Electronic component package

A technology for electronic components and packages, which is applied in the direction of electrical components, electrical solid devices, semiconductor/solid device parts, etc., can solve problems such as crushing of protrusions 914, peeling off of metal plating, scattering of metal particles, etc., and achieves suppression of spattering, The effect of suppressing the generation of spatter

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

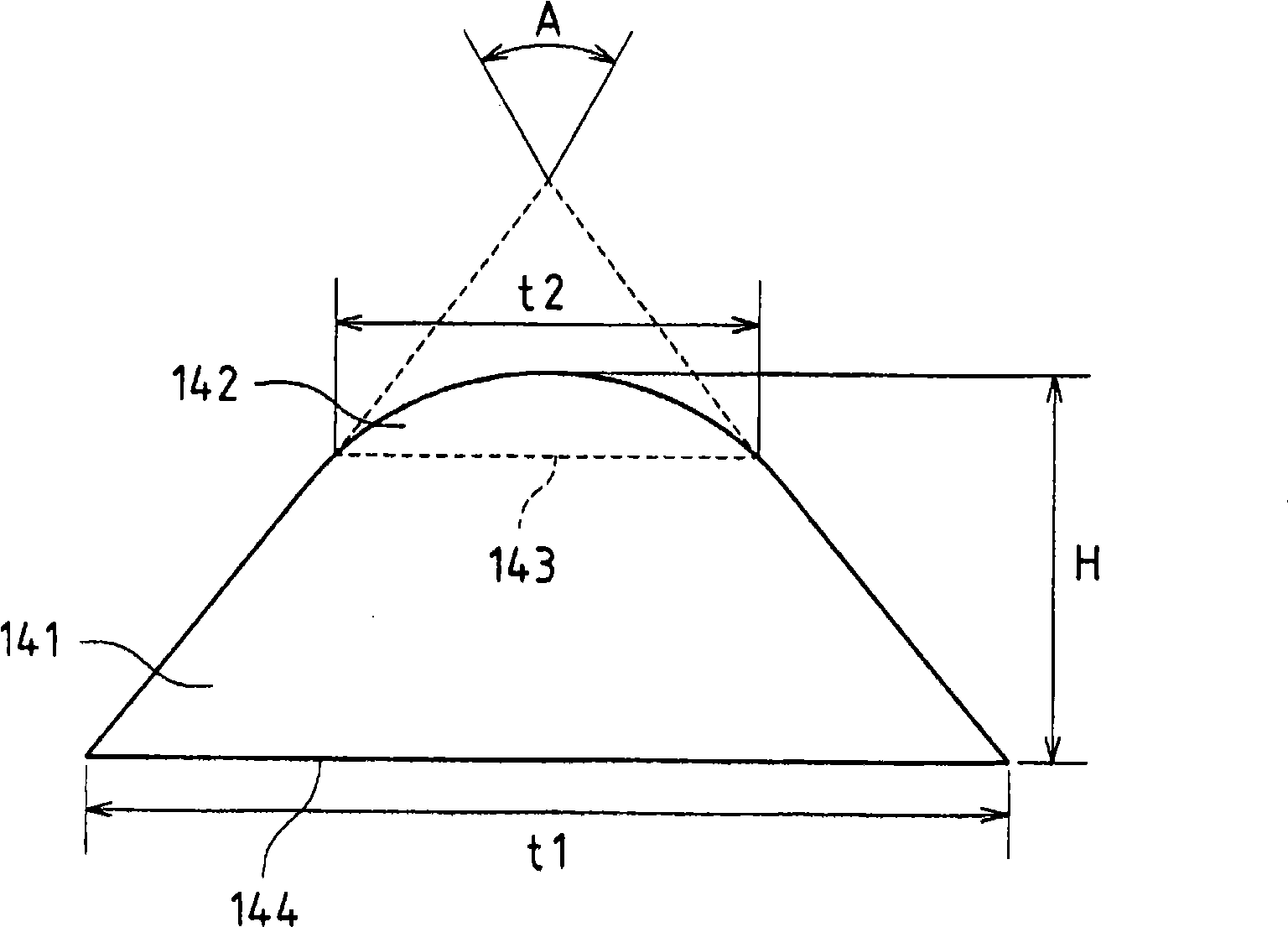

Above-mentioned protrusion 14 can not only be defined by the setting of the apex angle A formed by the equilateral extension line of the protrusion, but can also be defined as Figure 4 As shown, it is defined by the size ratio of the upper side 143 and the lower side 144 of the trapezoidal portion 141 . For example, the width dimension t2 of the upper edge 143 of the trapezoidal portion 141 is set as 25% to 40% of the width dimension t1 of the bottom edge 144, so that the dimension t1 of the bottom edge 144 of the trapezoidal portion 141 is 0.182mm, relative to this dimension t1 By setting the dimension t2 of the upper side 143 of the trapezoidal portion 141 to 0.0455 mm to 0.0728 mm, the same spatter suppression effect as in the above-described embodiment can be expected. That is, by setting the width dimension of the upper side 143 of the trapezoidal portion 141 to 25% to 40% of the width dimension of the bottom side 144, the state in which the welding current during resista...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com