A method for manufacturing powder tank

A powder tank and powder material technology, applied in the field of equipment manufacturing, can solve the problems of prolonging the delivery period of the powder tank, high labor intensity, and deterioration of the working environment of welding personnel, etc., to shorten the delivery period, avoid safety accidents, The effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

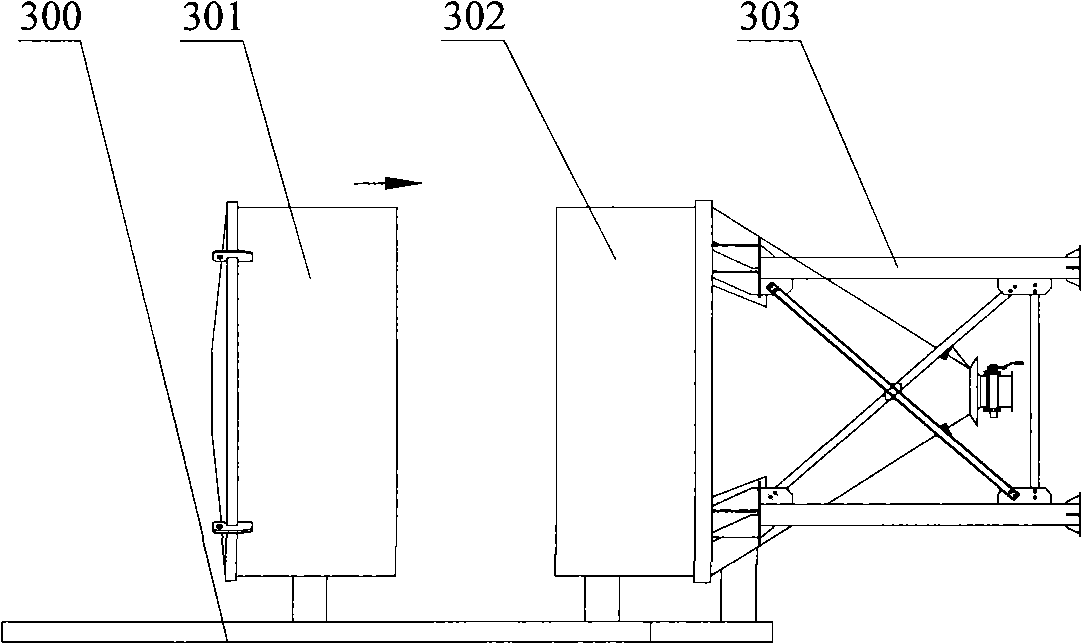

[0054] Embodiment 1 provides a kind of method of making powder tank, refer to image 3 and Figure 4 , image 3 In the method for making the powder tank provided in Example 1, the schematic diagram of the position before the top section silo and the cone section silo are docked, Figure 4 It is a schematic diagram of the position of the top section silo and the cone section silo in the first embodiment.

[0055] In the first embodiment, the manufactured powder tank includes a top section silo 301 and a cone section silo 302, the top section silo 301 and the cone section silo 302 are both circular in cross section, and the cone section silo 302 is fixed to the bracket 303 . Such as image 3 As shown, before welding the top section silo 301 and the cone section silo 302, the cone section silo 302 and the bracket 304 are fixed together on the platform 300, and the cone section silo 302 is placed horizontally so that its center line is in line with the horizontal plane Parall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com