Differential trajectory jet energy dissipater in absorption basin

A differential type, stilling pool technology, applied in water conservancy projects, marine engineering, coastline protection and other directions, can solve the problems of hydraulic jump formation, cavitation damage, large space occupation, etc., to increase the single-wide flow range, The effect of strong anti-cavitation ability and project cost saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

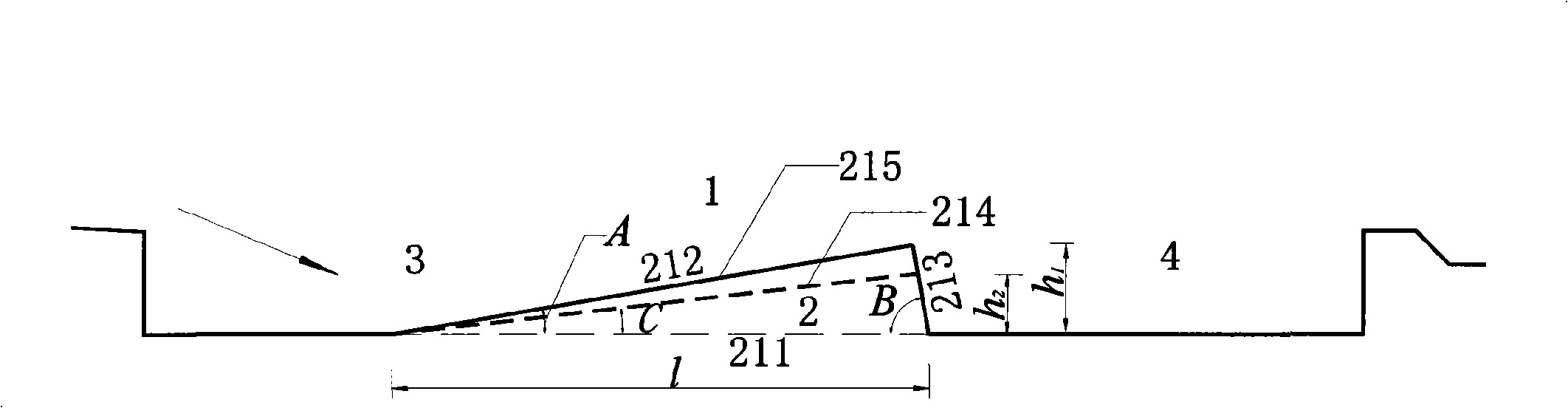

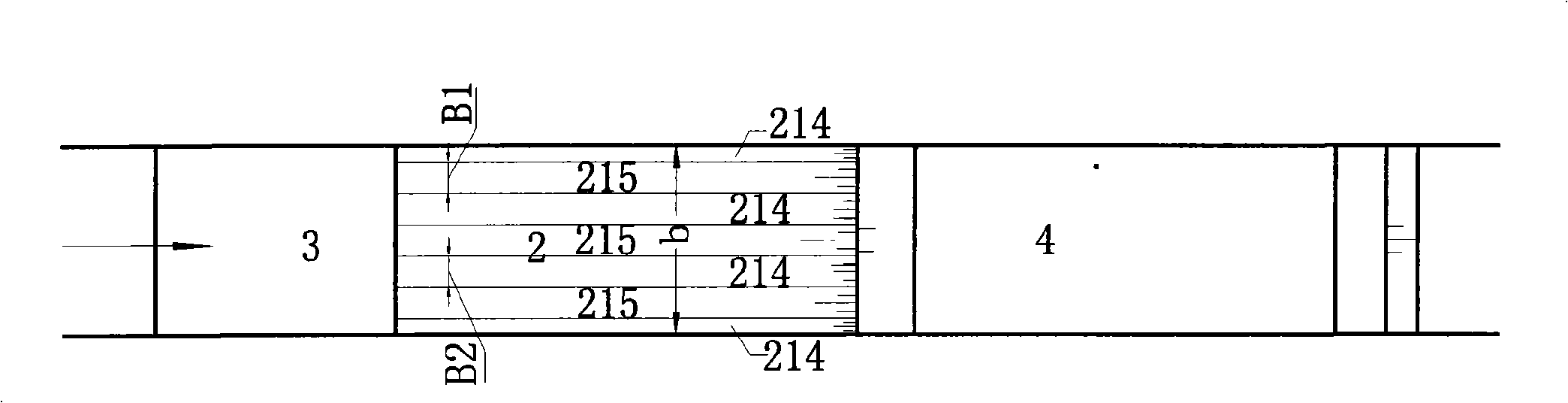

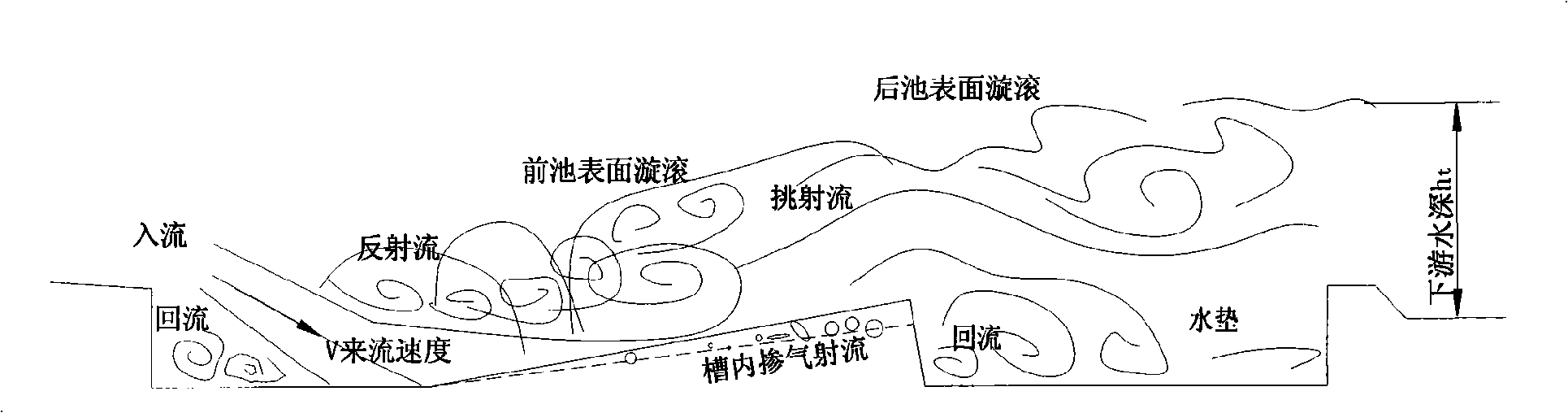

[0035] Figure 4 It is an example diagram of a combination of a stepped auxiliary energy dissipator and a differential triangular deflector sill energy dissipator in a conventional stilling basin in the optimization hydraulic model test of a certain engineering spillway exit stilling basin. The structure of the example is: the stilling basin 1 and the differential triangular ridge 2 are manufactured as a continuous whole. The differential triangular sill divides the stilling pool into two parts, the front pool 3 and the rear pool 4. The differential triangular sill is 25m in length along the water flow direction; The width is the same, 30m, and the lifting position is 25m away from the entrance of the stilling basin, which is about 1 / 3 of the length of the stilling basin; there are 4 deflecting troughs and 3 main deflecting sills in the differential triangular sill. Launders and main sills are symmetrically crossed left and right. The widths of the three main sills are all 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com