Full-sealing casement plastic-steel window

A plastic-steel window, full-sealing technology, applied in the direction of sealing device, parallel glass structure, wing fan arrangement, etc., can solve the problems of large heat dissipation, reduced profile section, poor sealing performance of plastic-steel windows, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

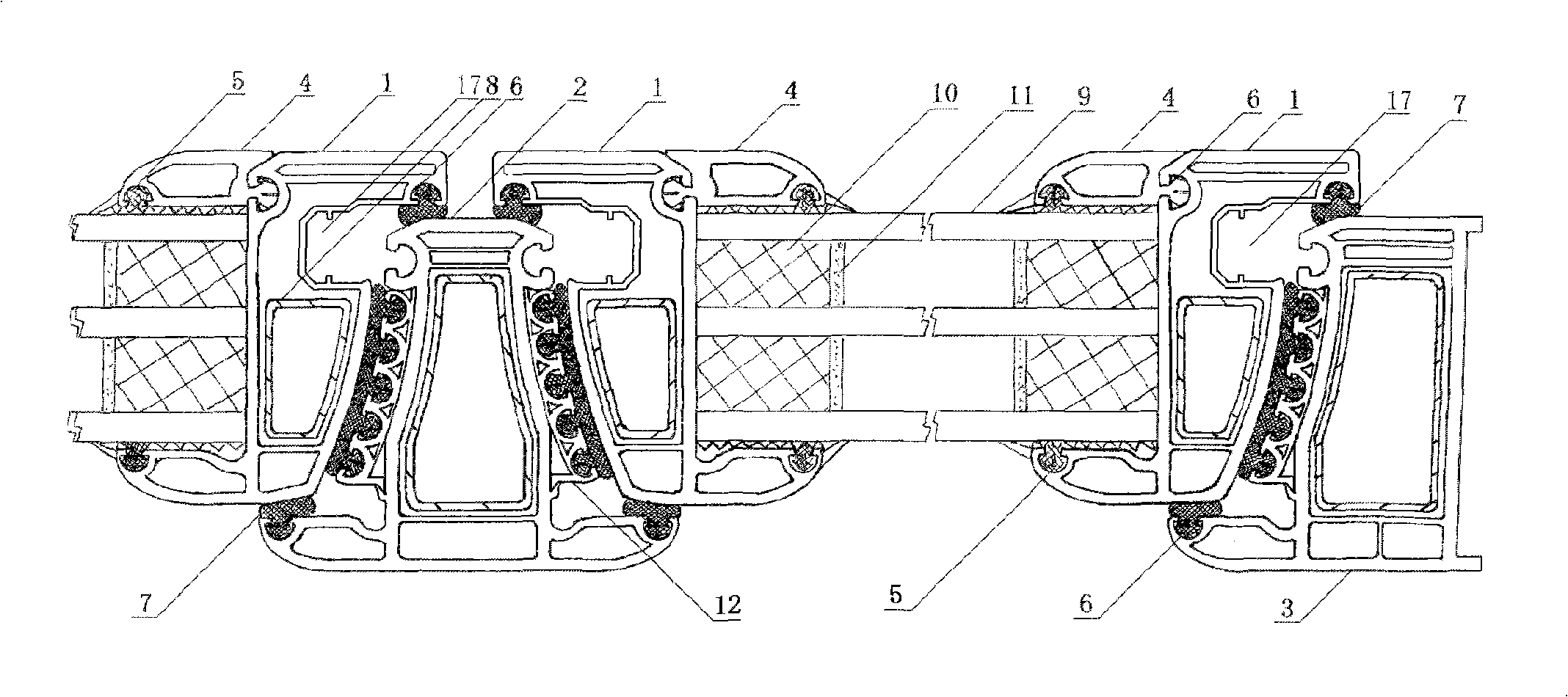

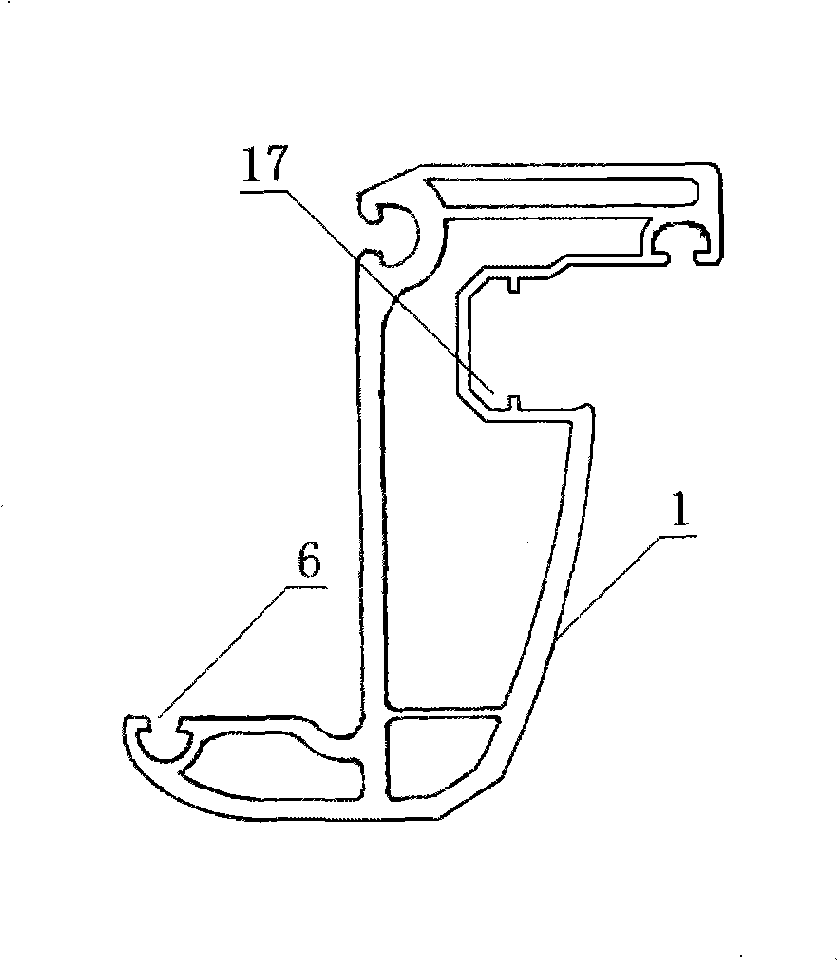

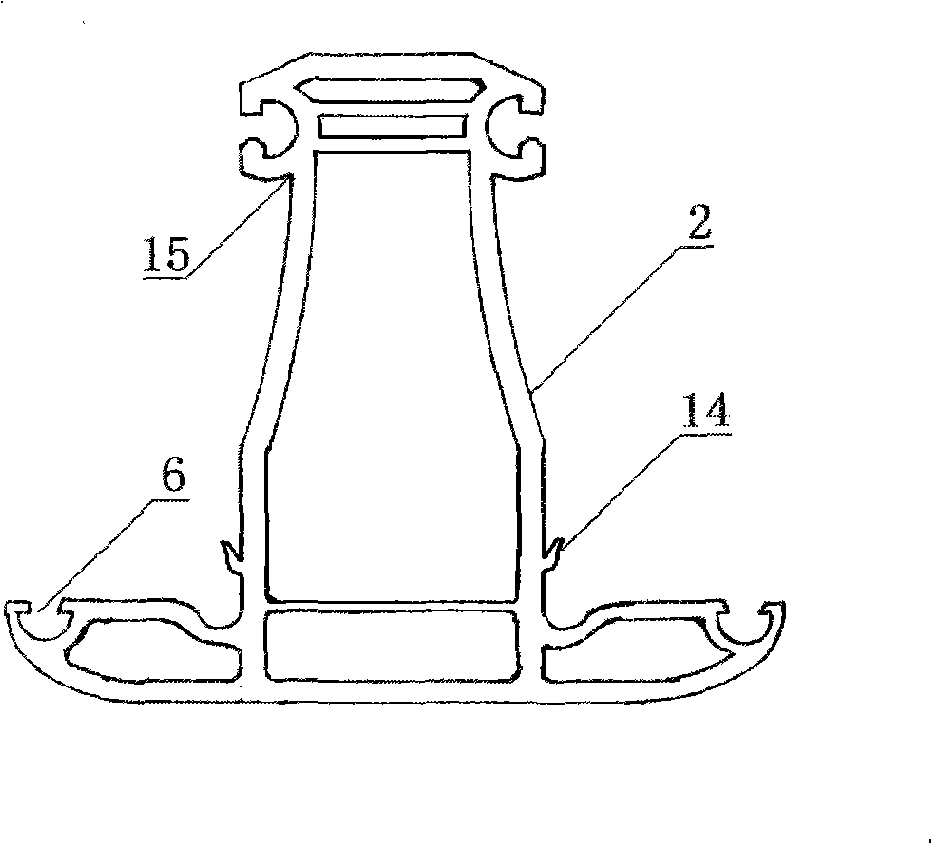

[0009] Combine below figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 The fully sealed casement plastic-steel window of the present invention is further described, which includes glass 9, glass bead 4, sealant strip 7, fan material 1, stile material 2 and frame material 3, and glass 9 passes through glass sealant strip 5 and glass bead 4 Withholding and fixing, the non-visible surface of fan material 1 is composed of convex arc surface, U-shaped groove 17 and inclined surface, the invisible surface of stiff material 2 and frame material 3 is composed of concave arc surface, plane and inclined surface, fan material 1 The non-visible surface is overlapped with the non-visible surface of the jig material 2 or the frame material 3 through the sealing rubber strip support 12, and cooperates with the bevel surface of the jig material 2 or the frame material 3. After the frame fan is closed, it is sealed by the sealing rubber strip 7 is divided into two independent chamb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com