Silicon-killed steel wire material and spring

A technology of silicon-killed steel and wire rods, applied in low internal friction springs, spring/shock absorbers, mechanical equipment, etc., can solve problems such as fatigue strength, impossibility, and difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

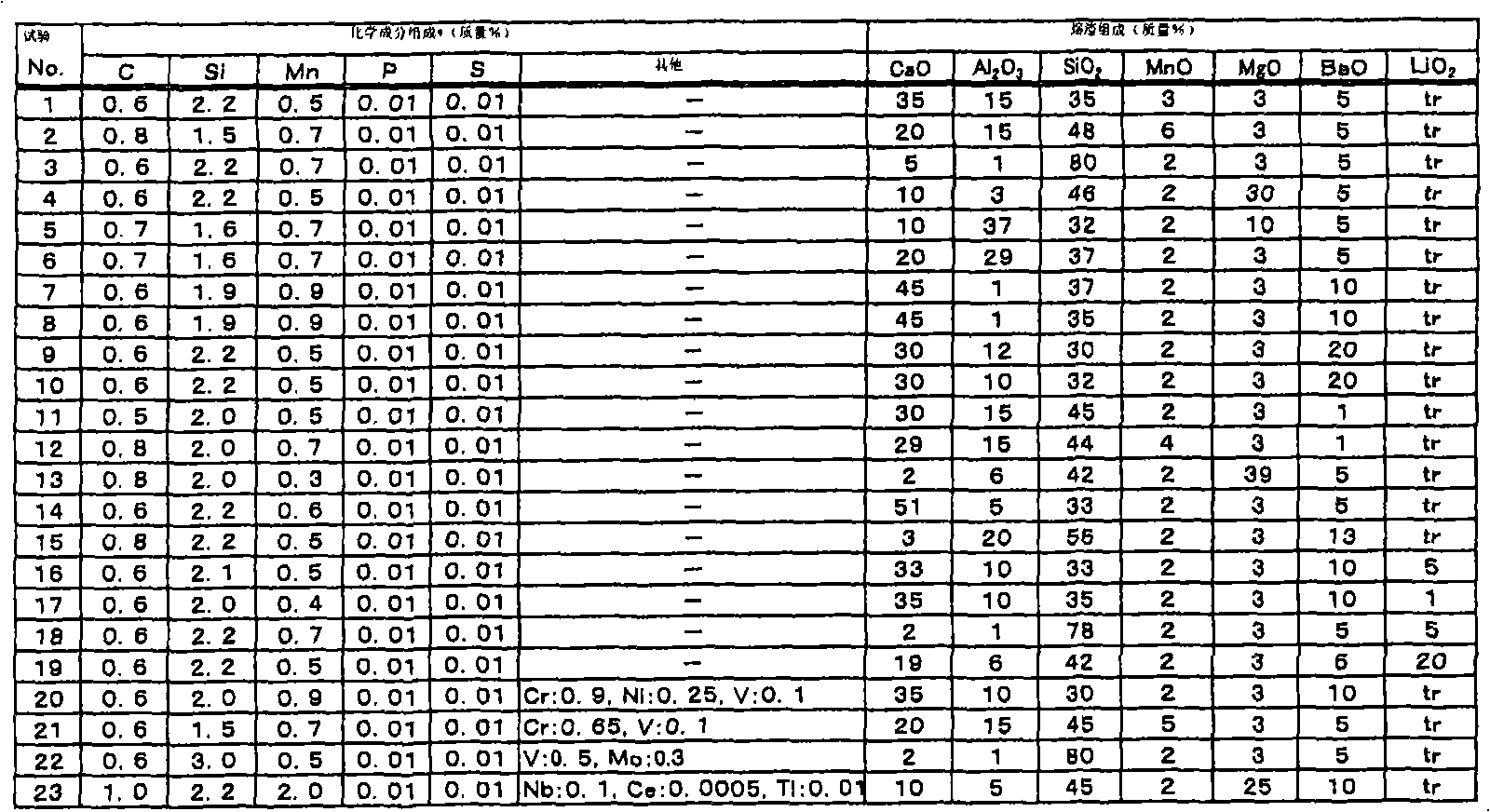

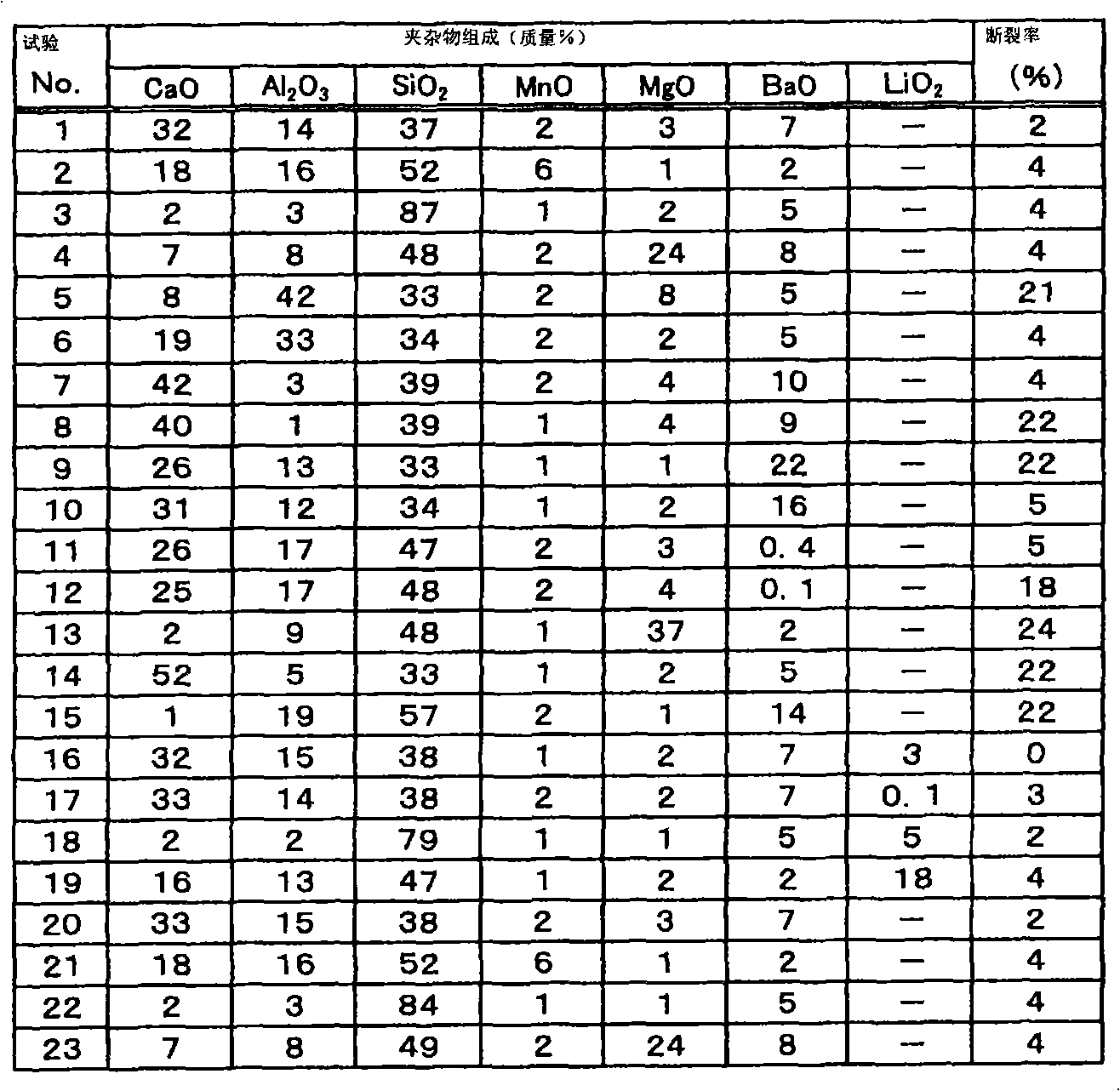

[0103] Experiments are implemented at real machine or lab level. That is to say, the actual machine taps the molten steel smelted in the converter into the ladle (the laboratory is smelting 500kg of molten steel, which simulates the molten steel tapped from the converter), and adds various fluxes to adjust the composition to make it As appropriate, electrode heating and argon bubbling are performed, and molten steel treatment (slag refining) is performed. In addition, alloy elements such as Ca, Mg, Ce, Ba, Li, etc. are added during the molten steel treatment as needed. Next, the molten steel is cast into a steel ingot (casting is carried out in a mold capable of obtaining the same cooling rate as the real machine at the laboratory level). The obtained steel ingot was forged and hot-rolled to obtain a steel wire rod with a diameter of 8.0 mm.

[0104] For each obtained steel wire rod, the composition of oxide inclusions in the wire rod was measured, and an evaluation test sim...

Embodiment 2

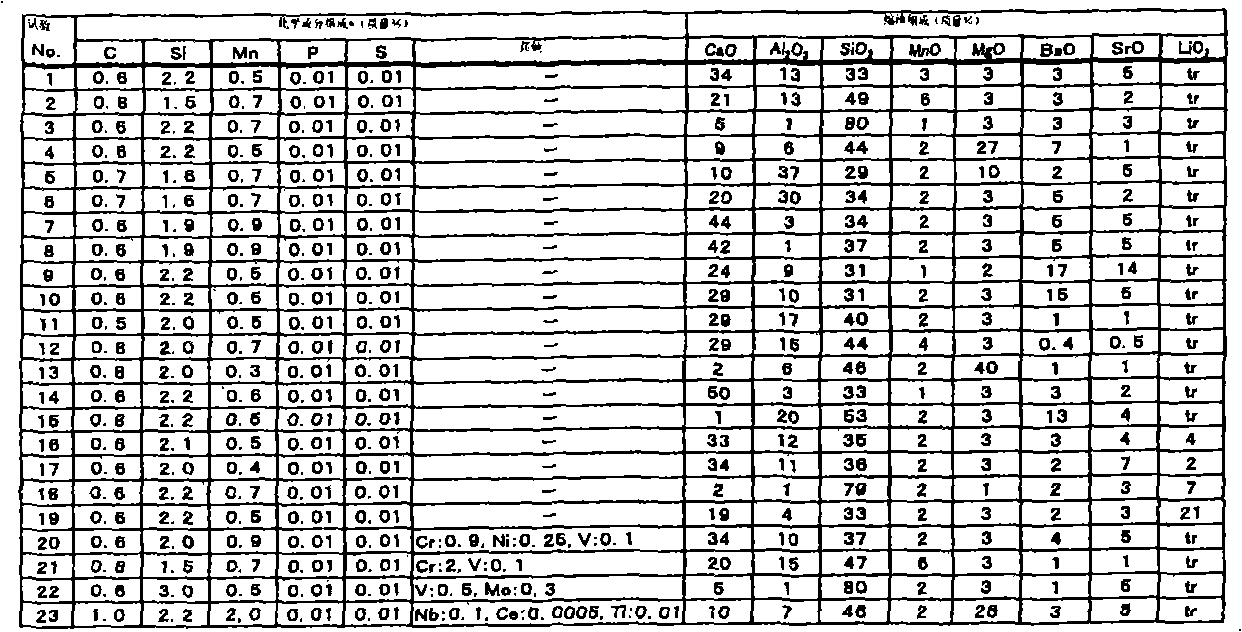

[0140] Experiments are implemented at real machine or lab level. That is to say, the actual machine taps the molten steel smelted in the converter into the ladle (the laboratory is smelting 500kg of molten steel, which simulates the molten steel tapped from the converter), and adds various fluxes to adjust the composition to make it If appropriate, implement electrode heating and argon blowing, and implement molten steel treatment (slag refining). In addition, alloy elements such as Ca, Mg, Ce, Ba, Sr, and Li are added during the molten steel treatment as needed. Next, the molten steel is cast into a steel ingot (casting is carried out in a mold capable of obtaining the same cooling rate as the real machine at the laboratory level). The obtained steel ingot was forged and hot-rolled to obtain a steel wire rod with a diameter of 8.0 mm.

[0141] For each obtained steel wire rod, the composition of oxide inclusions in the wire rod was measured, and an evaluation test simulatin...

Embodiment 3

[0177] Experiments are implemented on a real machine (or laboratory level). That is, the actual machine is to tap molten steel smelted in a converter into a ladle (the laboratory is to smelt 500kg of molten steel, which simulates the molten steel tapped from a converter), add various fluxes, implement composition adjustment, and electrode heating And argon blowing, the implementation of molten steel treatment (slag refining). In addition, after adjusting other components, Ca, Mg, Ce, Ba, Li, etc. were added to the molten steel treatment as needed, and kept for 5 minutes or more. The obtained steel ingot was forged and hot-rolled to obtain a steel wire rod having a diameter of 8.0 mm.

[0178] For each of the obtained steel wire rods, the contents of Ba and Li in the steel were measured by the following method, and an evaluation test simulating a rotational bending fatigue test of a valve spring was performed.

[0179] [Contents of Ba and Li in steel]

[0180] 1) When the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com