Principle and novel method for preparing orientation-controllable electrostatic spinning nano polymer fibers

An electrospinning and nanofiber technology, applied in fiber processing, conjugated synthetic polymer rayon, single-component synthetic polymer rayon, etc., can solve the weaving method to manufacture various textiles and limit polymer nanofibers Industrial application and other issues, to achieve the effect of easy promotion and application, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] A: N,N-dimethylformamide solution prepared as polyacrylocyanide with a concentration of 8% by weight, and magnetically stirred at 50° C. for 2 hours;

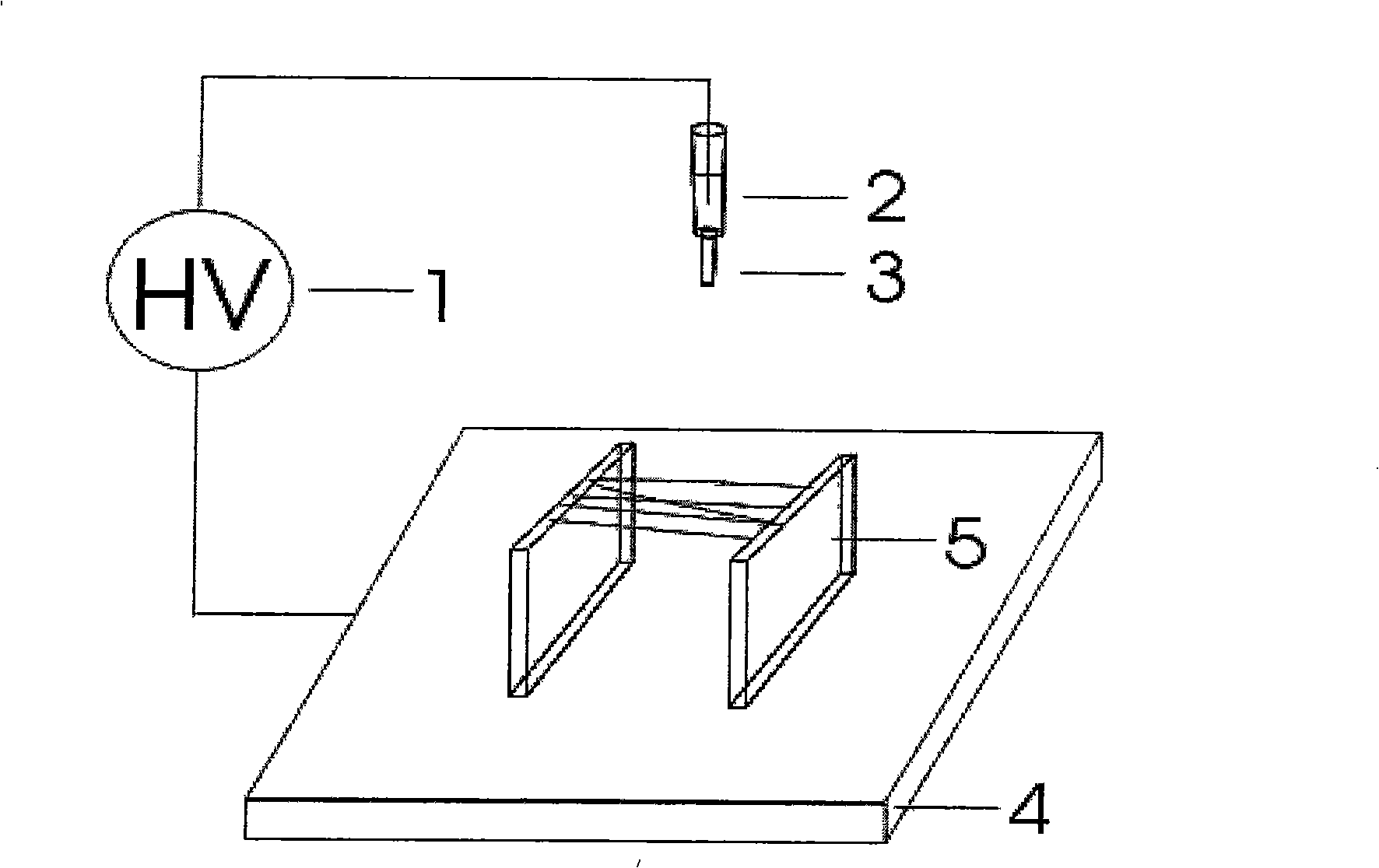

[0032] B: Add the above solution into the syringe 2, the inner diameter of the metal nozzle 3 of the syringe 2 is 0.5mm, and the metal nozzle 3 is connected to the positive pole of the DC high-voltage power generator; aluminum foil is used as the metal cathode collecting plate 4, and the distance between the metal cathode collecting plate 4 The distance between the metal nozzles 3 is 10cm; a pair of collector plates 5 arranged in parallel are placed on the metal cathode collector plate 4, and the distance between the two collector plates 5 is 5cm. The material of the collector plates 5 is a glass tank, and the tank is filled with There is a glacial acetic acid solution, and the dielectric constant of the glacial acetic acid solution is 4.1; a voltage of 9kV is applied for electrospinning.

Embodiment 2

[0034] A: N, N-dimethylformamide solution of polymethyl methacrylate with a concentration of 8% by weight was prepared, and magnetically stirred at 50° C. for 2 hours;

[0035] B: Add the above solution into the syringe 2, the inner diameter of the metal nozzle 3 of the syringe 2 is 0.5mm, and the metal nozzle 3 is connected to the positive pole of the DC high-voltage power generator; aluminum foil is used as the metal cathode collecting plate 4, and the distance between the metal cathode collecting plate 4 The distance of the metal sprinkler 3 is 10cm; a pair of collector plates 5 arranged in parallel are placed on the metal cathode collector plate 4, and the distance between the two collector plates 5 is 5cm. The material of the collector plates 5 is iron oxide, and its dielectric The constant is 12;

[0036] Electrospinning was performed by applying a voltage of 6.5 kV.

Embodiment 3

[0038] A: N,N-dimethylformamide solution prepared as polyacrylocyanide with a concentration of 8% by weight, and magnetically stirred at 50° C. for 2 hours;

[0039] B: Add the above solution into the syringe 2, the inner diameter of the metal nozzle 3 of the syringe 2 is 0.5mm, and the metal nozzle 3 is connected to the positive pole of the DC high-voltage power generator; aluminum foil is used as the metal cathode collecting plate 4, and the distance between the metal cathode collecting plate 4 The distance between the metal nozzles 3 is 10cm; a pair of collector plates 5 arranged in parallel are placed on the metal cathode collector plate 4, and the distance between the two collector plates 5 is 5cm. The material of the collector plates 5 is a glass tank, and the tank is filled with There is a methanol solution, and the dielectric constant of the methanol solution is 25; a voltage of 9kV is applied for electrospinning.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com