Technological method of ladle slag thermal processing

A process method and ladle technology are applied in the field of ladle slag thermal treatment, which can solve the problems of poor slag thermal conductivity, large pollution and easy explosion, and achieve the effect of environmental protection treatment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

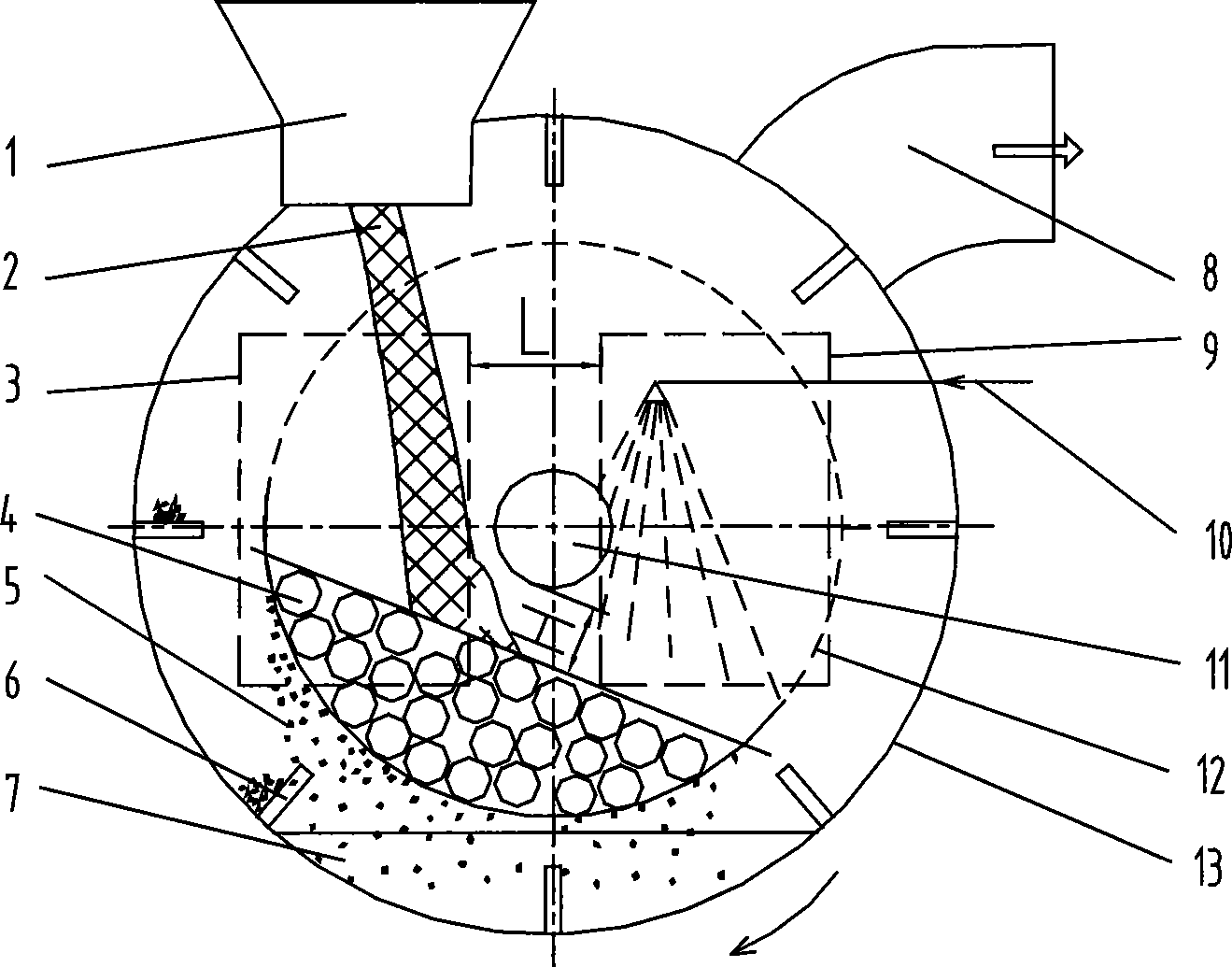

[0022] see figure 1 , a process device for thermal treatment of ladle slag, consisting of inner and outer cylinders 12, 13, the outer cylinder 13 is a closed container, the inner cylinder 12 is a squirrel cage-shaped cylinder composed of grate bars, and the inner cylinder 12 is filled with A certain number of steel balls 4.

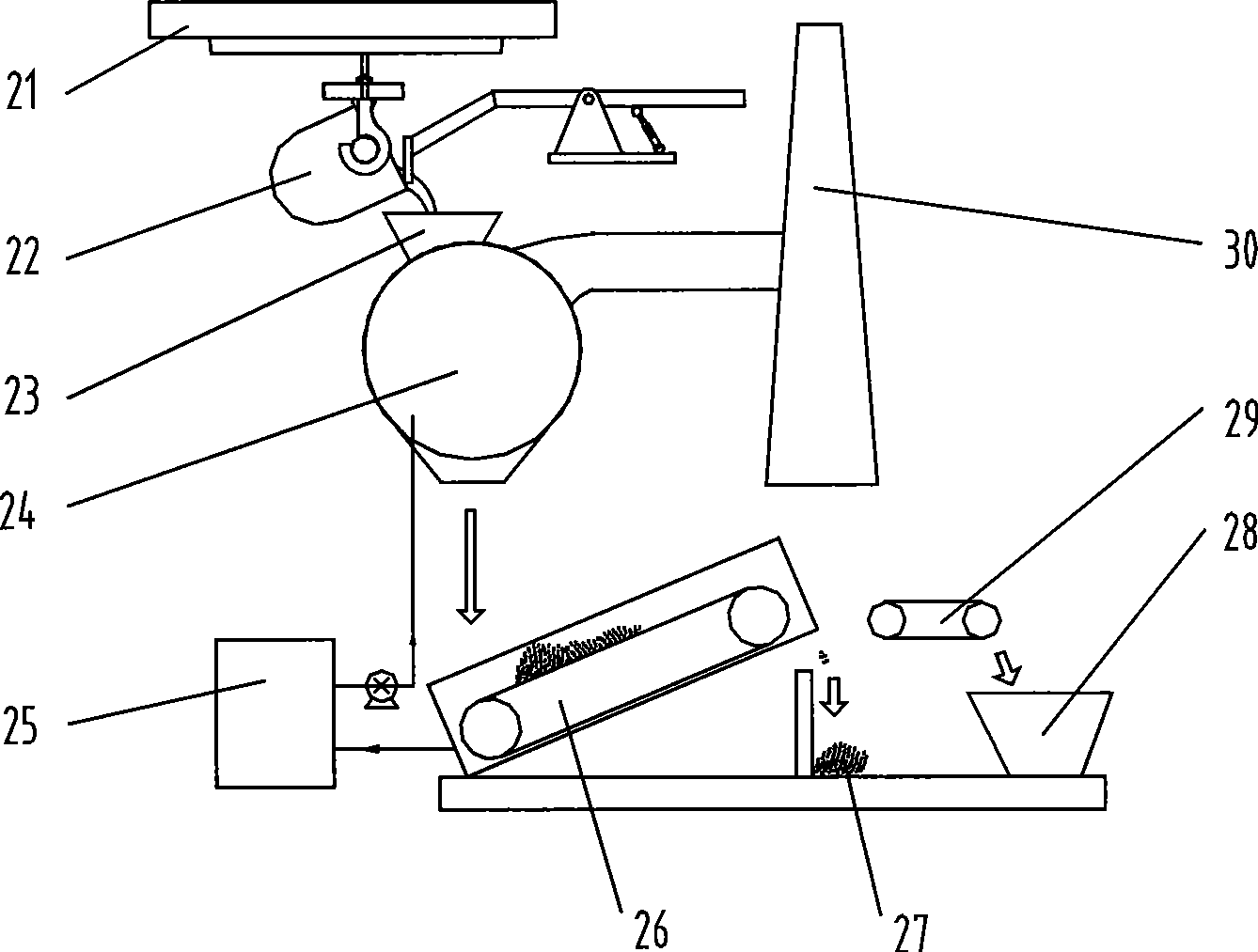

[0023] A technical method for thermal treatment of ladle slag is that ladle slag 2 enters the drum slag area 3 from the feed hopper 1, and the slag area 3 is built with steel balls 4. With the rotation of the drum 12, the molten slag 2 is covered by steel balls. After the ball 4 is cooled, the molten steel and slag are plasticized and solidified by the steel ball 4, and then brought into the spray cooling zone 9 with the rolling of the steel ball 4 to be quenched and solidified by water, and then passed through the grid t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com