Steam-injection boiler used for producing high-dryness superheated steam

A technology for superheated steam and steam injection boilers, applied in steam boilers, steam generation, lighting and heating equipment, etc., can solve problems such as affecting the effect of oil extraction, decreasing steam dryness, decreasing oil-steam ratio and accumulative oil production, etc. , to achieve the effect of novel structure, improved effect and reliable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

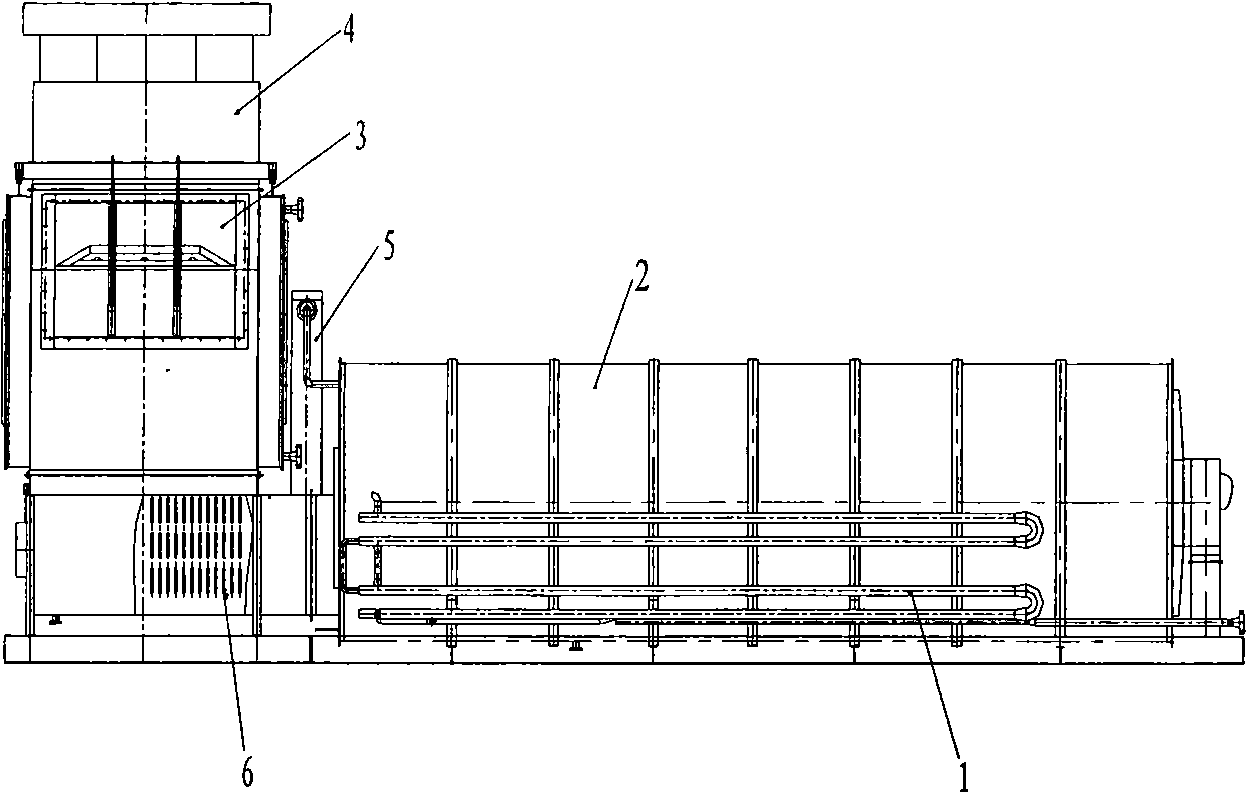

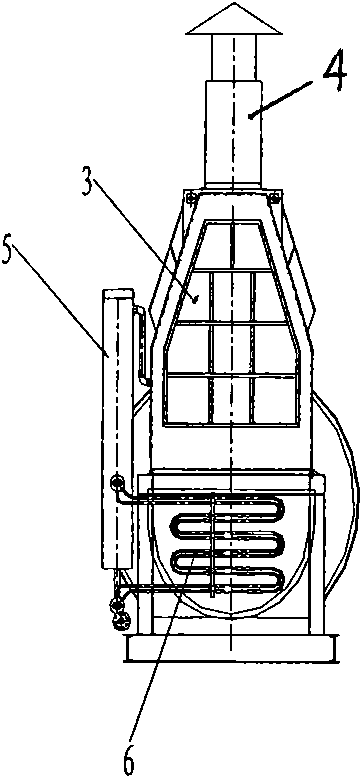

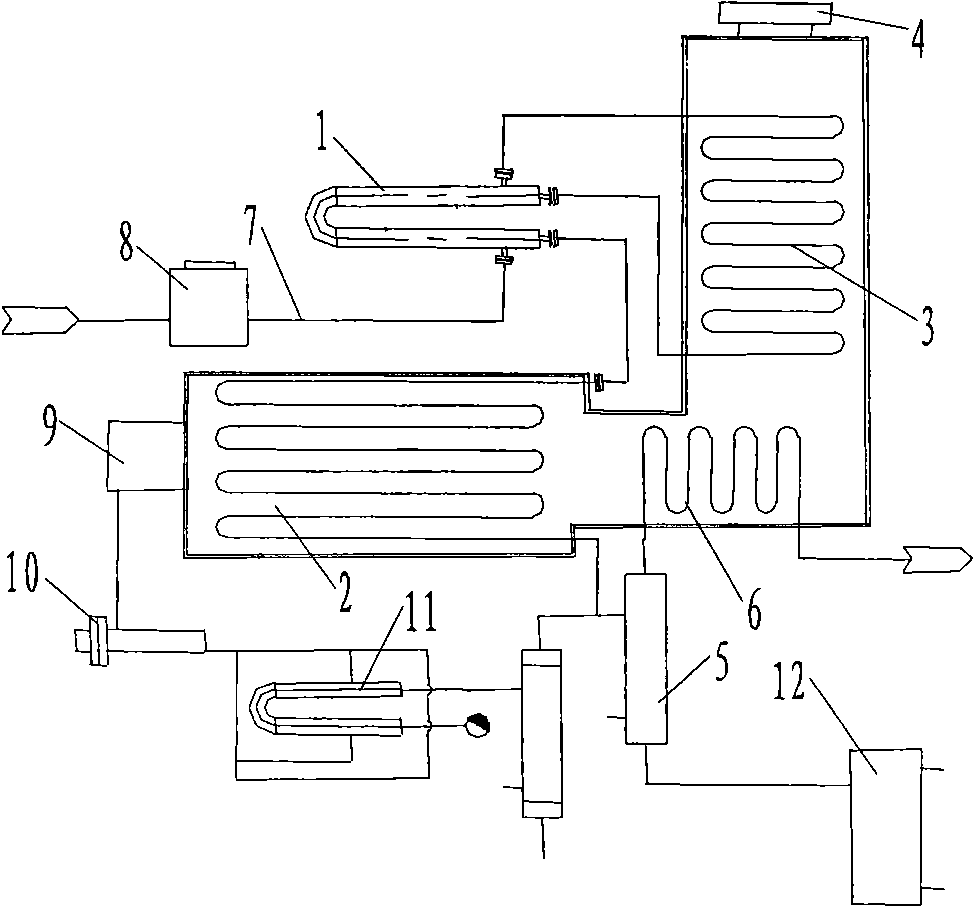

[0009] As shown in the figure, the present invention consists of a heat exchanger 1, a radiation section 2, a convection section 3, a chimney 4, a water-mounted steam-water separator 5, a superheater 6, a furnace body 7, a feed water pump 8, a burner 9, and an electric heater 10. Composed of oil heater 11 and flash tank 12. Wherein, the front and middle parts of the furnace body 7 are of horizontal structure, and the burner 9 and the radiation section 2 are respectively arranged therein, and the rear part is of a vertical structure, and the convection section 3, the chimney 4 and the superheater 6 are respectively arranged. There can be one or more external steam-water separators 5 according to the steam injection parameter requirements of the thermal recovery process. The superheater 6 is based on the different requirements of the thermal recovery process for the temperature of the superheated steam; superheaters with convective or semi-radiant screen, radiant and composite s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com