Gas-solid separation device with backblow system

A gas-solid separation and crude gas technology, applied in separation methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of biomass particle blockage, poor pyrolysis gas flow, yield loss, etc., and achieve the goal of reducing energy The effects of consumption, avoidance of difficulties, and cost savings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

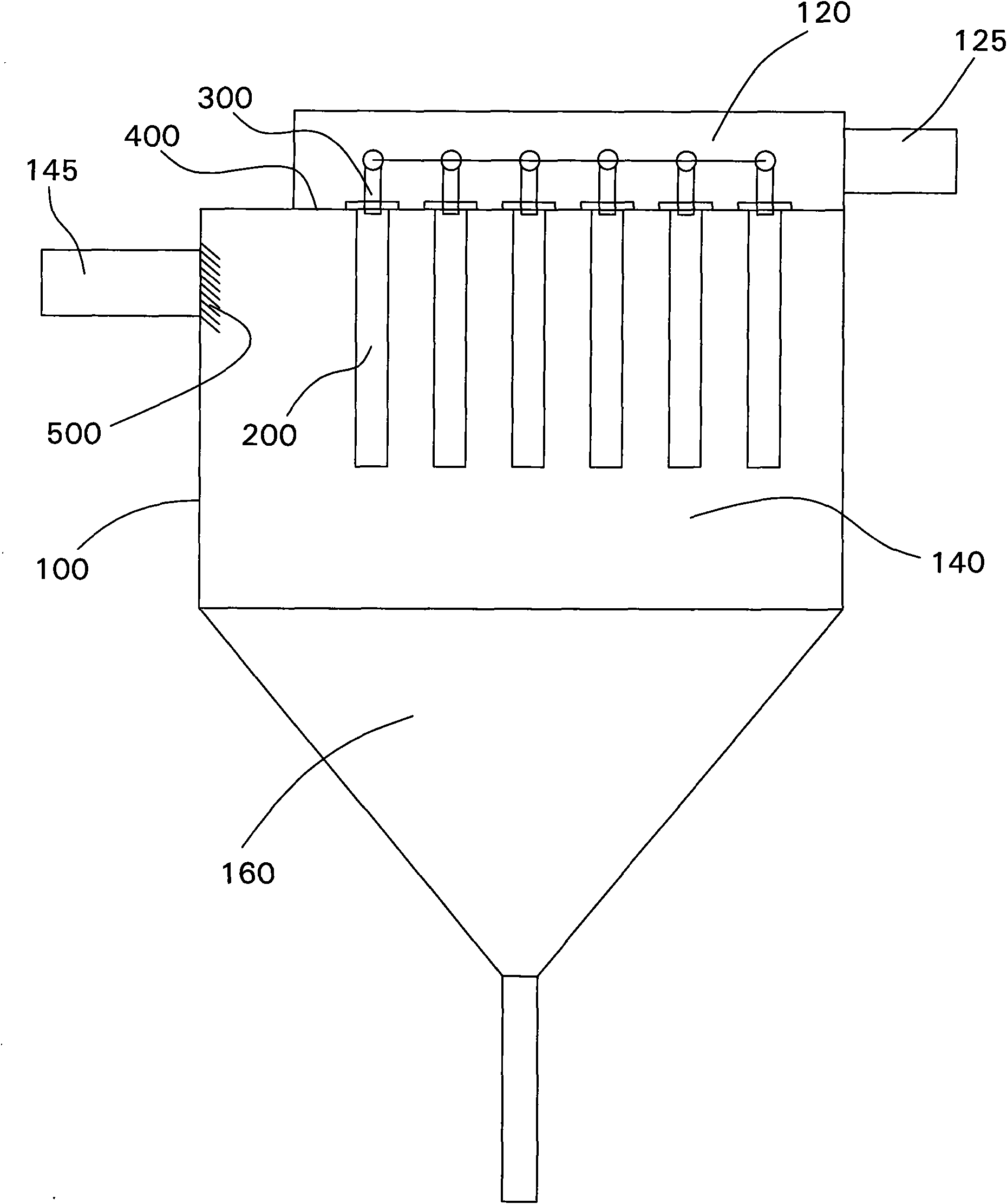

[0029]In this embodiment, the gas-solid separation device with a backflushing system of the present invention is applied to a biomass rapid pyrolysis liquefaction system. Among them, the biomass rapid pyrolysis liquefaction system generally includes a high-temperature cyclone primary separator and a high-temperature gas-solid separator for separating the remaining solid particles. The gas-solid separation device of the present invention can be used as a high-temperature gas-solid separator of the system.

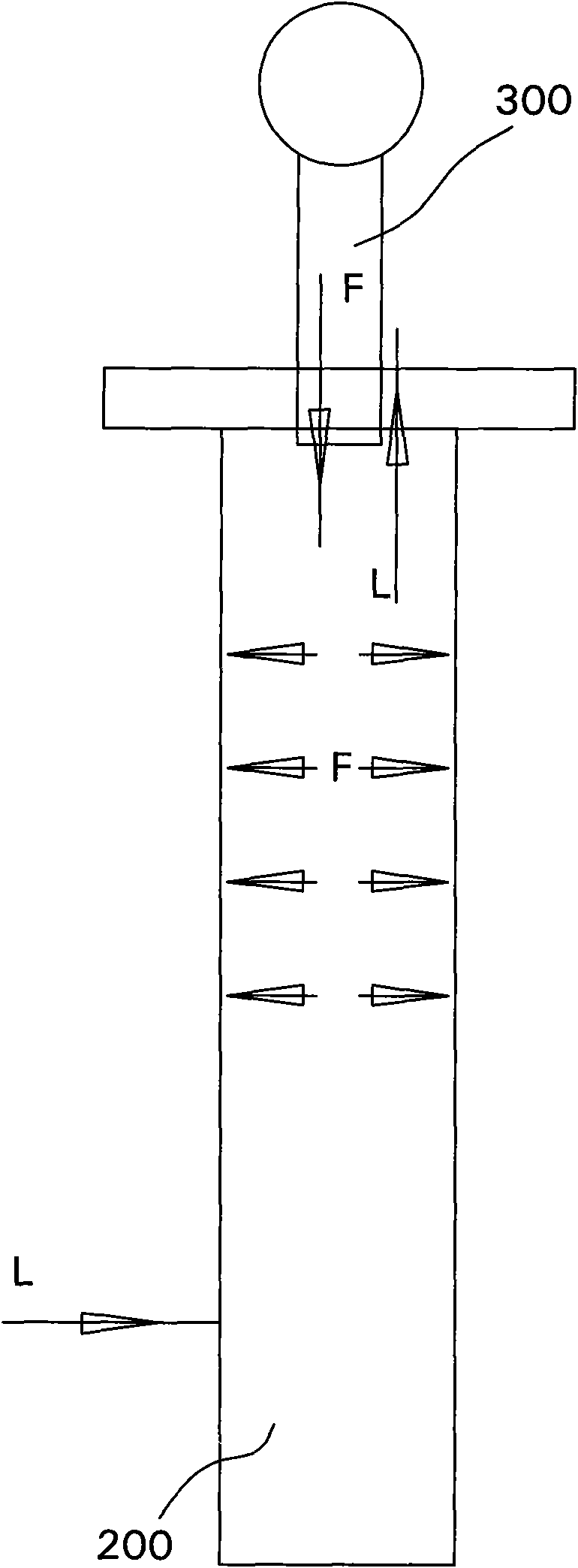

[0030] Please refer to figure 1 and figure 2 The gas-solid separation device of the present invention includes a device body 100 with a processing space inside, a crude gas inlet 145 disposed on one side of the device body 100, a gas outlet 125 disposed on the other side of the device body 100, and a gas outlet 125 disposed in the processing space. And the processing space is divided into the partition plate 400 of the filter chamber 140 and the clean gas chamber 120, the...

Embodiment 2

[0035] As another kind of scheme of the present invention, other parts are identical with embodiment 1, and difference is:

[0036] In this embodiment, the gas-solid separation device of the present invention is applied to an air dust removal and purification system. In addition, the gas-solid separation device is provided with three filter elements 200 at intervals, and the blowback system includes three blowback ports 300 correspondingly arranged on the top of each filter element 200 .

[0037] Among them, the back blowing system is provided with a timing controller for timing opening and closing of the back blowing system, so that the back blowing system is automatically opened after a certain time interval and automatically closed after a certain period of time.

[0038] In addition, the blowback system can control each blowback port 300 to work independently.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com