Conducting wire frame and method for manufacturing same

A manufacturing method and a technology of a lead frame, which are applied in semiconductor/solid-state device manufacturing, semiconductor devices, semiconductor/solid-state device components, etc., can solve the problem of inability to control the thickness ratio at will, the degree of thickness control at will, and the time-consuming manufacturing process. Problems such as labor consumption, to achieve the effect of simplifying production costs and procedures, simplifying complexity, and increasing production speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

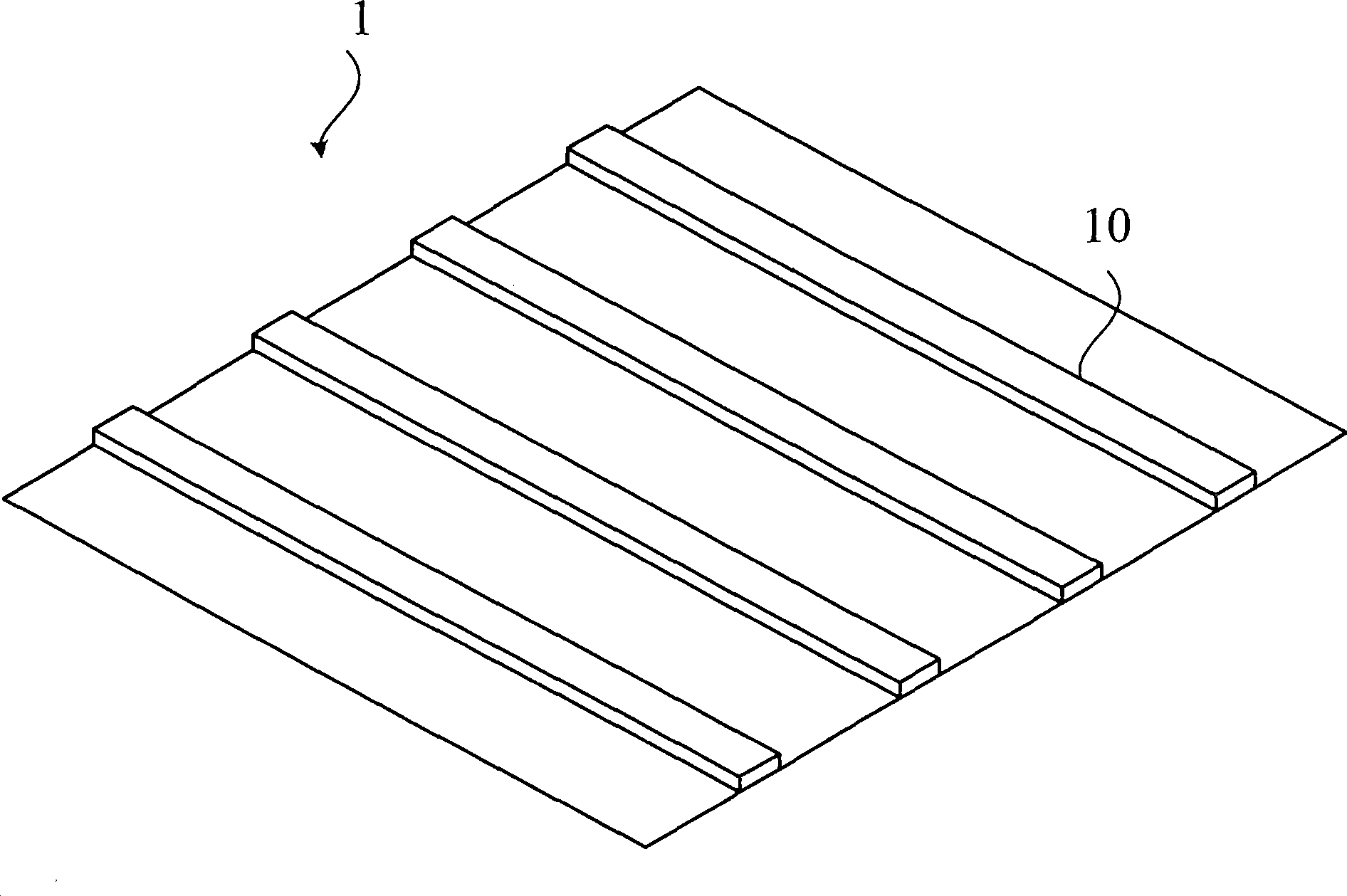

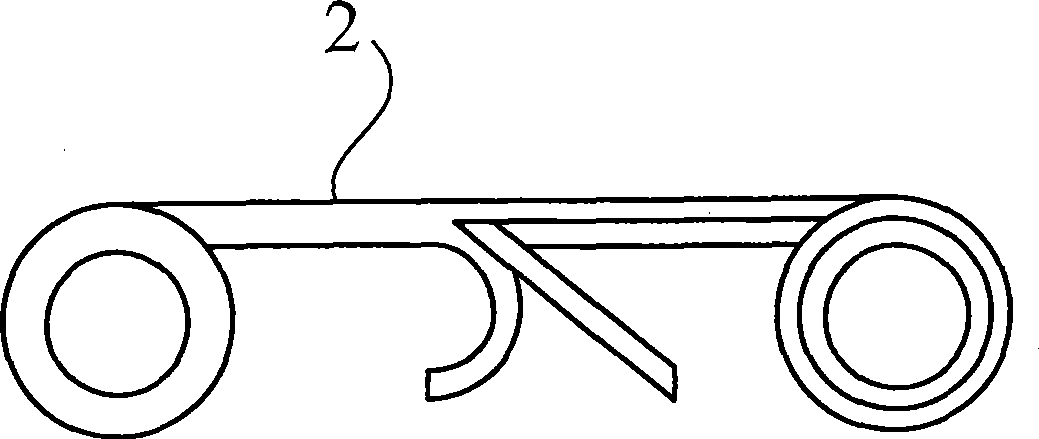

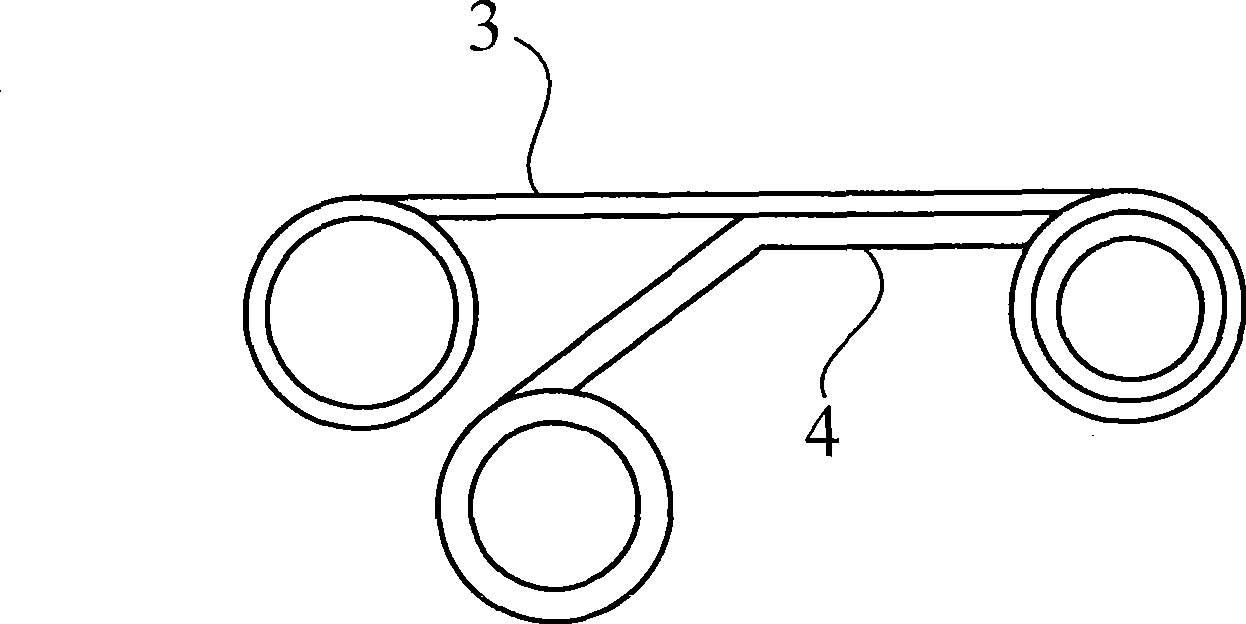

[0024] The present invention utilizes punching method to thin the strip, and then performs punching method to cut out the required components of the lead frame. In this way, the original material strips with uniform thickness can be punched out in a single production process and the thick and thin material strips can be punched out by punching equipment to produce leadframes with bases and brackets with different thicknesses. The detailed lead frame manufacturing method is as follows: Figure 4 shown in the flowchart of the , and to help understand the manufacturing process, please also refer to Figure 5A to Figure 5D manufacturing schematic. Note that, Figure 5A to Figure 5D The slash area in indicates the processing area where the punch punches or punches the strip.

[0025] First, in step S10, the first stamping is carried out, such as Figure 5A As shown, two sets of corresponding through grooves 60 are punched and formed on the material strip 6 . The through groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com