Processing method of waste acid dripping sludge

A treatment method and technology of acid mud, applied in the direction of lead-acid battery electrodes, etc., can solve the problems of waste of treatment methods, increase of enterprise cost, etc., and achieve the effect of improving service life, reducing enterprise cost and prolonging cycle service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

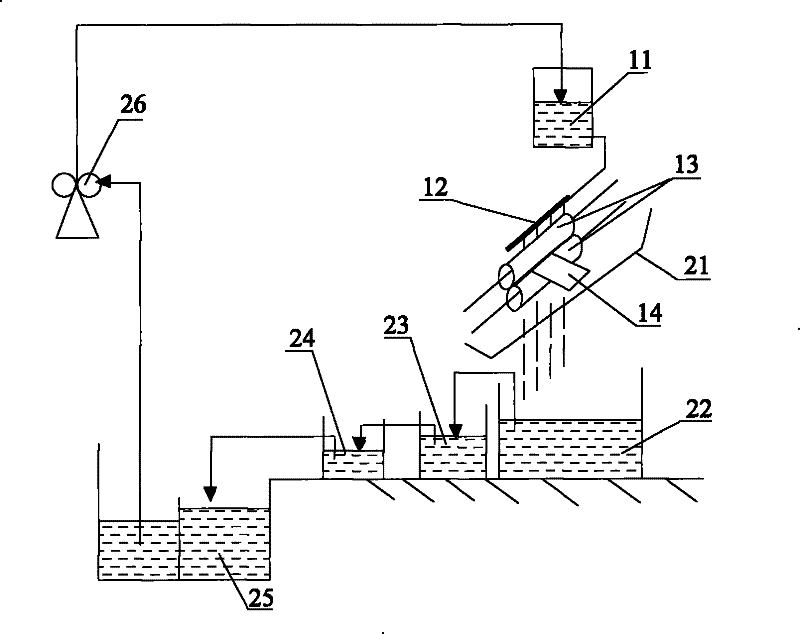

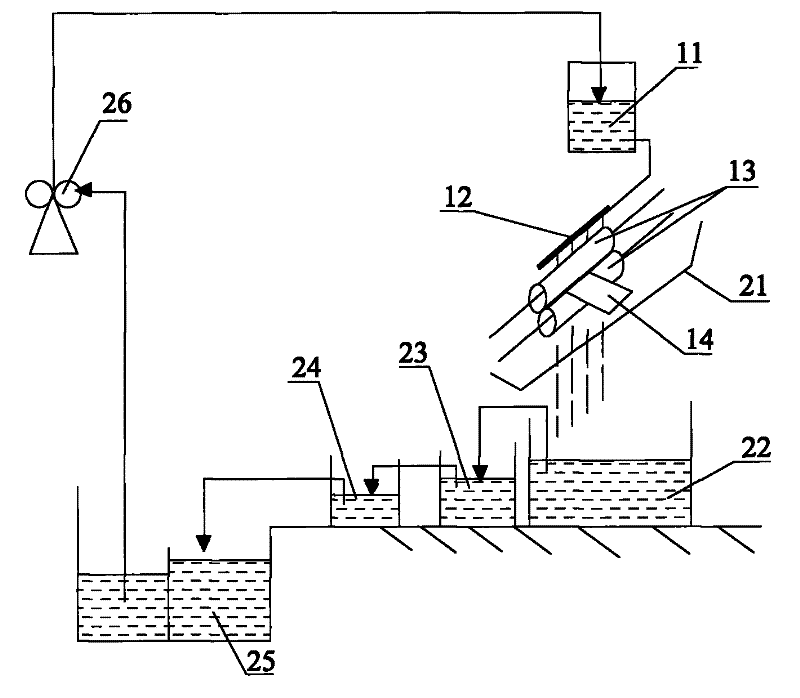

[0048] according to figure 1 In the acid leaching device and precipitation device shown, the waste acid mud produced in the acid leaching process is subjected to primary precipitation, secondary precipitation, tertiary precipitation, and quaternary precipitation in sequence, and dilute sulfuric acid obtained through quaternary precipitation is injected into the storage tank. Continue to carry out the acid leaching step in the acid tank;

[0049] Dry the precipitates obtained in the primary precipitation, secondary precipitation, tertiary precipitation and quaternary precipitation to obtain large particles of PbSO 4 ;

[0050] Prepare lead oxide powder with a degree of oxidation of 85wt% and the large particles of PbSO 4 mixed, the lead oxide powder was mixed with PbSO 4 The molar ratio is 4:1;

[0051] The mixed lead oxide powder and PbSO 4 Grind in a Raymond machine for 3 to 4 hours;

[0052] The ground obtained in 4PbO · PbSO 4 Mixed with lead oxide powder with an oxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com