Gas-solid separation device with dusting brush

A gas-solid separation and dust-removing brush technology, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of poor flow of pyrolysis gas, blockage of biomass particles, trouble in production, etc., to enhance strength, improve Efficiency, avoidance effect of high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the gas-solid separation device with a dust removal brush of the present invention is applied to a biomass rapid pyrolysis liquefaction system. Among them, the biomass rapid pyrolysis liquefaction system generally includes a high-temperature cyclone primary separator and a high-temperature gas-solid separator for separating the remaining solid particles. The gas-solid separation device of the present invention can be used as a high-temperature gas-solid separator of the system.

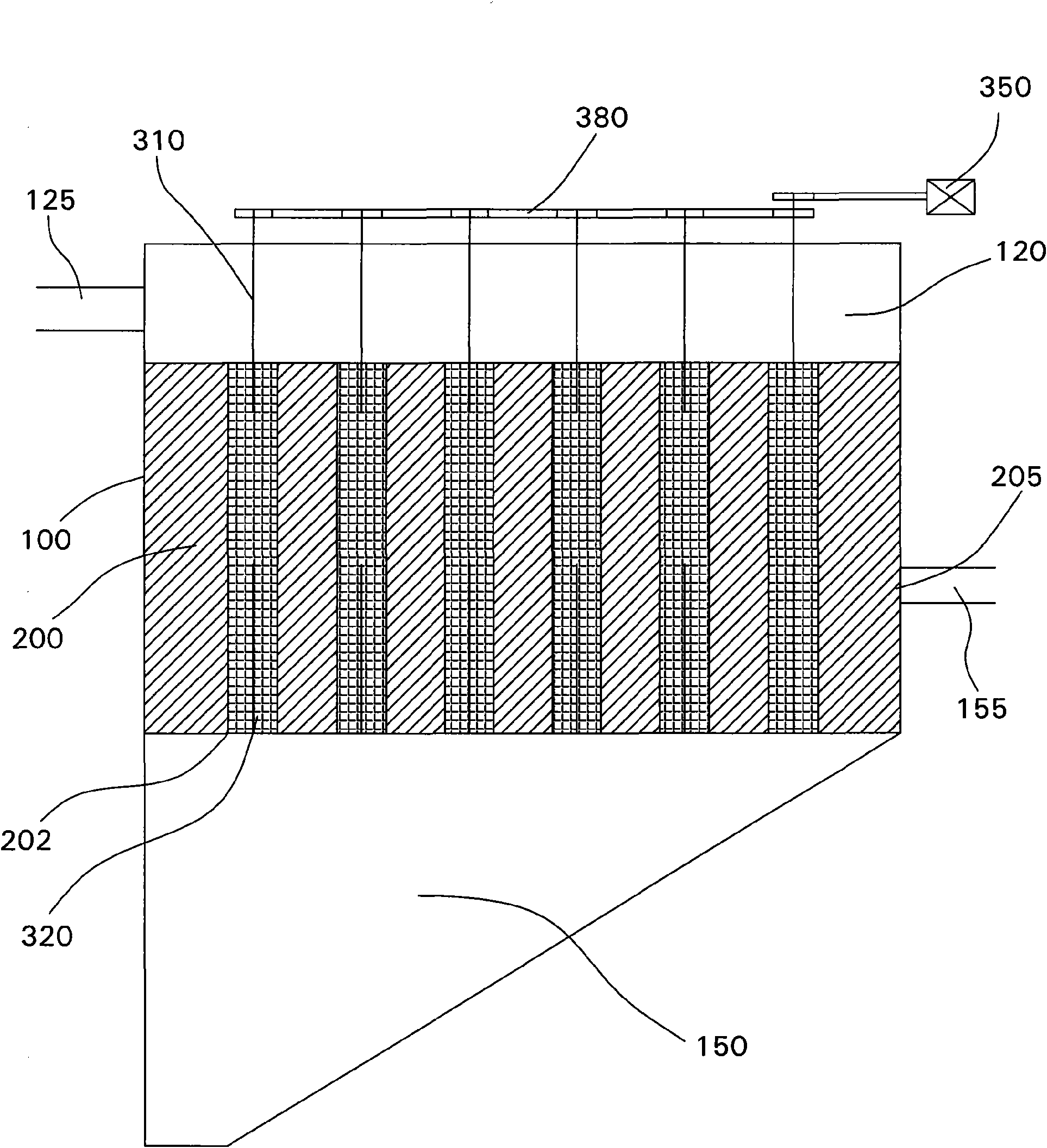

[0031] Please refer to figure 1 The gas-solid separation device of the present invention includes a device body 100 with a processing space inside, a crude gas inlet 125 arranged on one side of the device body 100, a gas outlet 155 arranged on the other side of the device body 100, and a gas outlet 155 formed on the upper part of the processing space. The air inlet chamber 120, the dust collection chamber 150 formed in the lower part of the processing space, the filter elem...

Embodiment 2

[0038] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0039] In this embodiment, the gas-solid separation device of the present invention is applied to an air dust removal and purification system. Moreover, the filter element 200 is provided with ten through holes 202 connecting the air intake chamber 120 and the dust collection chamber 150 , and the dust removal system is provided with ten dust removal brushes 320 correspondingly.

[0040] The dust removal system is provided with a pressure sensor (not shown) for sensing changes in the gas state, and a controller (not shown) for controlling the startup or shutdown of the dust removal system according to the information obtained from the pressure sensor. The pressure sensor is set in the processing space. When the filter element is blocked, the pressure in the processing space will become higher. The controller can compare the obtained information with the ...

Embodiment 3

[0043] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0044] The dust removal system is provided with a timing controller (not shown) for timing opening and closing of the dust removal system, so that the dust removal system is automatically opened after a certain time interval and automatically closed after a certain period of time.

[0045] The dust removal system also includes a pulse device (not shown) for making the dust removal brush 320 rotate forward and reverse at intervals.

[0046] The driving part 350 includes three motors, each of which drives a pair of dust removal brushes 320 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com