Automatic cutting machine for outer curled edges of polyethylene pipes

A cutting machine, polyethylene technology, applied in metal processing and other directions, can solve the problems of unguaranteed cutting quality, residual curling, uneven cutting curling, etc., to improve cutting quality, improve work efficiency, and fast cutting speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Referring to the accompanying drawings, the present invention will be described in detail below.

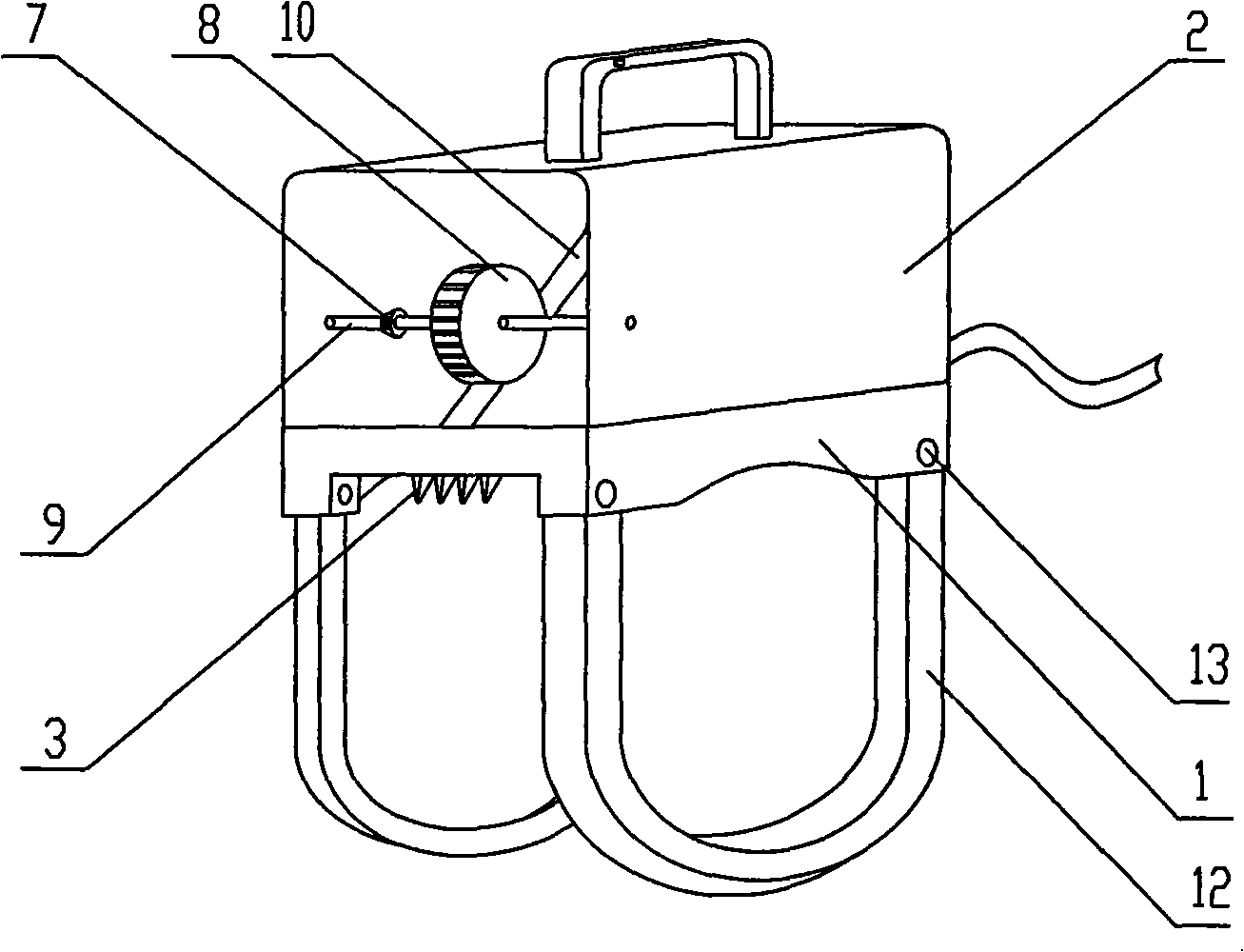

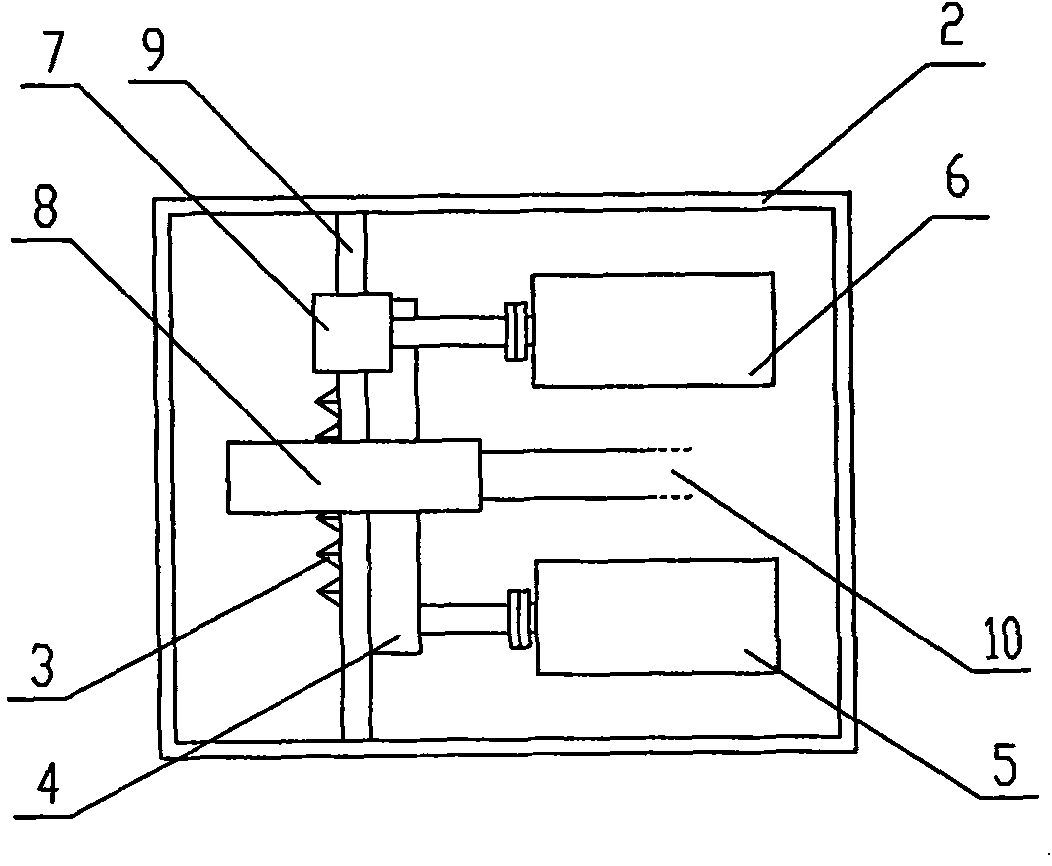

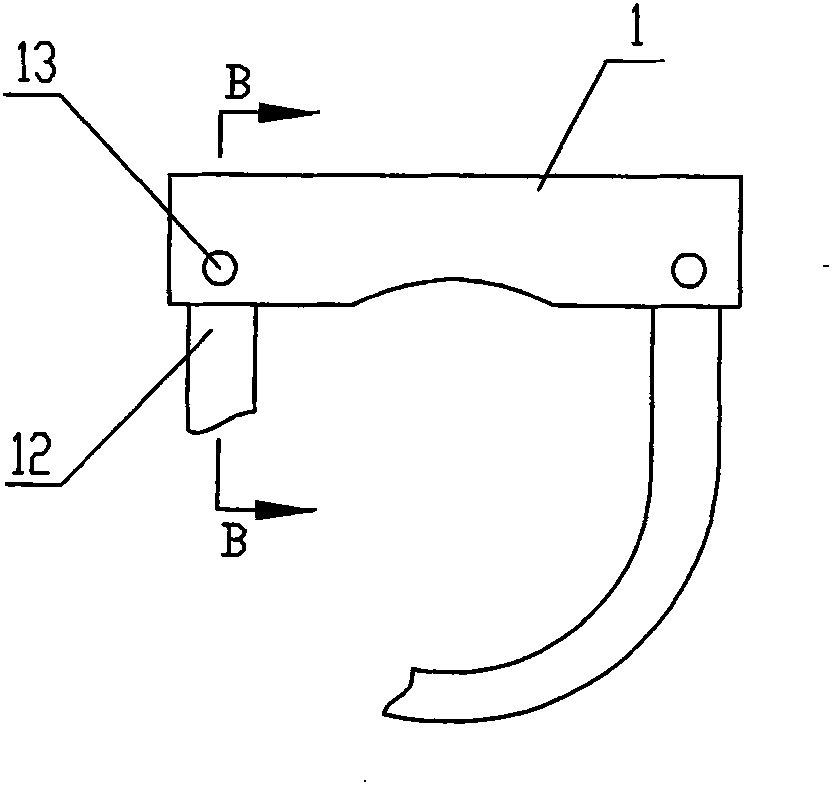

[0027] The polyethylene pipe outer crimping automatic cutting machine in this embodiment has a base 1 on which a housing 2 is mounted, and the base 1 and the housing 2 are connected by bolts to realize the compatibility and versatility of the main structure of the present invention in the application of different series of pipes . Two U-shaped fixing frames 12 are arranged below the base 1, which are movably connected by pins 13, so as to facilitate the fixing of the body on the pipe during operation.

[0028] The opening at the front end of the base 1 is provided with a cutter 3, which is a multi-tooth saw blade, connected to the transmission shaft of the first motor 5 through a connecting rod slider transmission device 4 arranged in the housing 2, and the connecting rod slider transmission device 4 Converting the rotational motion of the first motor 5 into the reciproca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com