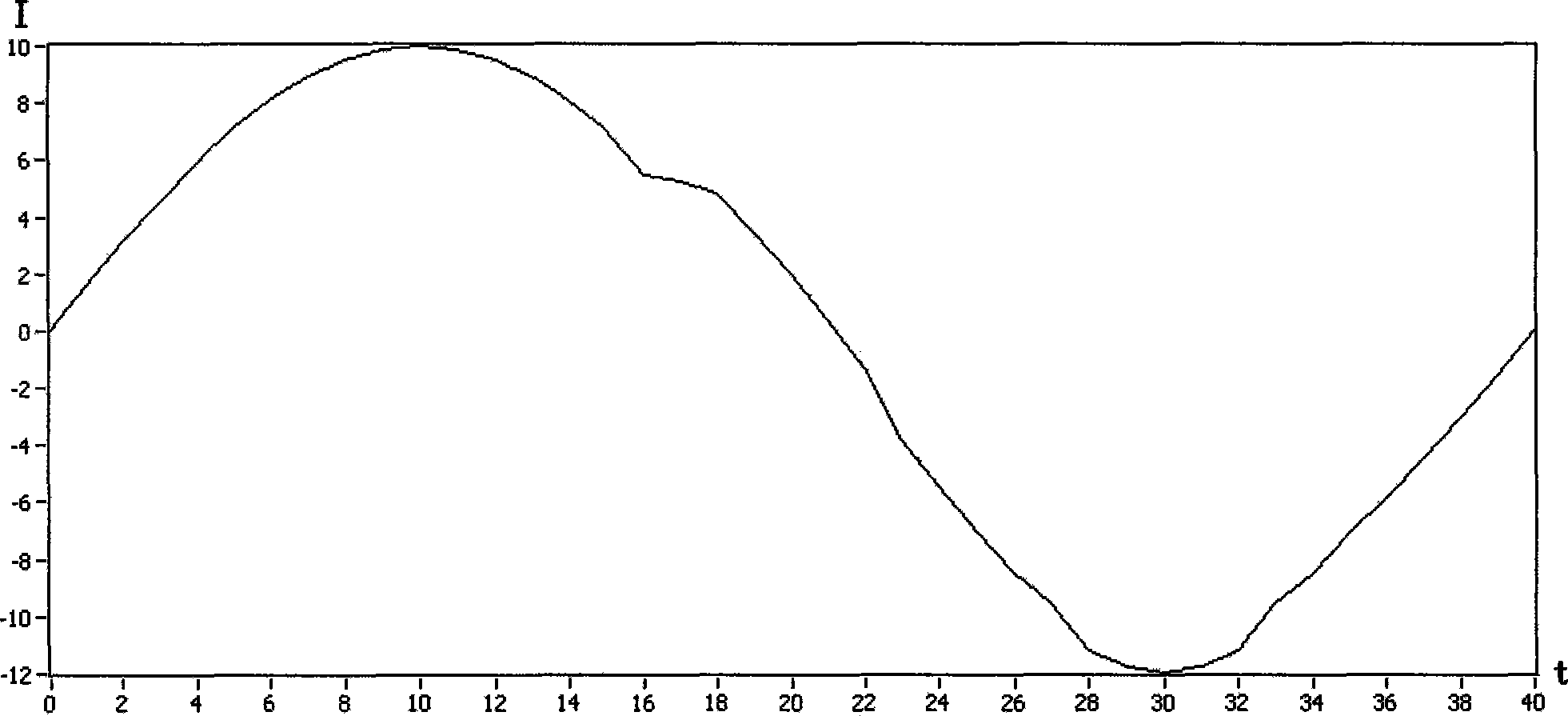

[0019] Determine the resistive current step S3, according to the leakage full current cycle signal sampled in the sampling step S1 and the peak value of the capacitive current dete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com