Soy milk heating method and soy milk grinder using the heating method

A heating method and technology of a soymilk machine, applied in applications, home appliances, kitchen utensils, etc., can solve the problems of inconvenient manufacturing, complex structure of a soymilk heating device, and high manufacturing cost, so as to avoid overflowing the pot, have a good taste of soymilk, and be convenient to manufacture Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

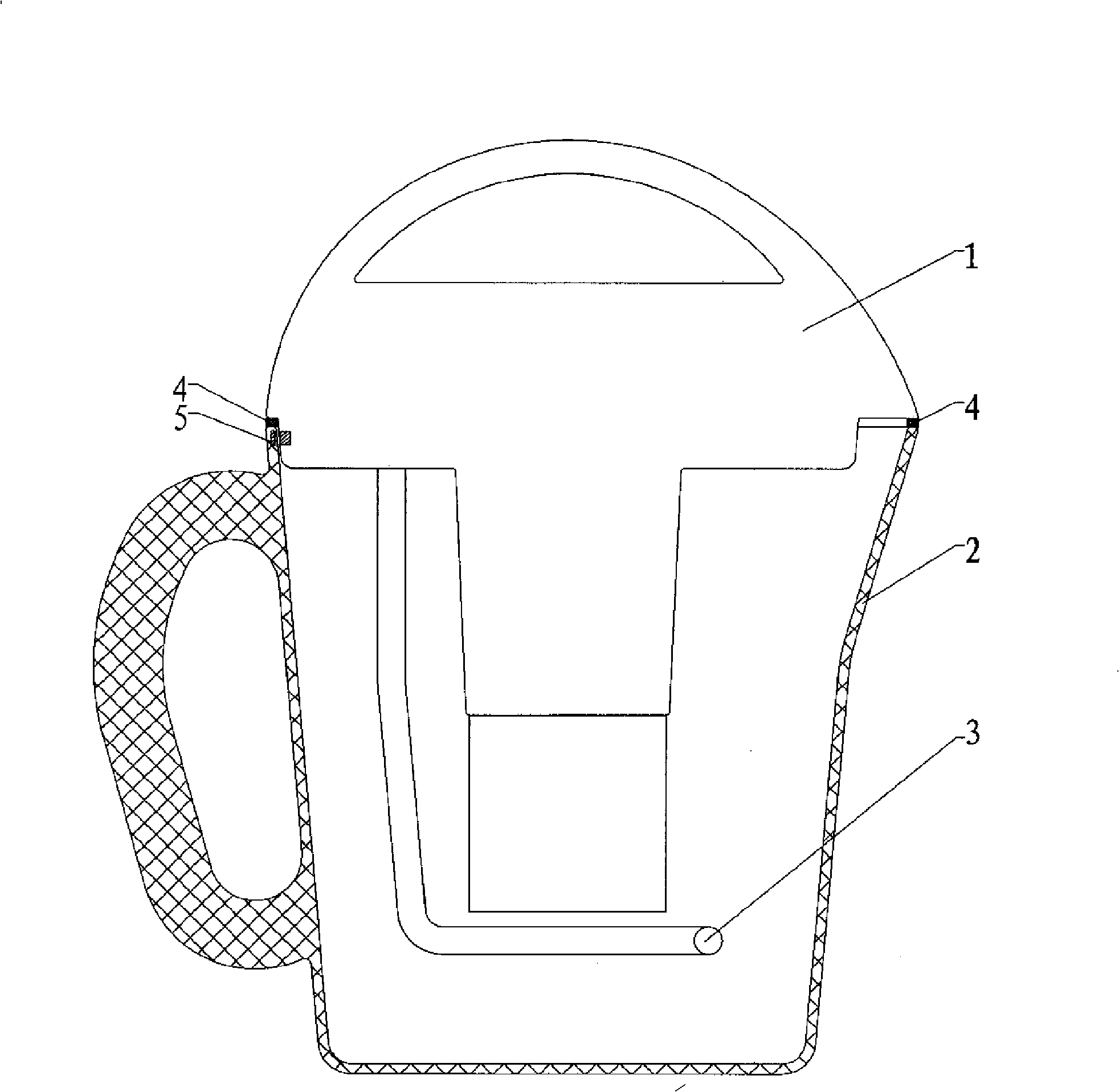

[0017] Such as figure 1 As shown: the soybean milk machine in this embodiment includes: the machine head 1 of the soybean milk machine is buckled on the barrel body 2, a motor is installed in the machine head, and a stirring blade is connected to the lower end of the output shaft of the motor. When the machine head is installed on the barrel body, the stirring blade Located in the barrel body; the heater 3 is connected to the machine head, and when the machine head is installed on the barrel body, the heater extends into the barrel body 2; a sealing ring 4 is arranged between the barrel body and the machine head. A safety switch 5 is provided between the machine head and the staving.

[0018] The soya-bean milk machine of present embodiment is owing to adopt the sealing ring between barrel body and machine head to realize sealing between barrel body and machine head; Can form the pressure that is higher than atmospheric pressure 21-30 kilopascals in the heating container and b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap