Liquid crystal panel

A liquid crystal panel and glass plate technology, applied in nonlinear optics, instruments, optics, etc., can solve the problem of low yield rate of laser cutting process, achieve the effect of balancing internal stress and avoiding deflection cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

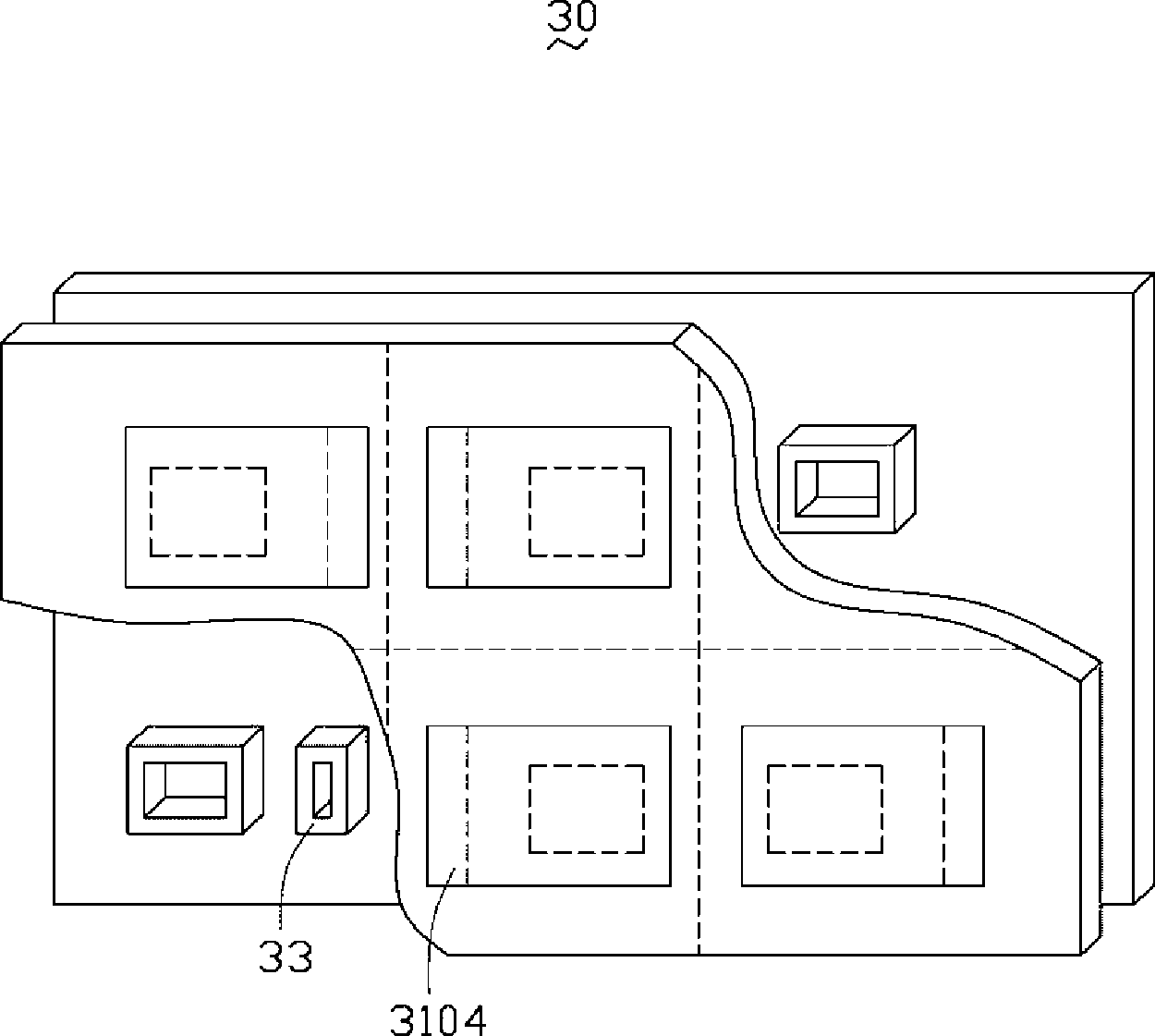

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings.

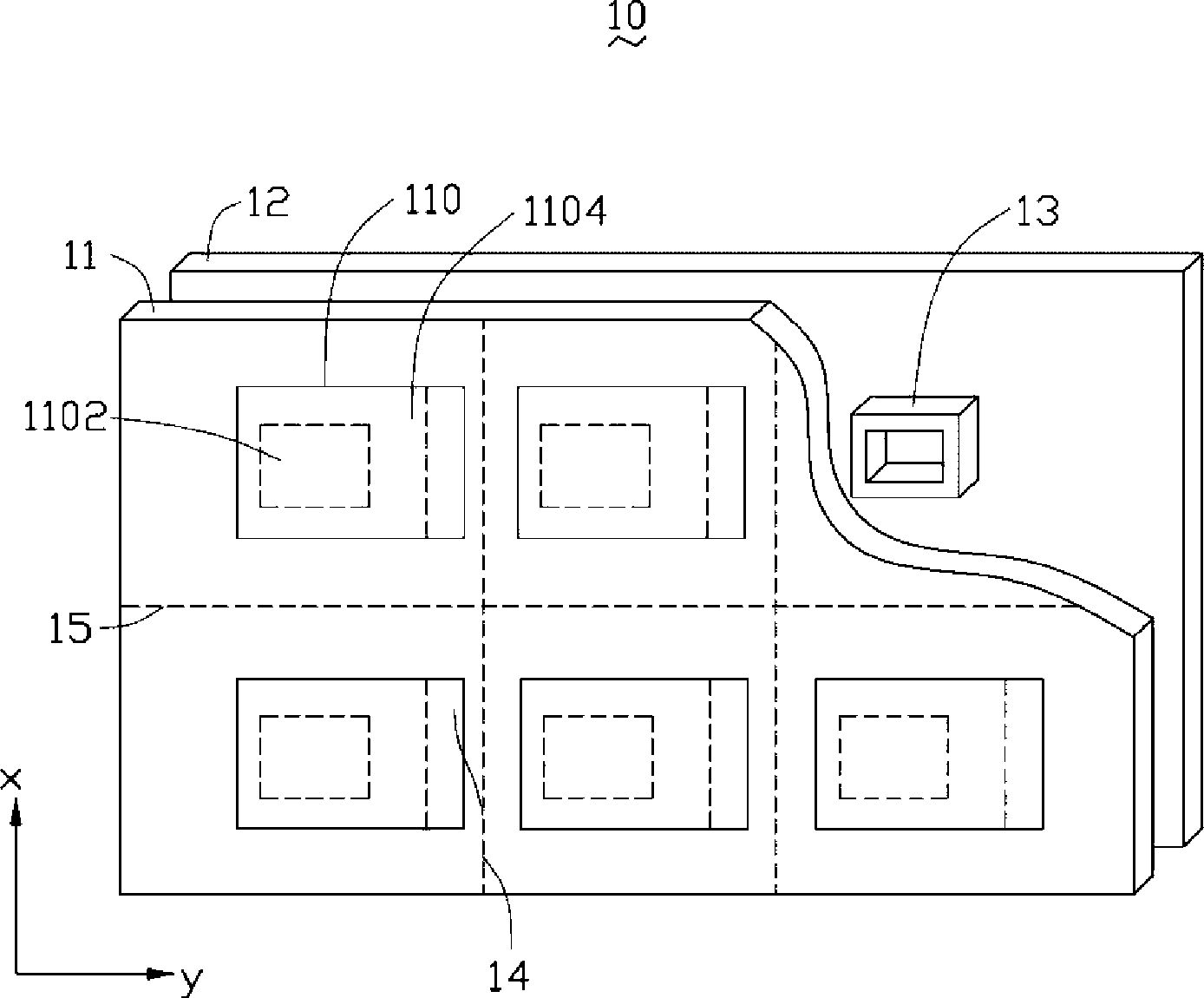

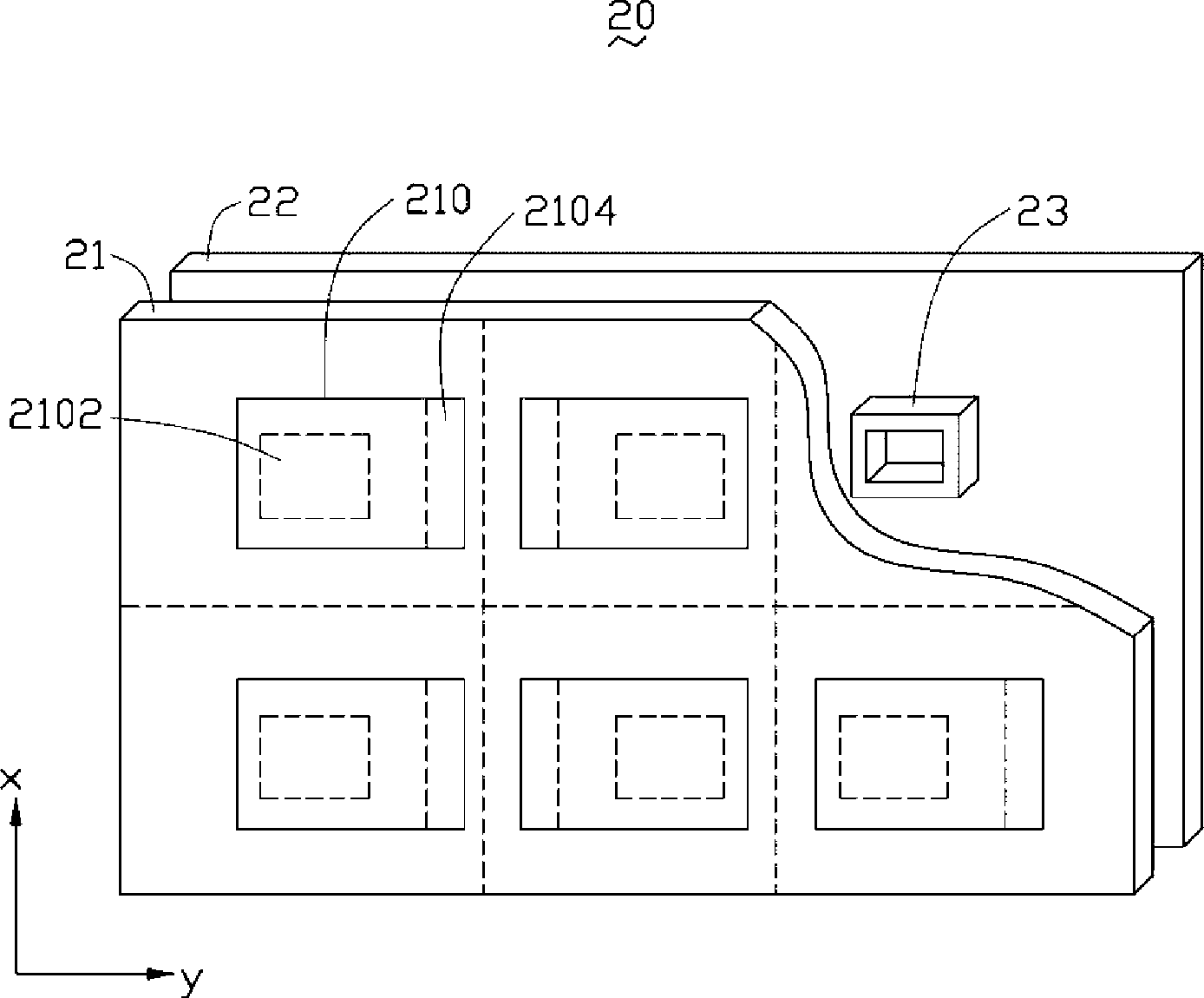

[0014] See figure 2 The liquid crystal panel 20 suitable for high-yield laser cutting provided by the first embodiment of the present invention includes a thin film transistor glass plate 21 , a color filter glass plate 22 and a first sealant 23 . The color filter glass plate 22 is located on one side of the TFT glass plate 21 . The first sealant 23 is located between the TFT glass plate 21 and the color filter glass plate 22 .

[0015] The thin film transistor glass plate 21 includes a plurality of thin film transistor units 210 arranged in an array along the x-axis direction and the y-axis direction. The plurality of thin film transistor units 210 are arranged at intervals, and each thin film transistor unit 210 includes a central area 2102 and a circuit area 2104 located on one side of the central area 2102 . The border of the central area 2102 is bond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com