Multi-component small powder automatic packaging palletizing method

An automatic packaging and multi-component technology, applied in packaging, transportation packaging, transportation and packaging, etc., to save manpower, easy to use on site, and realize the effect of fully automatic control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

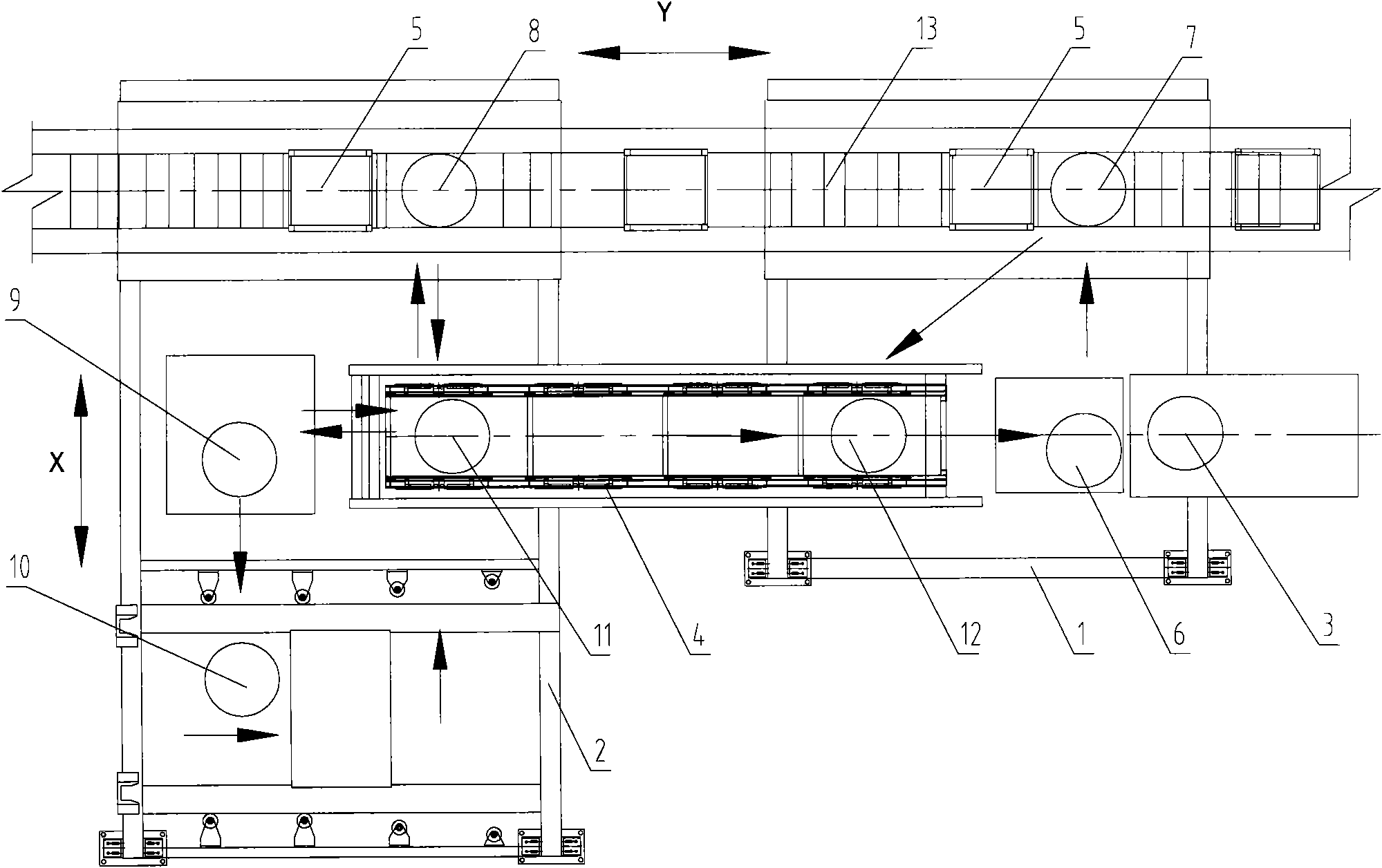

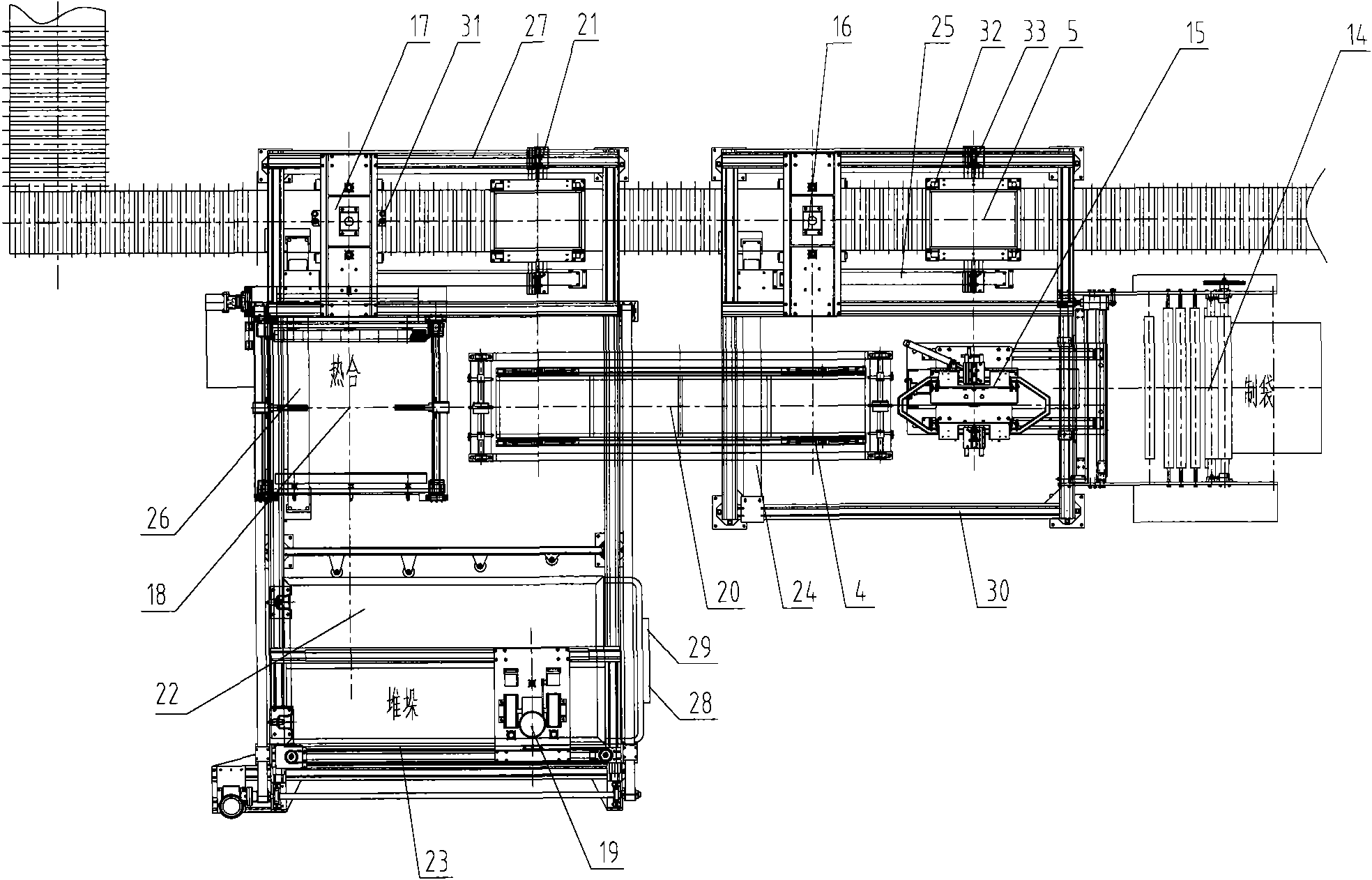

[0019] Such as figure 1 As shown, 1 is the equipment for putting plastic bags, and 2 is the equipment for taking heavy material bags. figure 1 Each arrow direction in represents the moving direction of each station device.

[0020] The workflow of the method of automatic packaging and stacking of multi-component small materials:

[0021] (1) Working process of the bagging station: put the plastic film coil on the bag making station 3 of the bag making machine 14; make a plastic bag suitable for the requirements; send it to the bag opening station 6; pass the bag The bag opening device 15 opens the mouth of the plastic bag for standby; the bag releasing manipulator 16 grabs the material bag clamping device 4 from the clamper station 12 on the material bag clamping device transmission device 20, and then the bag releasing manipulator Y Drive the bag releasing manipulator 16 to the driving mechanism 25 to reach the bag opening station 6; the bag clamp on the bag releasing manip...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com