Camera chip size module with novel structure and method for producing same

A technology with a chip size and a new structure, applied in the field of electron optics, can solve the problems of printed circuit board size inconsistency, waste of data and inventory, bulky volume, etc., and achieve the effect of convenient and flexible assembly operation, precise focal length, and small size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail with preferred embodiment:

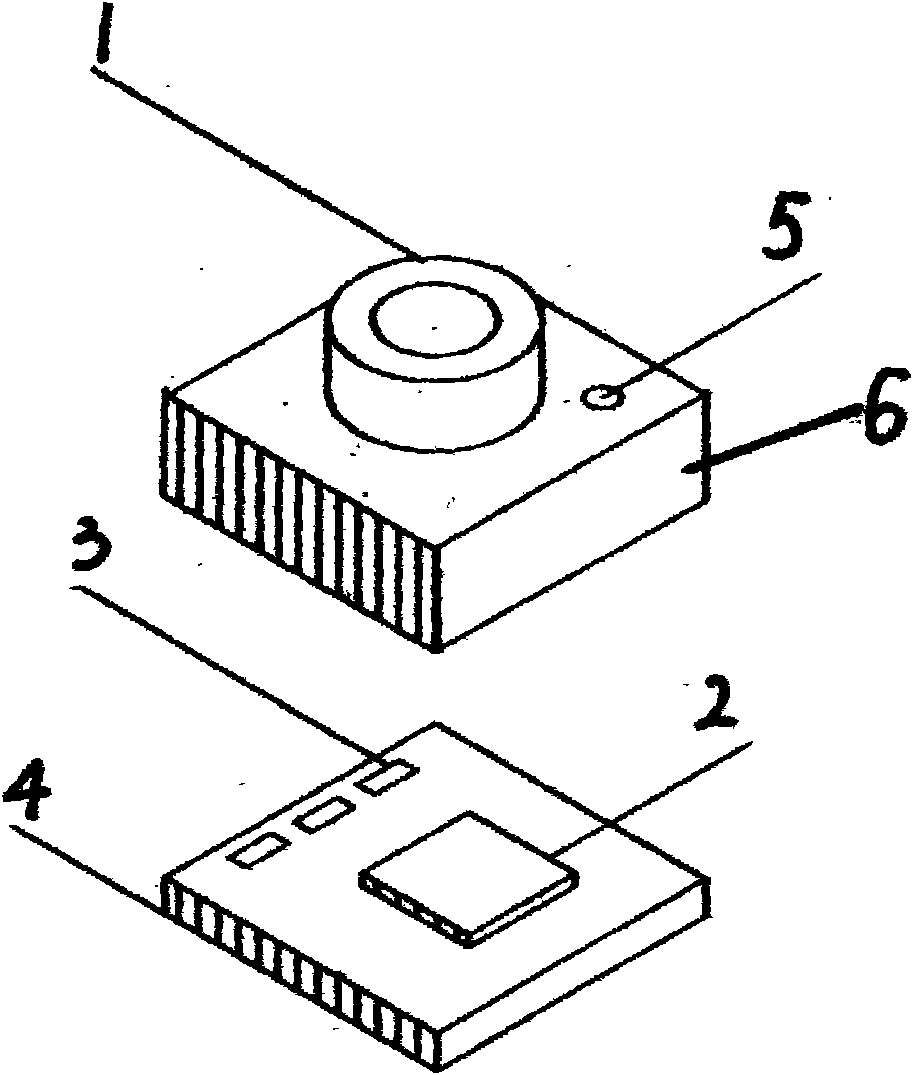

[0018] The present invention consists of a lens (1), a sensor (2), components (3), a circuit board (4) and an exhaust hole (5). The circuit board (4) and components (3) are ultra-miniature designs, and A sensor (2) is provided in the middle of the surface of the board (4), components (3) are provided at the edge, an air vent (5) is provided on the lens base (6), the size of the circuit board (4) is equal to the size of the chip package, and the circuit board (4) is The board (4), the sensor (2) and the components (3) are ultra-precisely assembled inside the lens base (6).

[0019] Production method of the present invention is:

[0020] 1. The use of high-temperature materials (Reflowable) solves the problem of fine dust generated by the assembly process. Its high-temperature material technologies include:

[0021] a. Glass molded lens repla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com