Method for solving easy fracture at tail part of minor-caliber PE double-wall bellow flare

A double-wall corrugated pipe and small-diameter technology, which is applied in the processing field of small-diameter PE double-wall corrugated pipes, can solve the problems of reduced viscosity and toughness, flaring is easy to touch the ground first, and the flaring belt is broken and damaged. Effects of ring stiffness and toughness, uniform force, and uniform wall thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

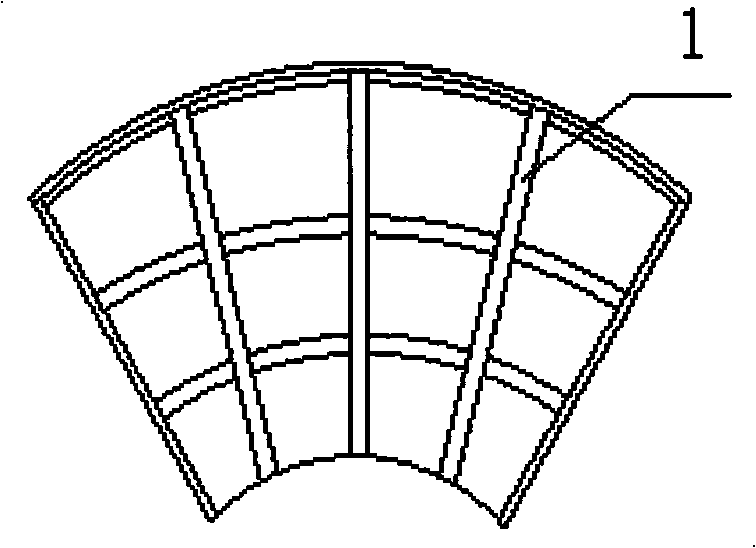

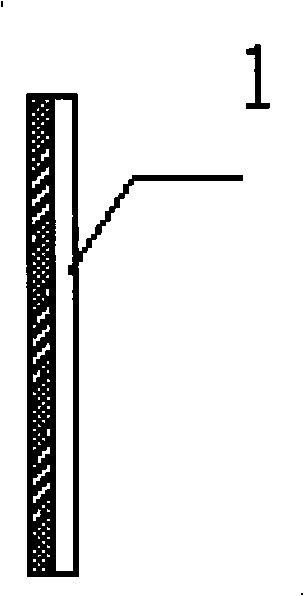

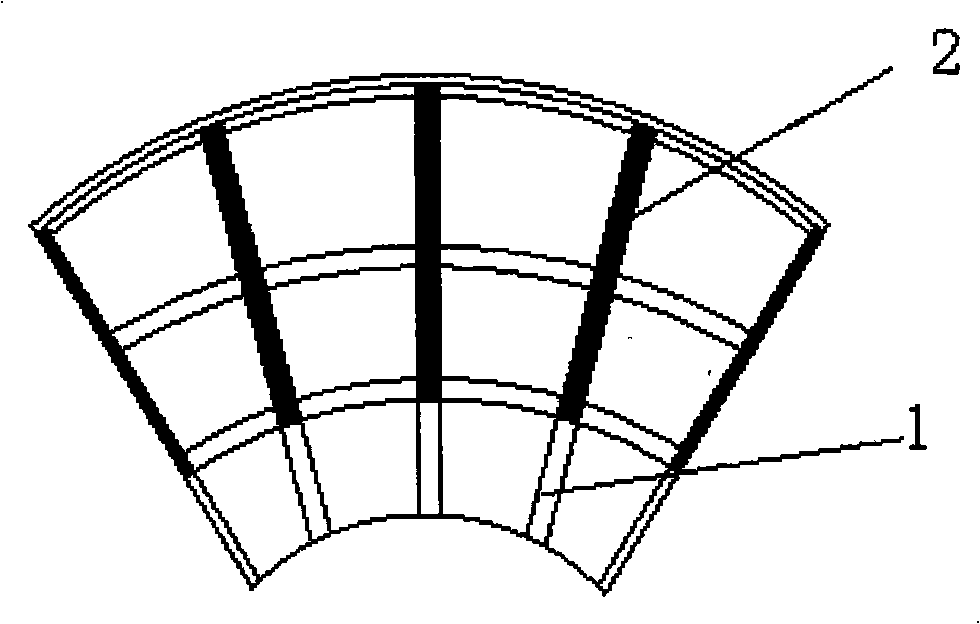

[0019] A method for solving the easy fracture of the flaring tail of a small-diameter PE double-wall corrugated pipe according to the present invention, firstly use industrial adhesives and aluminum powder to prepare a paste to obtain an adhesive material, and use this adhesive material to seal the flared mold tail part The groove is filled and glued firmly, and the unevenness is smoothed with fine sandpaper, and then the production is started to obtain PE double-wall corrugated pipe products; image 3 It is a schematic diagram of the improved part of the mold in the present invention, wherein A is the improved part. Specific steps are as follows:

[0020] 1) Adjust the aluminum powder and industrial adhesive into a paste according to a certain ratio, and use a spatula to wipe and flatten it from the groove at the tail of the flare to the top of the flare, and the bonding length will smoothly transition to the groove according to the specified value according to the diameter o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com