Shutter-style multiple row synchronous metering device

A metering device and ram technology, applied in packaging and other directions, to achieve the effects of avoiding pollution, wide measuring range, and improving material quality

Inactive Publication Date: 2010-12-01

唐山大松包装机械制造有限公司

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The multi-lane packaging machine can measure and pack multi-lane materials at the same time, which can greatly improve productivity, but how to realize multi-lane measurement and adjustment has always been a technical problem for multi-lane packaging machines

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

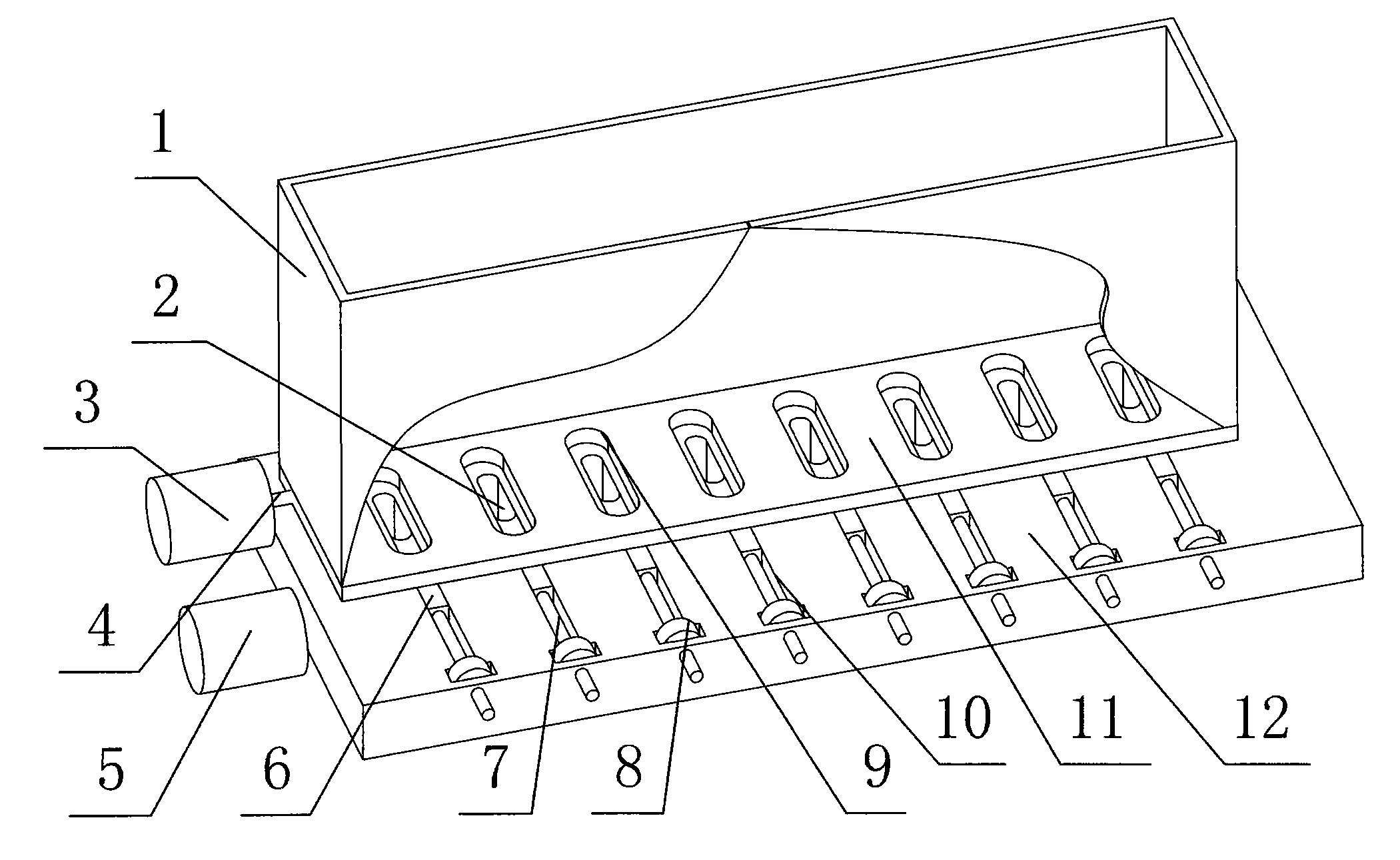

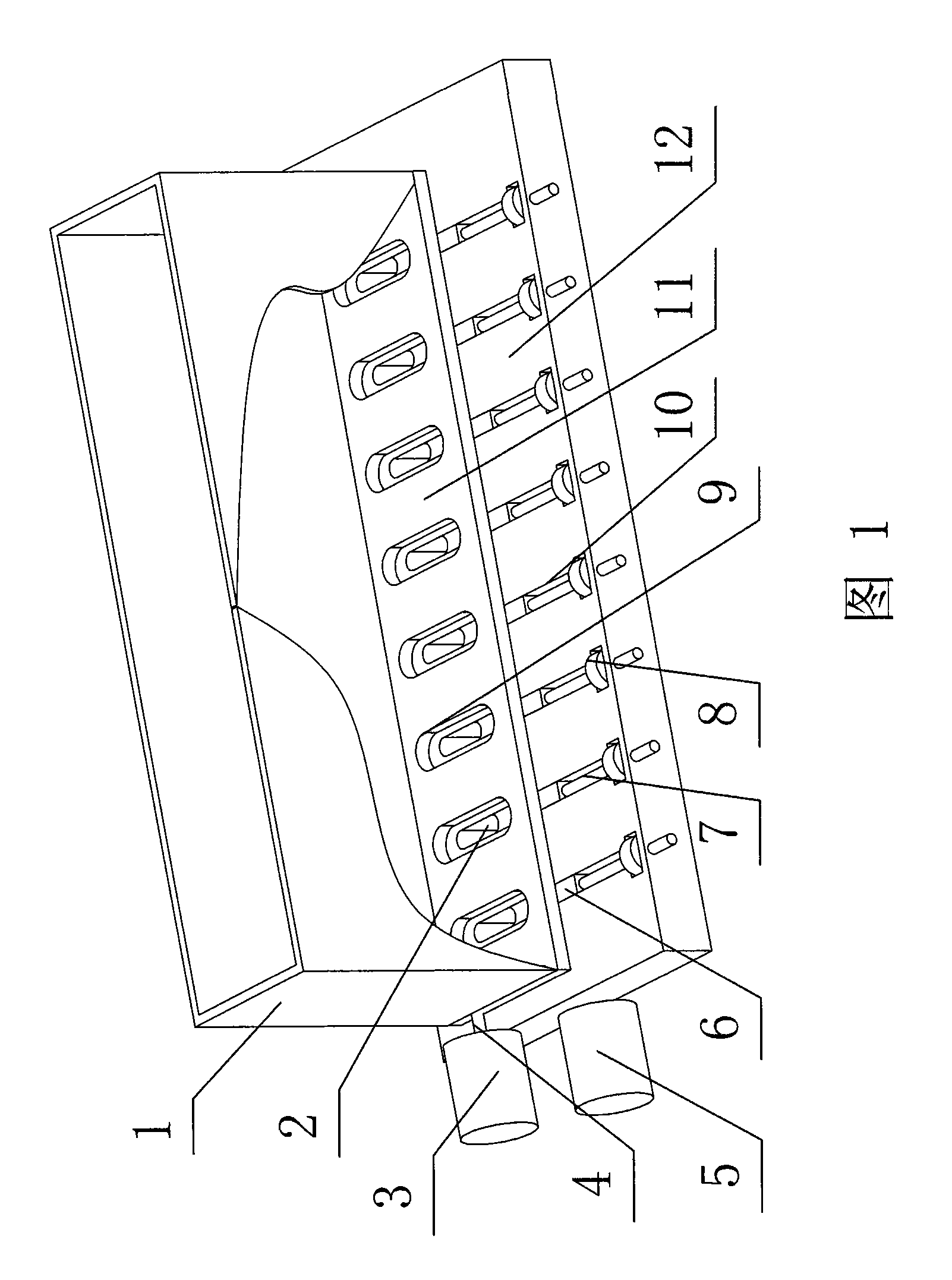

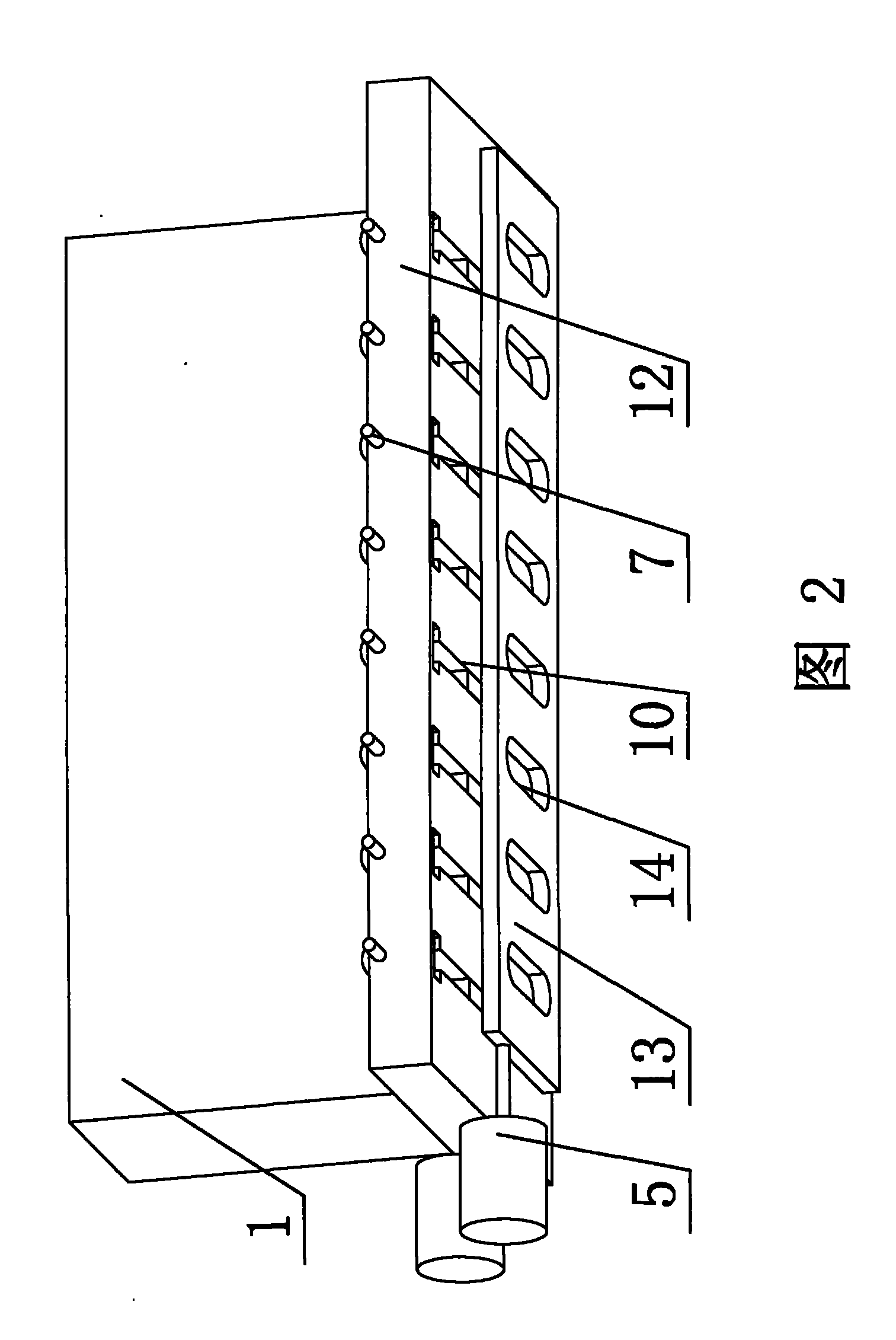

The invention relates to a metering device of packing machine, concretely a shutter-style multiple row synchronous metering device used in multiple row simultaneity metering and packing. It includes hopper with scraping flitch, metering plate and closing plate set in sequence under the hopper, the hopper and scraping flitch are jointed as one body. The aforementioned scraping flitch, metering plate and closing plate are all with elongated slot of equal-width and equal-distance, one side of the scraping flitch and closing plate is respectively connected with air cylinder, a slide mechanism is set in the elongated slot of the metering plate. Compared to the present technology, the invention has simple structure, can implement multiple row synchronous metering during the packing procedure, the metering scope is great and can fix on the amount of the materials by adjusting the slide position for the invention employs regulable link slide block structure in the metering plate, evades the extrusion and damnification from the machine itself to the materials for the integrated structure and bulk movement of the hopper and scraping flitch, diminishes the fine material content of the materials, also evades material pollution and improves quality of the materials.

Description

Gate type multi-column synchronous metering device technical field The invention relates to a metering device on a packaging machine, in particular to a gate-type multi-row synchronous metering device used for multi-row simultaneous metering and packaging. Background technique In packaging machinery, measurement is an important link in the quantitative packaging of materials. There are two measurement methods for quantitative packaging of loose materials: volumetric measurement and weighing measurement. Generally speaking, volumetric metering is simpler in structure than weighing metering, with faster metering speed and lower manufacturing cost. It is suitable for metering small doses of materials and is widely used in packaging machinery for loose granular and powder materials. In food, daily chemical, pharmaceutical and other industries, commonly used volume measurement methods include cup type, drum type, screw type, plunger type, intubation type and other forms. When s...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B37/20

Inventor 刘丰训李占贤刘坚杨玉新王洪波赵春秋邹彩侠曹钰

Owner 唐山大松包装机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com