Battery spring connection structure

一种弹簧连接、电池的技术,应用在连接、连接装置的零部件、固定/绝缘接触构件等方向,能够解决电池弹簧脱落、电池接触不良、簧圈无法接触等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The battery spring connection structure of the present invention will be further described in detail below in conjunction with preferred embodiments and accompanying drawings.

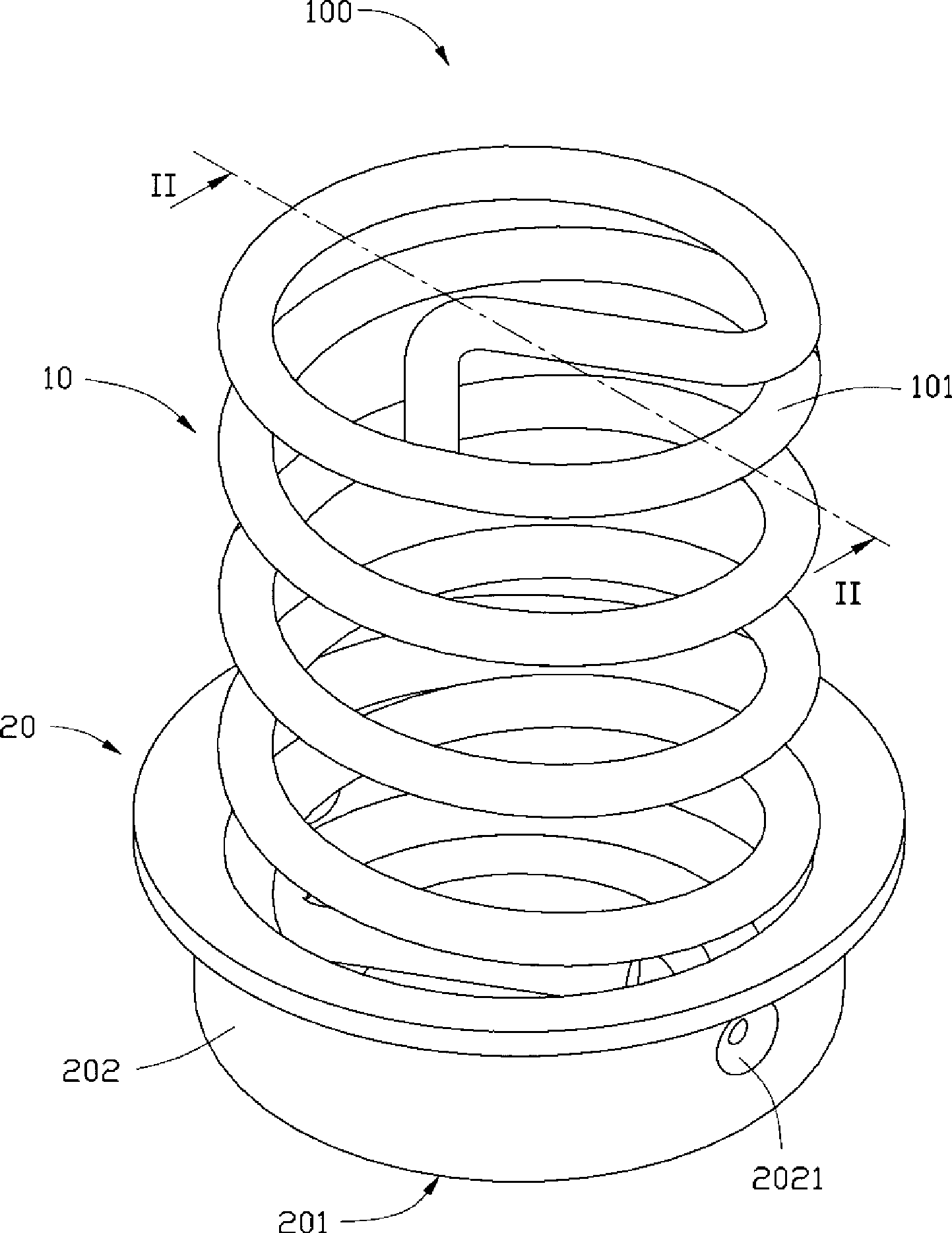

[0015] See figure 1 and figure 2 , The battery spring connection structure 100 of the preferred embodiment 1 of the present invention can be used in the battery slot of an electronic product to install the battery and push the battery so that the electrodes are in close contact with the metal contacts in the battery slot to conduct current. The spring connection structure 100 includes a battery spring 10 and a contact cover 20 connected to the battery spring 10 . The battery spring 10 includes a plurality of helical coils 101 . Both the coils 101 at the top and the coils 101 at the bottom of the battery spring are bent inward to avoid damaging the battery and the contact cover 20 .

[0016] The contact cover 20 is made of phosphor bronze by stamping and deep drawing, and includes a bottom pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com