Special filter plate for diatomite

A diatomite and filter plate technology, which is applied in the fields of filtration and separation, fixed filter element filters, chemical instruments and methods, etc., achieves the effects of remarkable effect, improved work efficiency, and great popularization and application value.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The technical content of the present invention will now be described in detail in conjunction with the accompanying drawings.

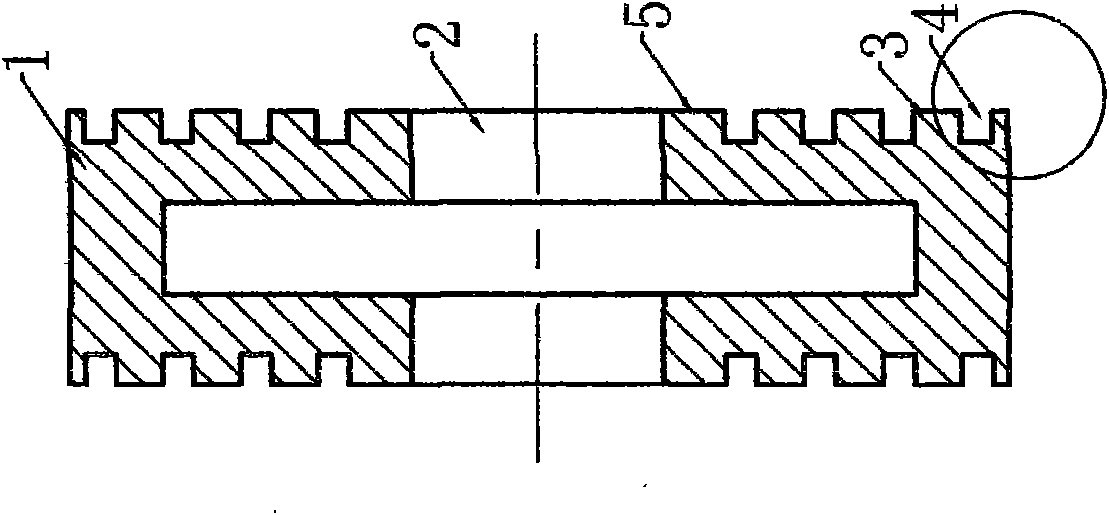

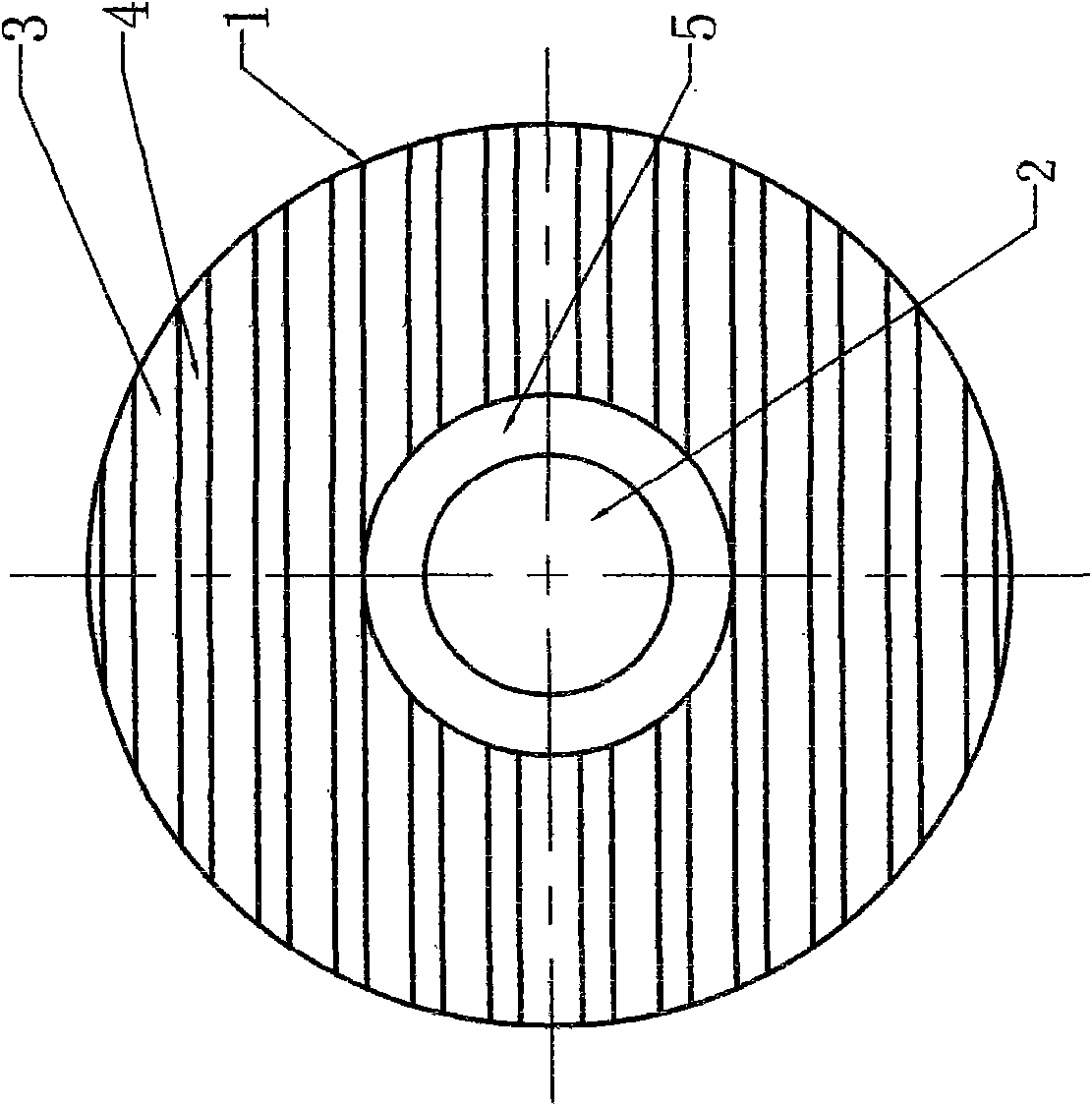

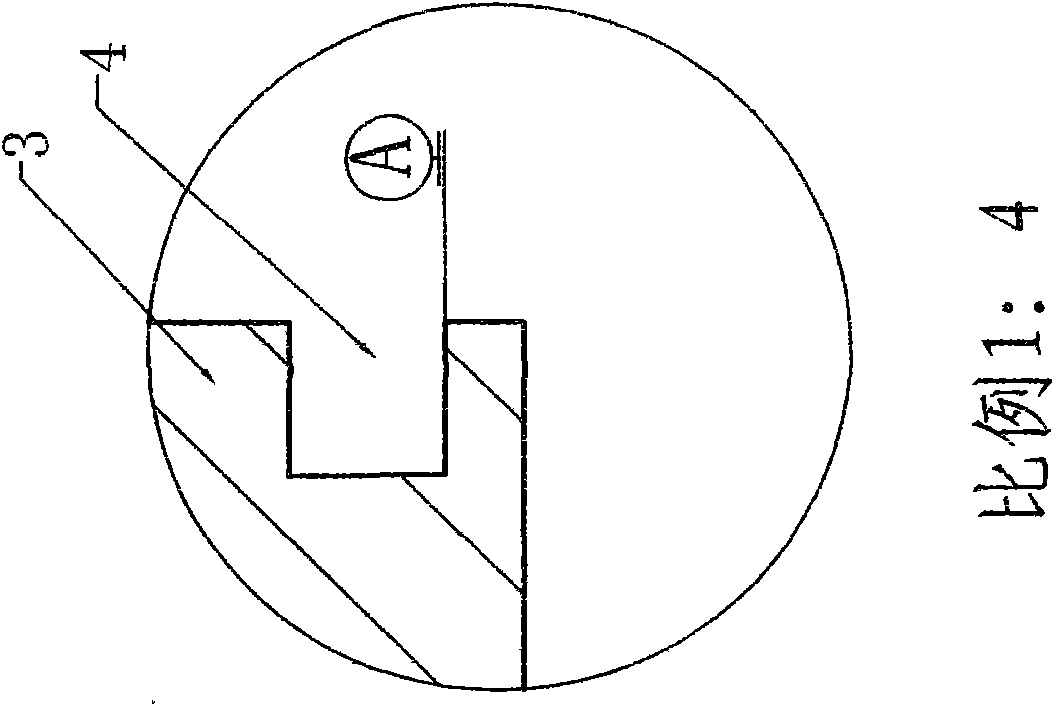

[0010] The filter plate 1 is hollow, and the center of the filter plate 1 is provided with a connecting hole 2. The two sides of the filter plate 1 are provided with a circular sealing surface 5 adjacent to the central hole 2. The two sides of the filter plate are provided with several parallel convex holes. Strip 3. A diatomite accumulation groove 4 is formed between every two raised strips 3; the filter plate 1 and the raised strips 3 are made of high molecular polyethylene material; the shape of the filter plate 1 can be circular, square or polygonal.

[0011] In a specific application, several filter plates 1 can be placed in series on the horizontal guide shaft by using the connection holes 2 . During the solid-liquid separation and filtration process, the diatomite-injected liquid is pushed by the tube pump system and evenly coated on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com