Die-casting die casting system for magnesium alloy automobile engine cylinder head casing

A technology of automobile engine and pouring system, which is applied in the direction of cylinder head, engine components, machine/engine, etc. It can solve the problems of difficult to guarantee the quality of die casting parts, waste of raw material energy consumption, high cost loss, etc., to reduce energy consumption of enterprises, filling Smooth and reduce the effect of shrinkage and porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

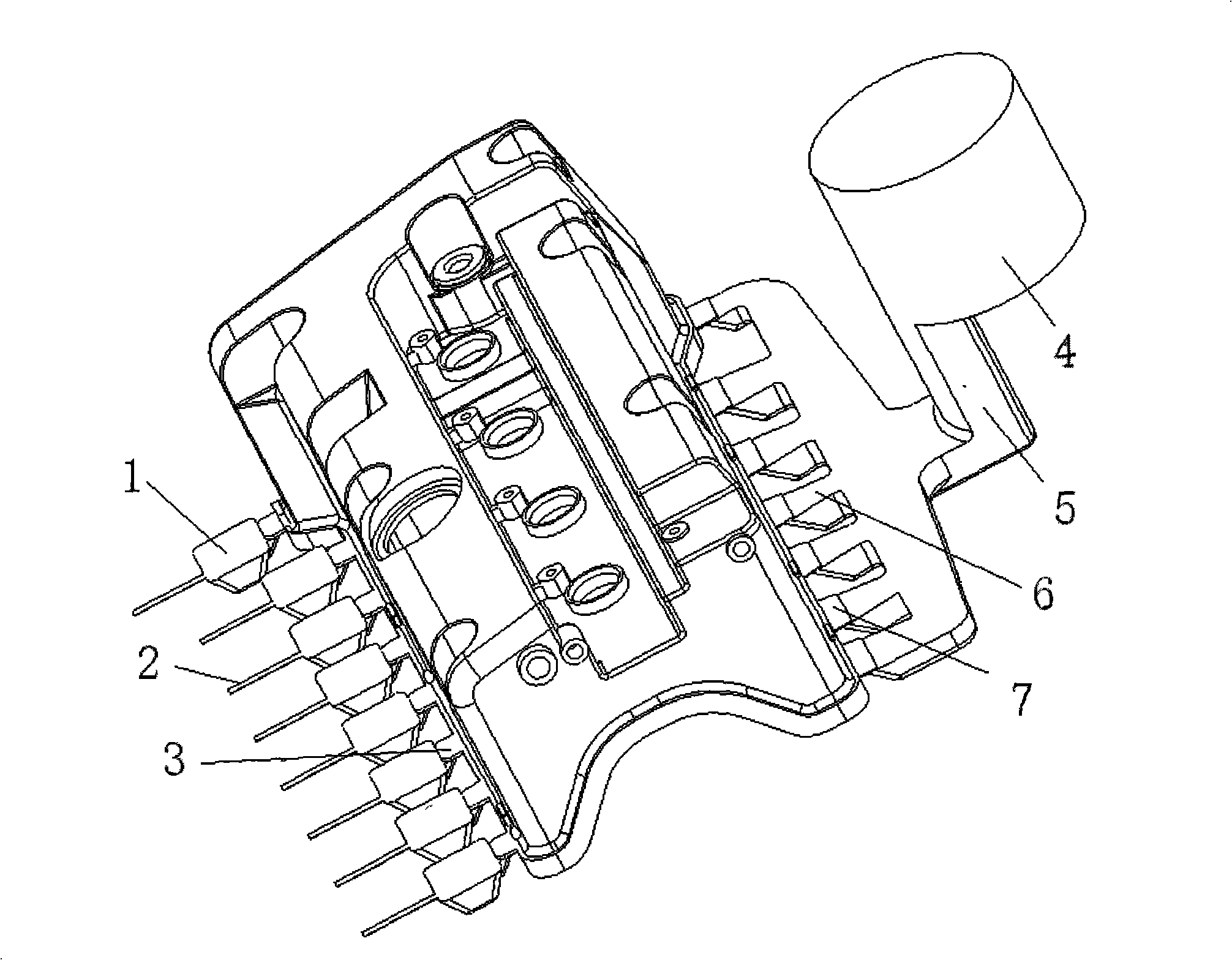

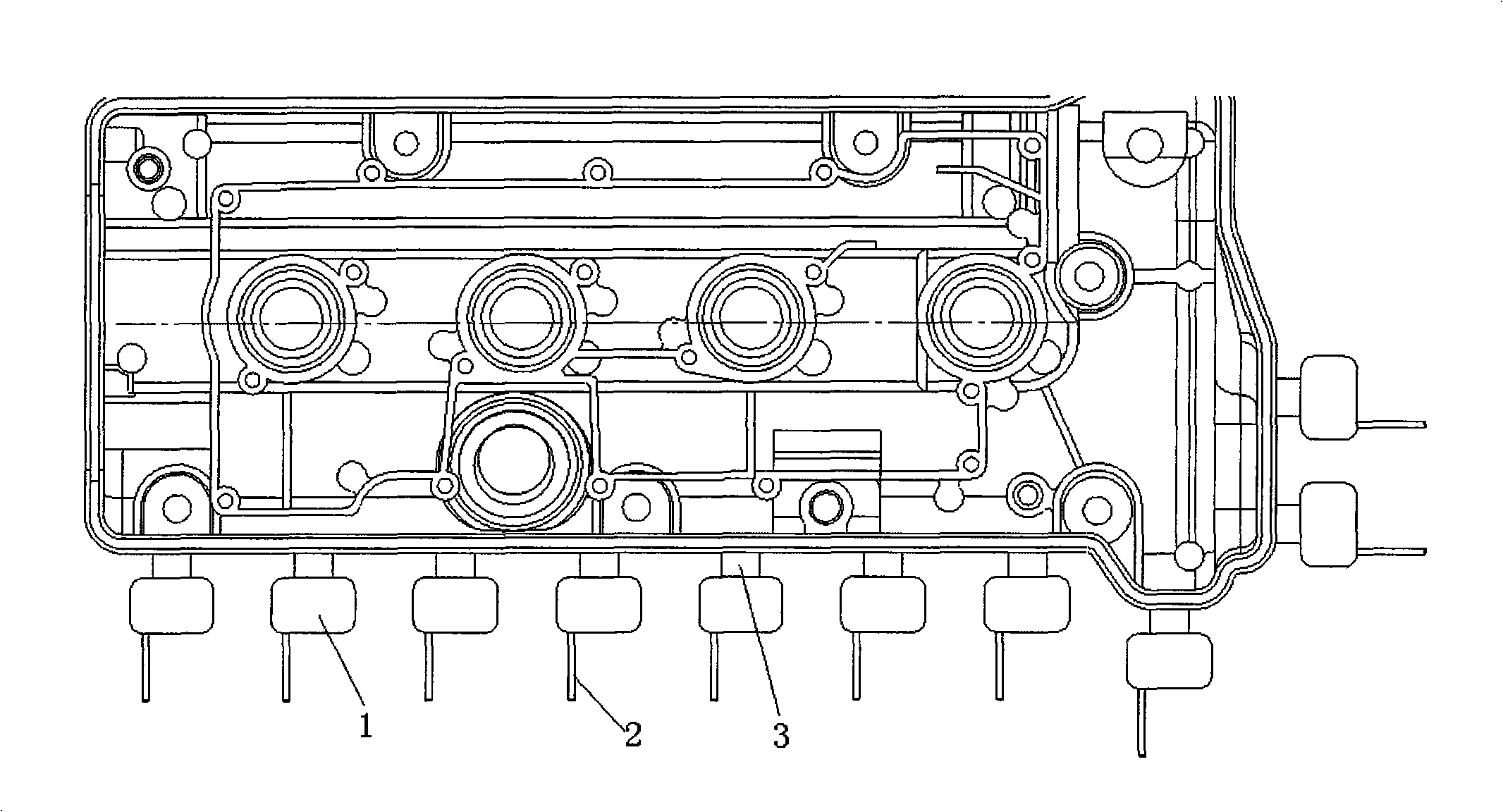

[0011] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

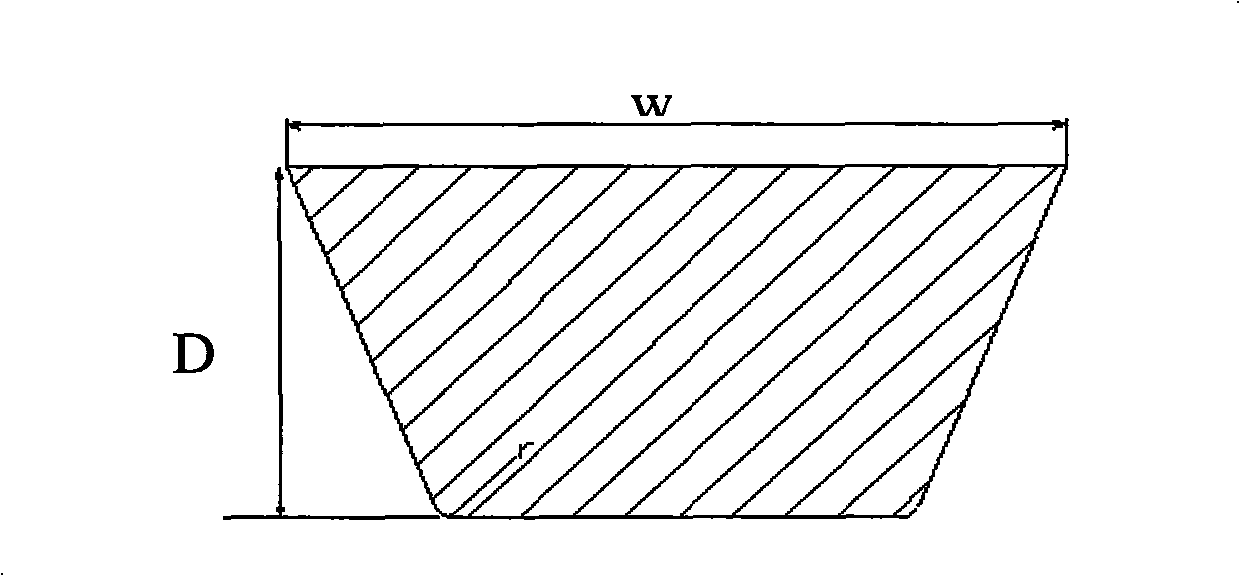

[0012] The present invention mainly aims at defects such as shrinkage cavity, air hole and cold shut in the original gating system during the die-casting molding process, improves its structure on the basis of the original gating system, and conducts a reasonable design and layout of the overflow system, And use the special numerical simulation software JSCAST for casting to simulate the velocity field and temperature field of the filling process, so as to optimize the size of the runner and overflow system of the gating system. The optimized gating system has laid the foundation for ensuring the quality of die castings. At the same time, the total volume of the optimized castings is reduced by 6.9% compared with the original one, which is of practical significance for enterprises to reduce energy consumption and save costs.

[0013] This emb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com