Wheel loader

A technology of wheel loader and rear frame, which is applied in the direction of motor vehicle, transportation and packaging, earth mover/shovel, etc. The effect of improving driving performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

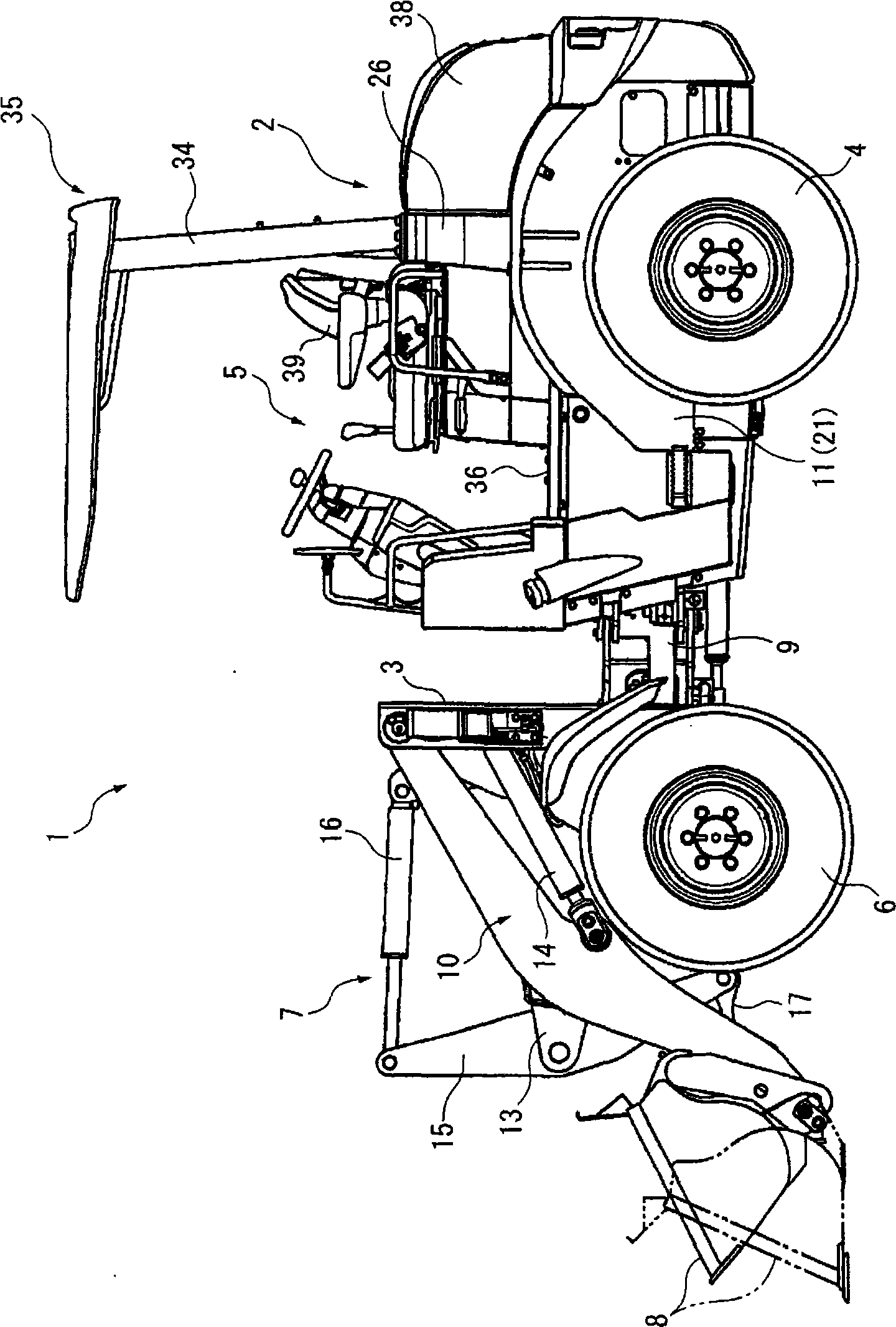

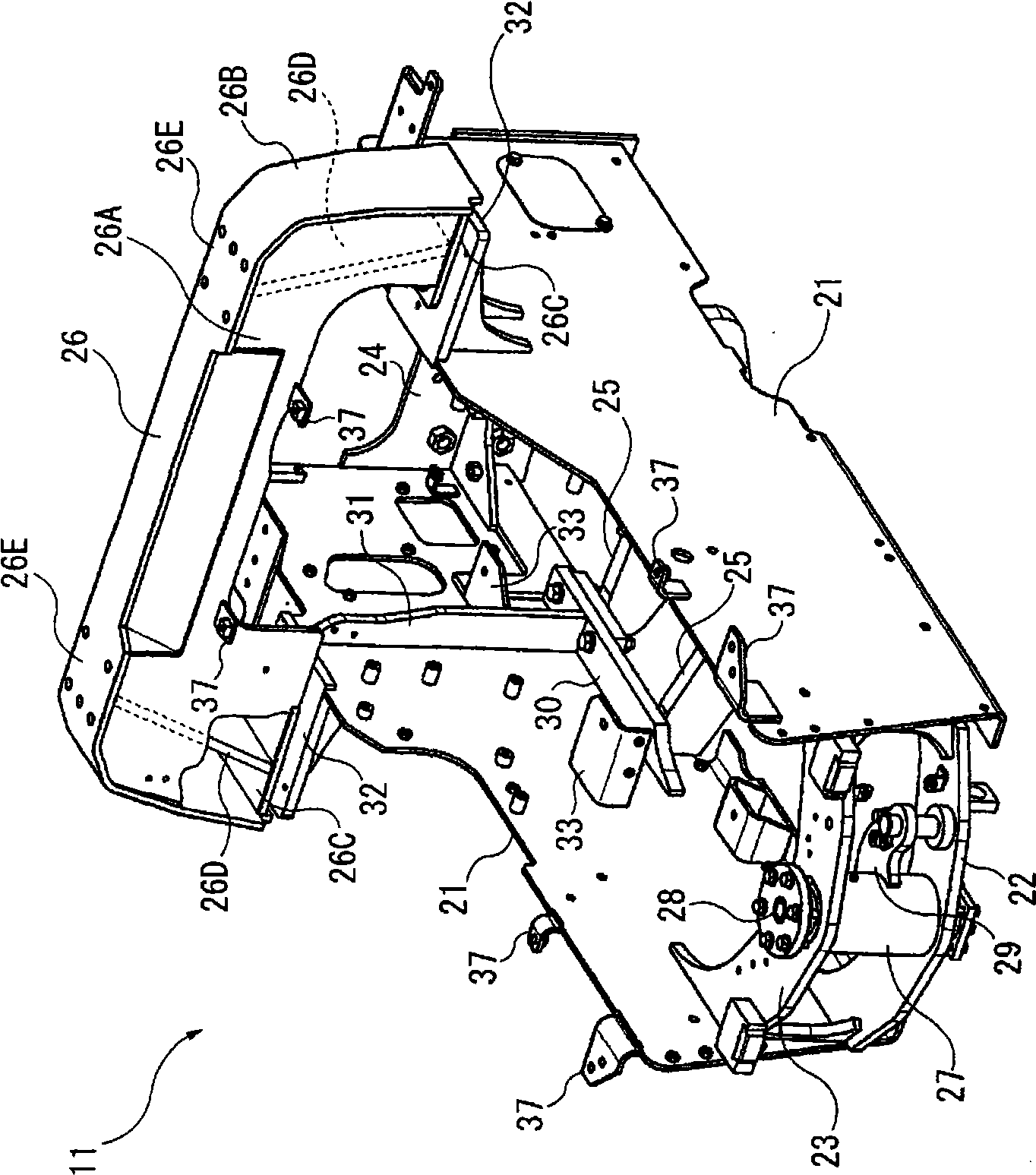

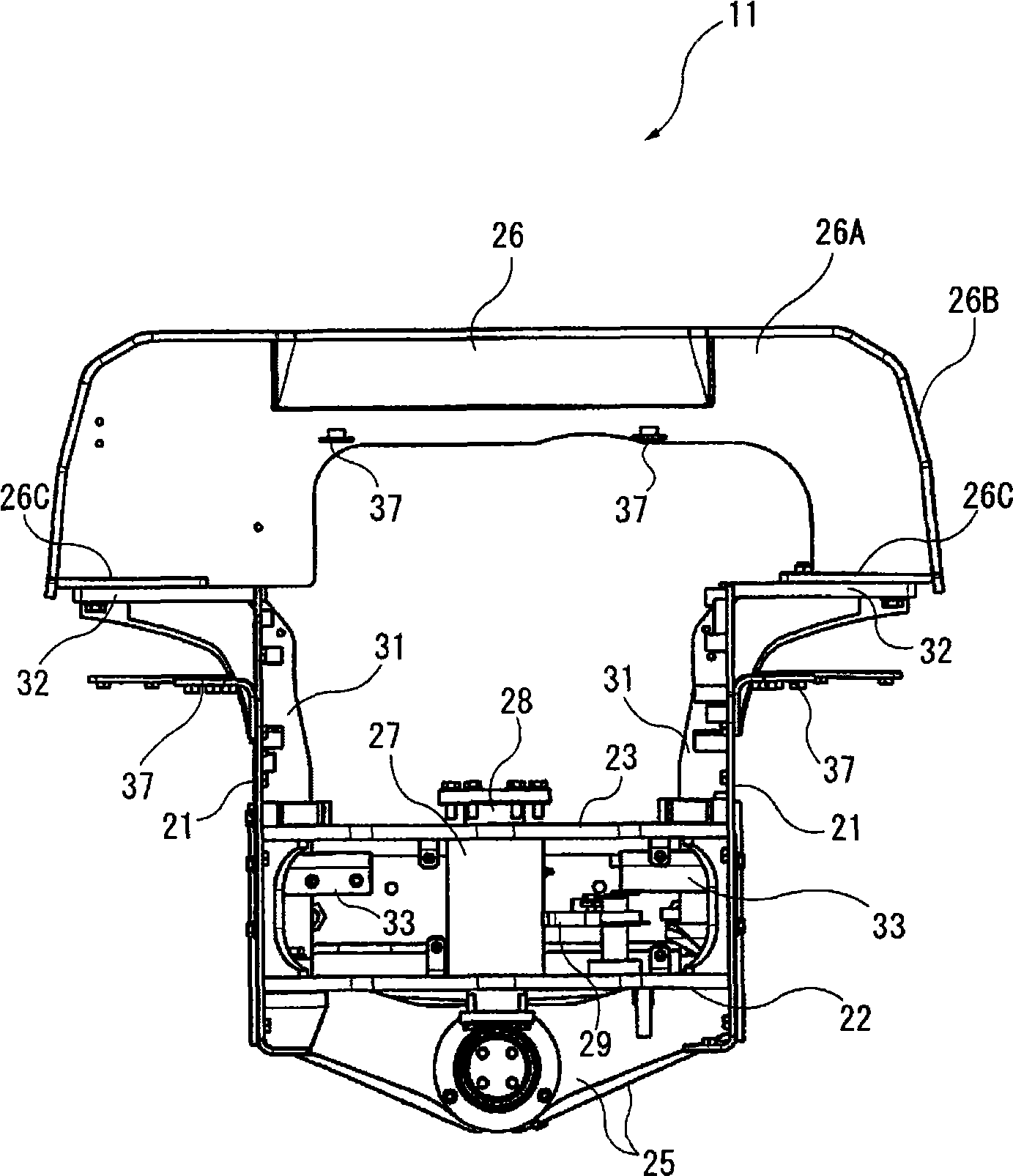

[0029] An embodiment of the present invention will be described below with reference to the drawings. figure 1 It is a side view showing the whole of the wheel loader 1 of this embodiment.

[0030] The wheel loader 1 of this embodiment has an operating weight of about 2.5 t, and is configured such that a front frame 3 is hingeably attached to the front side of a rear vehicle body 2 . The rear frame 11 of the rear vehicle body 2 is provided with rear wheels 4 and a cab 5, and accommodates an engine (not shown), a power transmission system including a hydraulic pump driven by the engine, a transmission, and the like. A seat 39 constituting the cab 5 is provided above the engine (not shown), and a roof 35 including two pillars 34 is provided behind the seat 39 . Front wheels 6 are provided on the front frame 3 , and a working device 7 is provided further forward of the front frame 3 , and a bucket 8 is attached to the front end of the working device 7 .

[0031] Among them, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com