Lightning protection layer stranded optical cable

A layer-twisted, lightning-proof technology, which is applied in the direction of fiber mechanical structure, can solve the problems of optical fiber damage, optical cable breakdown, communication interruption, etc., and achieve the effects of reliable work, guaranteed tensile strength, and prevent damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

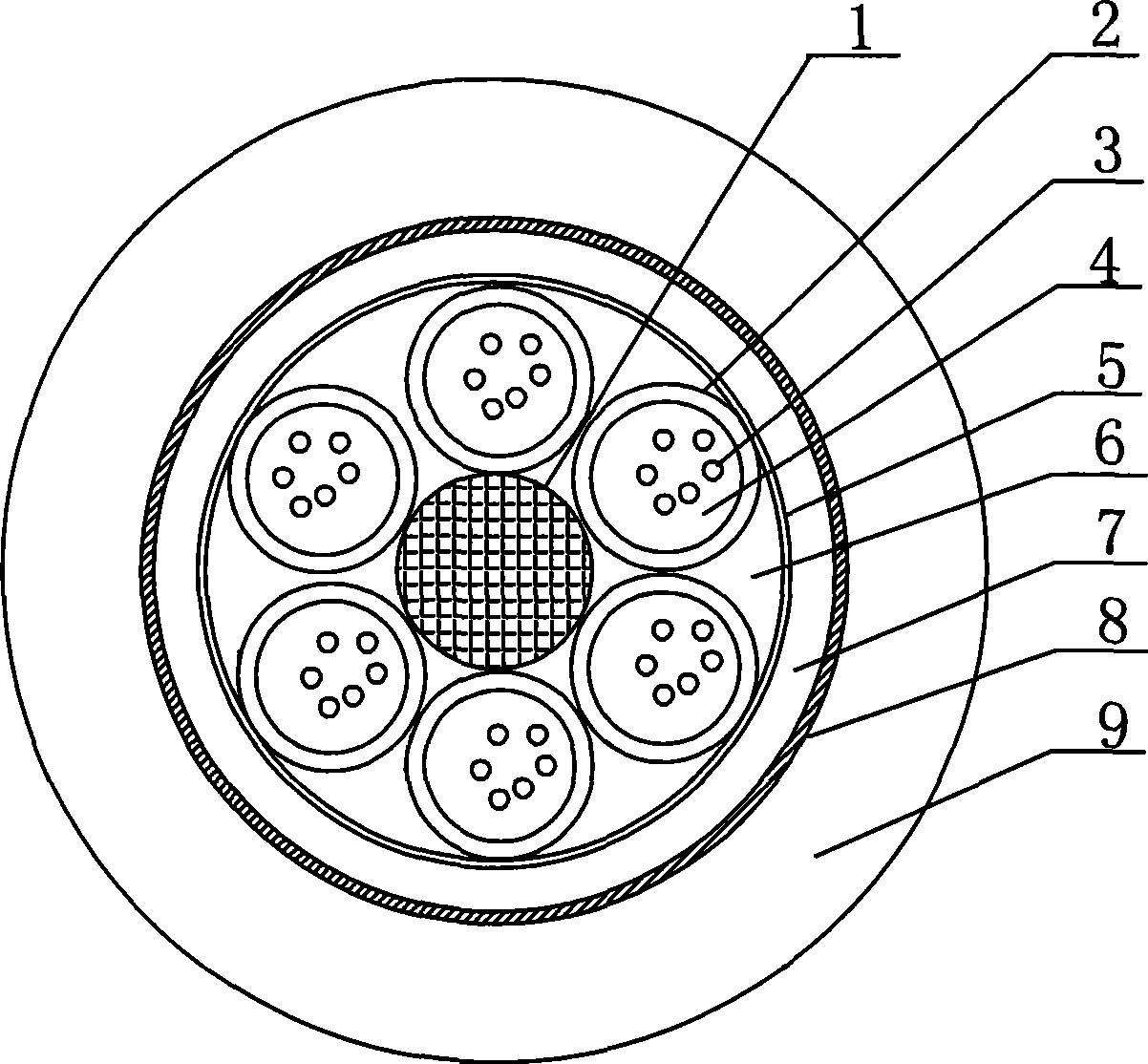

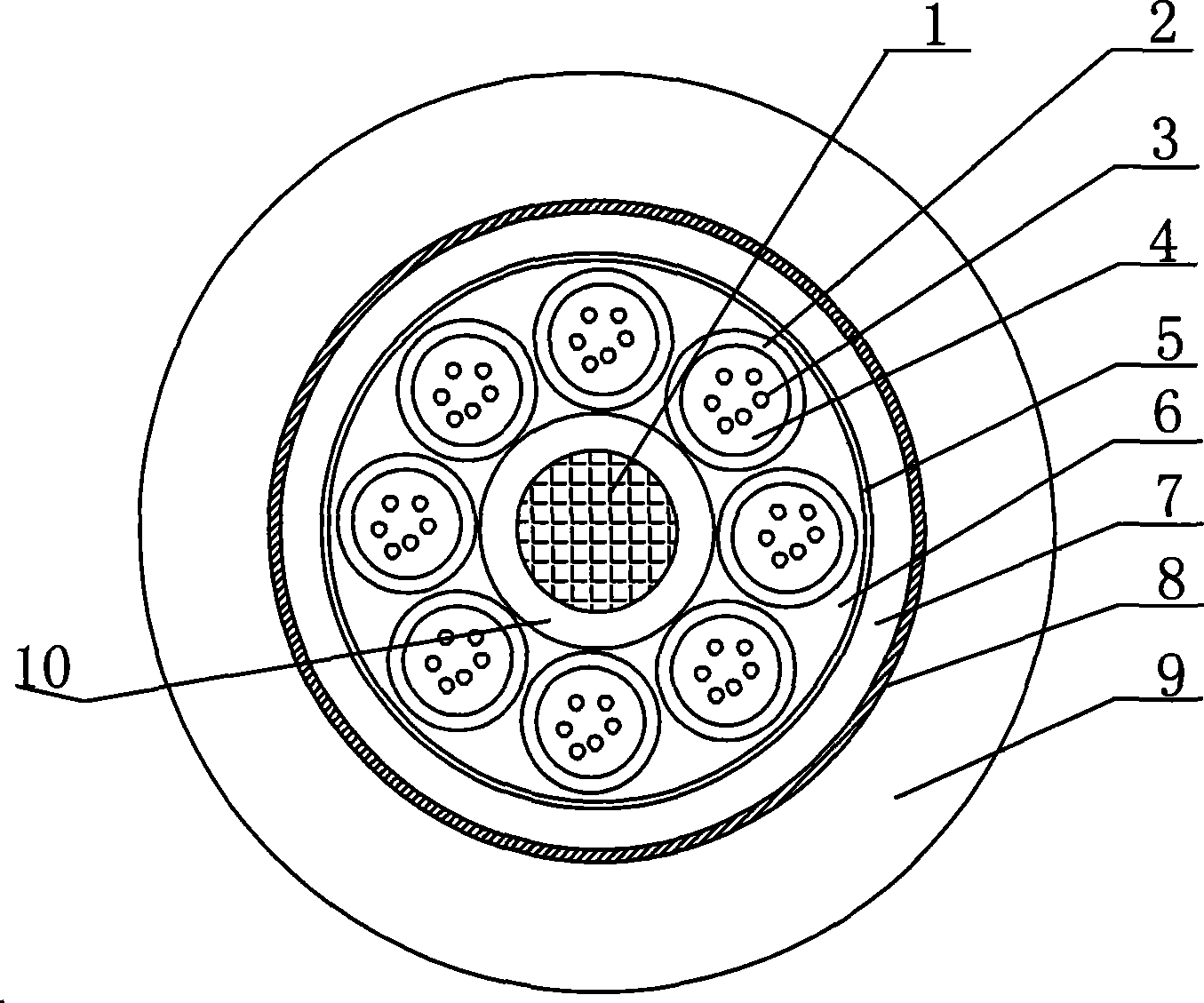

[0015] figure 1 is a cross-sectional view of the invention where the reinforcing core is a single glass fiber reinforced plastic rod. As shown in the figure, it is a layer-stranded optical cable for lightning protection, including a cable core and a sheath placed outside the cable core. The cable core includes a strengthening core 1 and at least one loose tube twisted around the strengthening core. 2 and its built-in optical fiber 3 and the fiber bundle tube formed by filling the fiber paste 4. In this example, the cable core includes 6 fiber bundle tubes. The above-mentioned sheath includes a yarn binding layer 5, a steel-plastic composite layer 8 and an outer sheath 9; the above-mentioned yarn binding layer 5, steel-plastic composite layer 8 and outer sheath 9 are coated on the cable core in sequence from the inside to the outside, and the waterproof cable The paste 6 is filled between the cable core and the yarn binding layer; the feature is that the above-mentioned reinfo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com