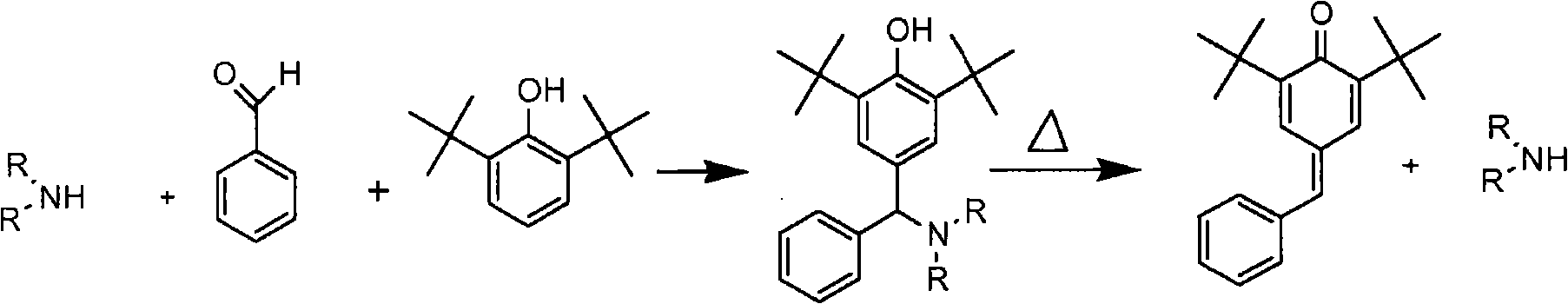

Process for the production of quinone methide

A technology of quinone methide and benzylidene, applied in the field of 4-benzylidene-2, which can solve the problems of increasing raw material cost and processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment I

[0023] To a 500 ml RB flask equipped with a Dean Stark (connected to a water-cooled reflux condenser) was added 51.3 g of 2,6-di-tert-butylphenol, 26.5 g of benzaldehyde and 46 g of N,N- Di-n-propyl-amine. The mixture was heated at 130° C. for 9.5 hours in an oil bath placed on a magnet under a nitrogen atmosphere with stirring. Afterwards, the reaction mixture was distilled under vacuum at 114° C. for 4 hours. The initial vacuum was 250mmHg for 2-3 hours. Afterwards, the vacuum was slowly reduced to 10 mmHg and maintained at this value until the end of the reaction. The weight of the final product was 73.2 g, and the weight of the distillate after separation of the water was 44 g. The content of quinone methide in the product is 84.79%.

Embodiment II

[0025] Into a 500ml RB flask was added 26.5g benzaldehyde and 32.3g N,N-di-n-butylamine. The mixture was maintained at 70°C for 30 minutes. Afterwards, 51.5 g of 2,6-di-tert-butyl-phenol were added, and the mixture was maintained at 115-118° C. for 30 hours. To recover the amine, the reaction mixture was distilled at 130° C. under 30 mmHg vacuum for 5 hours, after removal of N,N-di-n-butylamine by distillation, 69.78% of quinone methides were found in the product.

Embodiment III

[0027]Into a 500ml RB flask was added 21.4g benzaldehyde and 41.2g N,N-di-n-butylamine, and 26g 2,6-di-tert-butyl-phenol was added. The mixture was maintained at 110°C for 12 hours. Afterwards, the reaction mixture was subjected to amine distillation at 110° C. at 30 mmHg for 1.5 hours. The vacuum was slowly reduced to 6 mmHg, and distillation was continued for an additional 2.0 hours. After distillation of N,N-di-n-butyl-amine, the final product in the reaction flask was shown to have 63.82% quinone methides.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com