Straw chopping apparatus in combine harvester

A technology for combine harvesters and chopping devices, applied in the direction of harvesters, cutters, crop processors, etc., can solve problems such as waste of resources, environmental pollution, blade position changes, etc., to improve service life, facilitate popularization and application, and be good The effect of dynamic balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

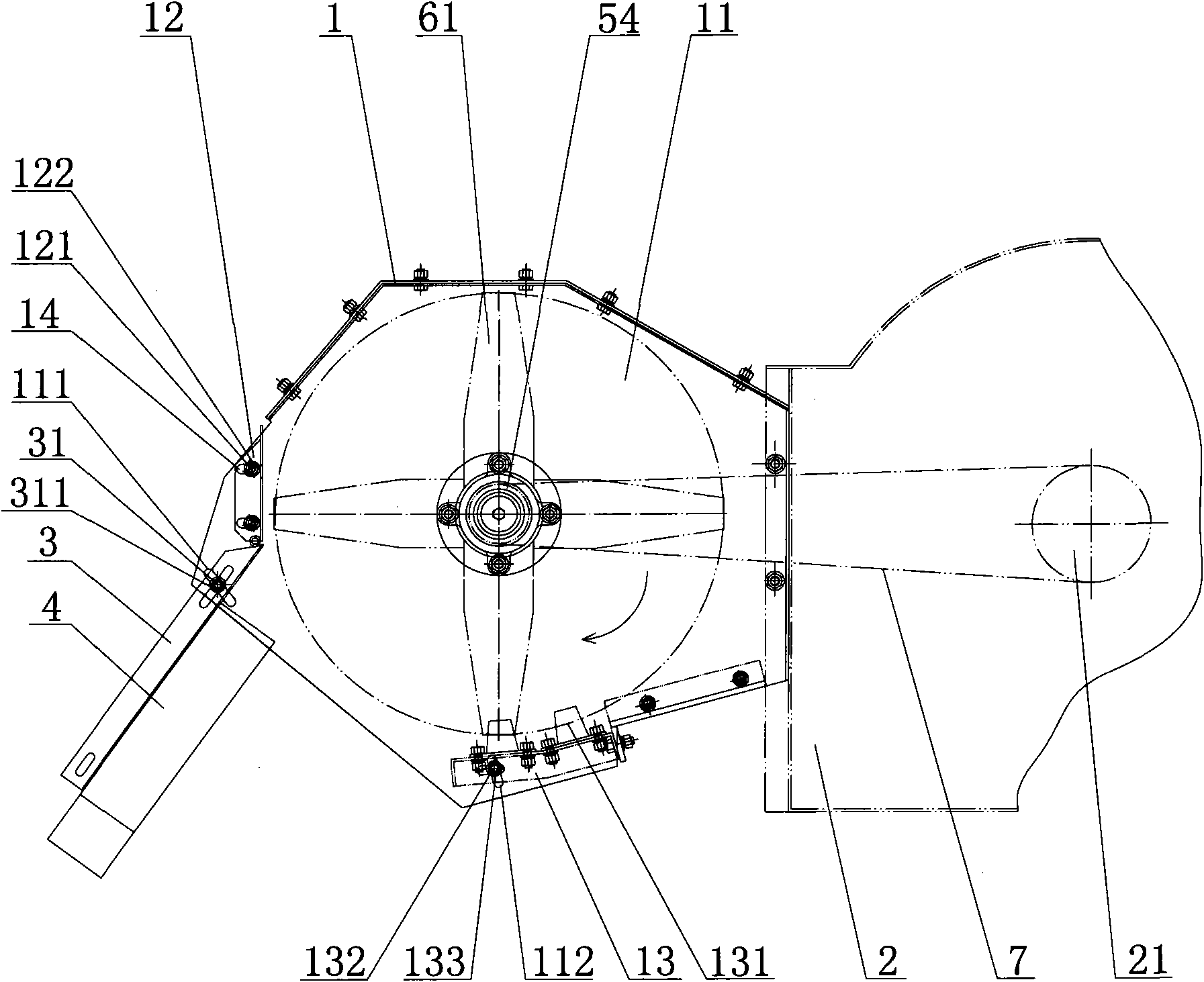

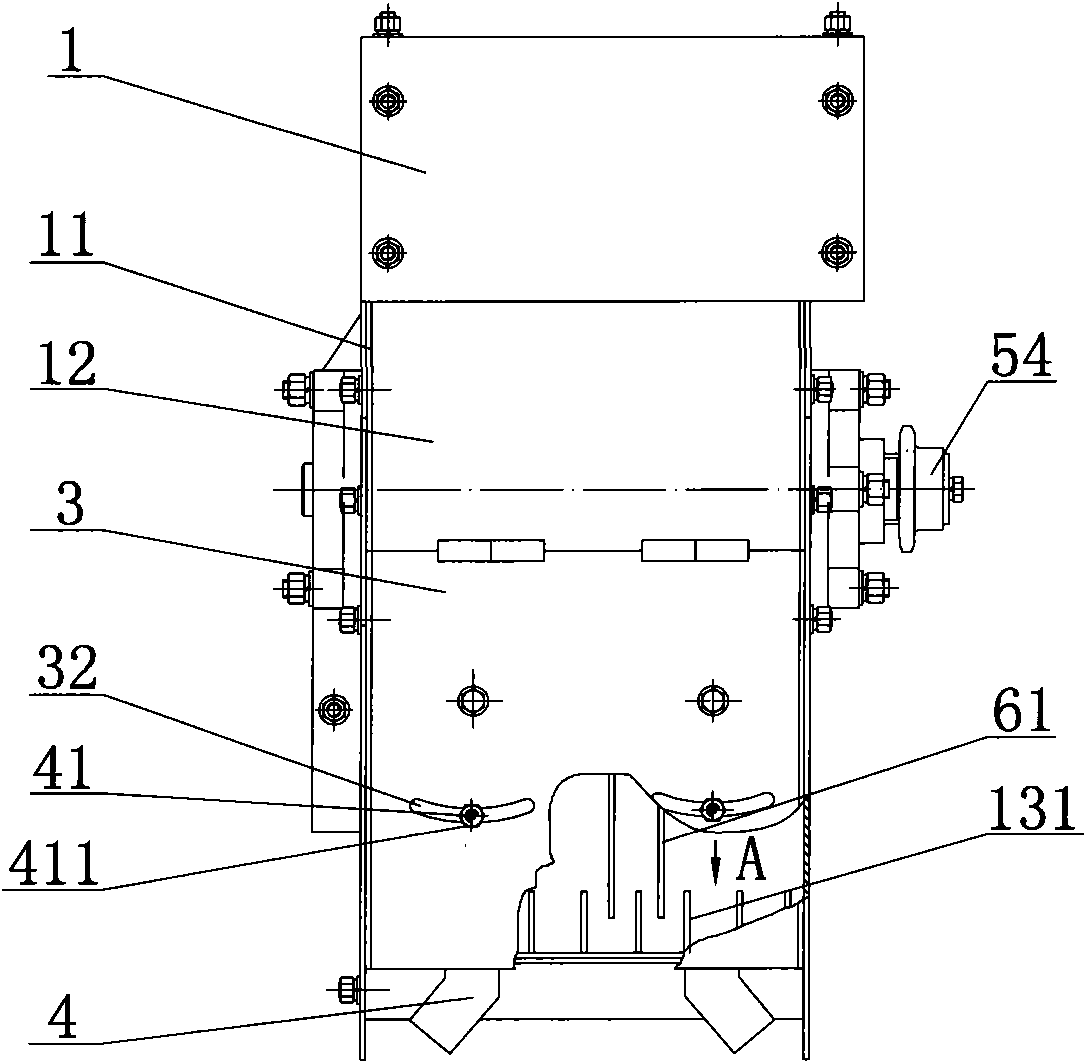

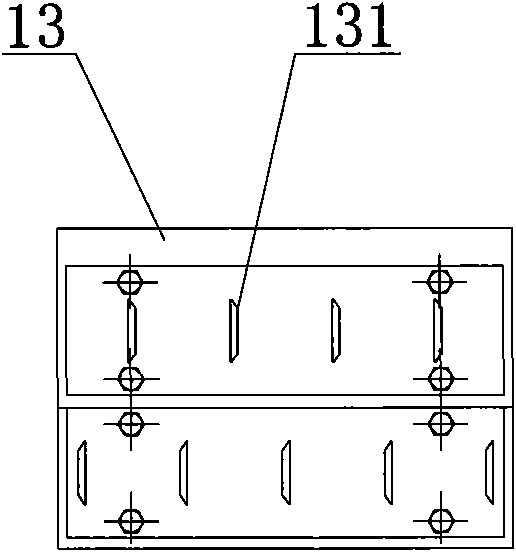

[0021] Such as figure 1 , figure 2 , image 3 As shown in the schematic diagram of the assembly structure of the present invention, a straw chopping device of a combine harvester includes a shell 1 connected to the threshing drum 2, and the left and right sides of the shell 1 are respectively provided with wall panels 11, and the shell 1 There is a rear baffle 12 at the rear end of the housing 1, and a bottom plate 13 is installed at the bottom of the housing 1. A knife-roller mechanism is installed transversely between the wallboards 11 of the housing 1, and a plurality of moving knife mechanisms are installed annularly along the axial direction of the knife-roller mechanism. The movable knife roller mechanism is provided with two movable blades 61 installed side by side, the bottom plate 13 is provided with fixed blades 131 interlaced with the positions of the movable blades 61, and the side of the wallboard 11 corresponding to the installation position of the bottom plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com