Methods for producing glucosamine from microbial biomass

A kind of technology of glucosamine and microbial biomass, applied in the production field of glucosamine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

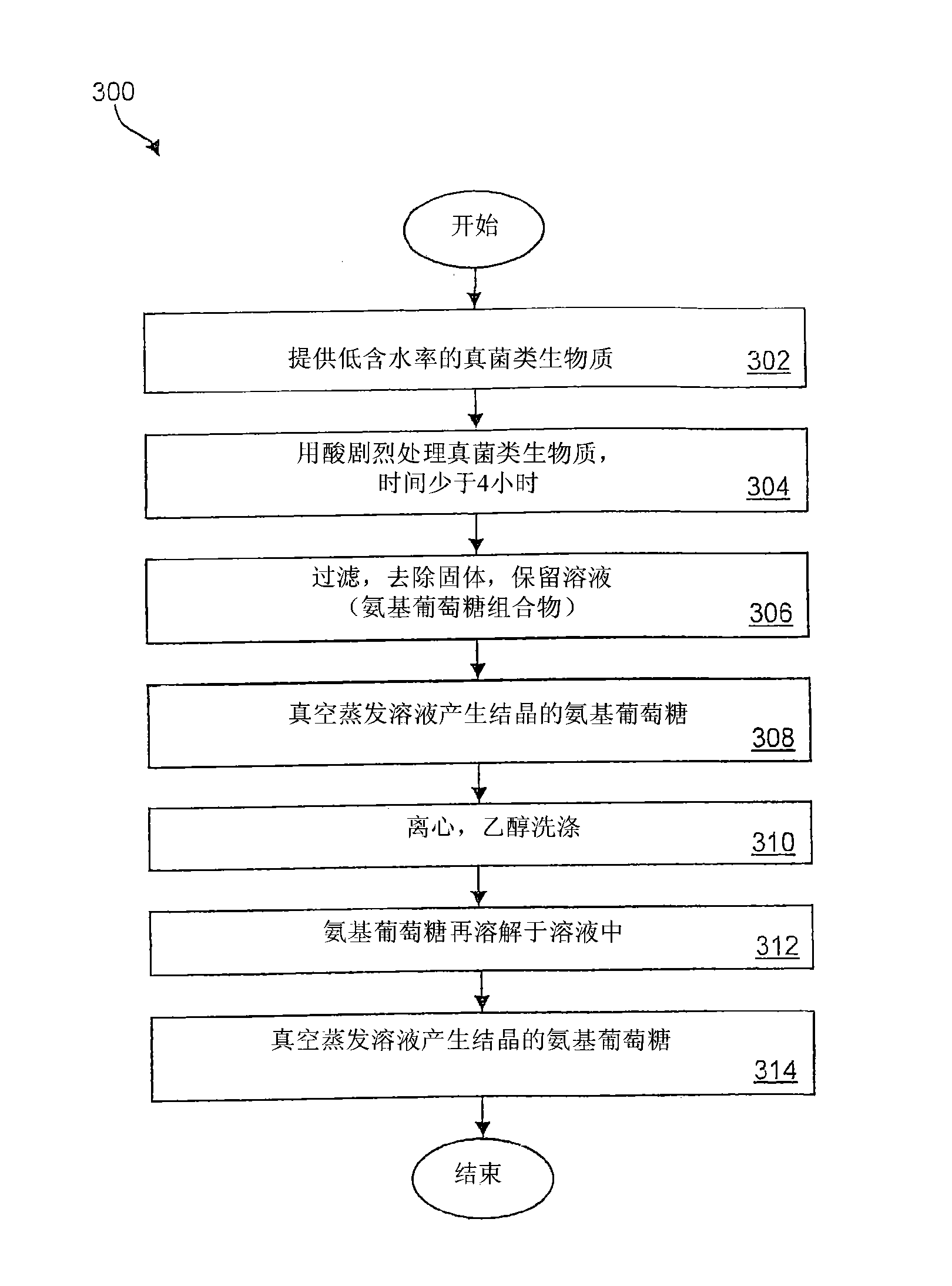

[0043] 100 g of dried citric acid biomass was mixed with 250 ml of 20% hydrochloric acid, and the mixture was heated to reflux at three different temperatures in three experiments: 60 °C, 80 °C and 100 °C. Samples were taken at different intervals, and the reaction was analyzed by high-performance liquid chromatography. The chromatograph model was "Agilent 1100" of Agilent Company. See the reaction result Figure 4 , which shows the production of glucosamine as a function of reaction time and temperature. As shown, starting with 100 grams of dry biomass (which contains about 10 grams of chitin), the reaction produced about 6 grams of glucosamine. Thus, relative to the starting 100 grams of dry biomass, the yield was 6%; relative to 10 grams of chitin in the dry biomass, the yield was 60%.

[0044] It can be seen from the figure that the yield of glucosamine obtained by the reaction at 80°C and 100°C is higher than that at 60°C. It is obvious that the yield of glucosamine in...

Embodiment 2

[0048] 100 g of dry citric acid biomass was mixed with 300 ml of 31% hydrochloric acid, and the mixture was heated to reflux at 100° C. for 2.5 hours. After the reaction, filter and evaporate the filtrate to about 15-30 ml. About 50 ml of ethanol was added to this solution, and the mixture was vortexed to accelerate the precipitation of glucosamine. Then, the precipitated glucosamine was filtered from the solution and washed with ethanol. Dissolve the precipitated glucosamine in water and recrystallize with an evaporator. The purity of glucosamine in the final product is greater than 98%.

Embodiment 3

[0050] 100 grams of dried mushrooms were mixed with 300 milliliters of 31% hydrochloric acid, and the mixture was heated to reflux at 100° C. for 2.5 hours. After the reaction was complete, the mixture was filtered and the filtrate was evaporated to about 15-30 ml. About 50 ml of ethanol was added to this solution, and the mixture was vortexed to accelerate the precipitation of glucosamine. Then, the precipitated glucosamine was filtered from the solution and washed with ethanol. Dissolve the precipitated glucosamine in water and recrystallize with an evaporator. The purity of glucosamine in the final product is greater than 98%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| Ash content | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com