Combustion apparatus for a gas boiler

A combustion device, gas boiler technology, applied in the direction of gas fuel burners, burners, combustion methods, etc., can solve impossible problems and achieve the effect of increasing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] Exemplary embodiments of the present invention will be described below with reference to the accompanying drawings.

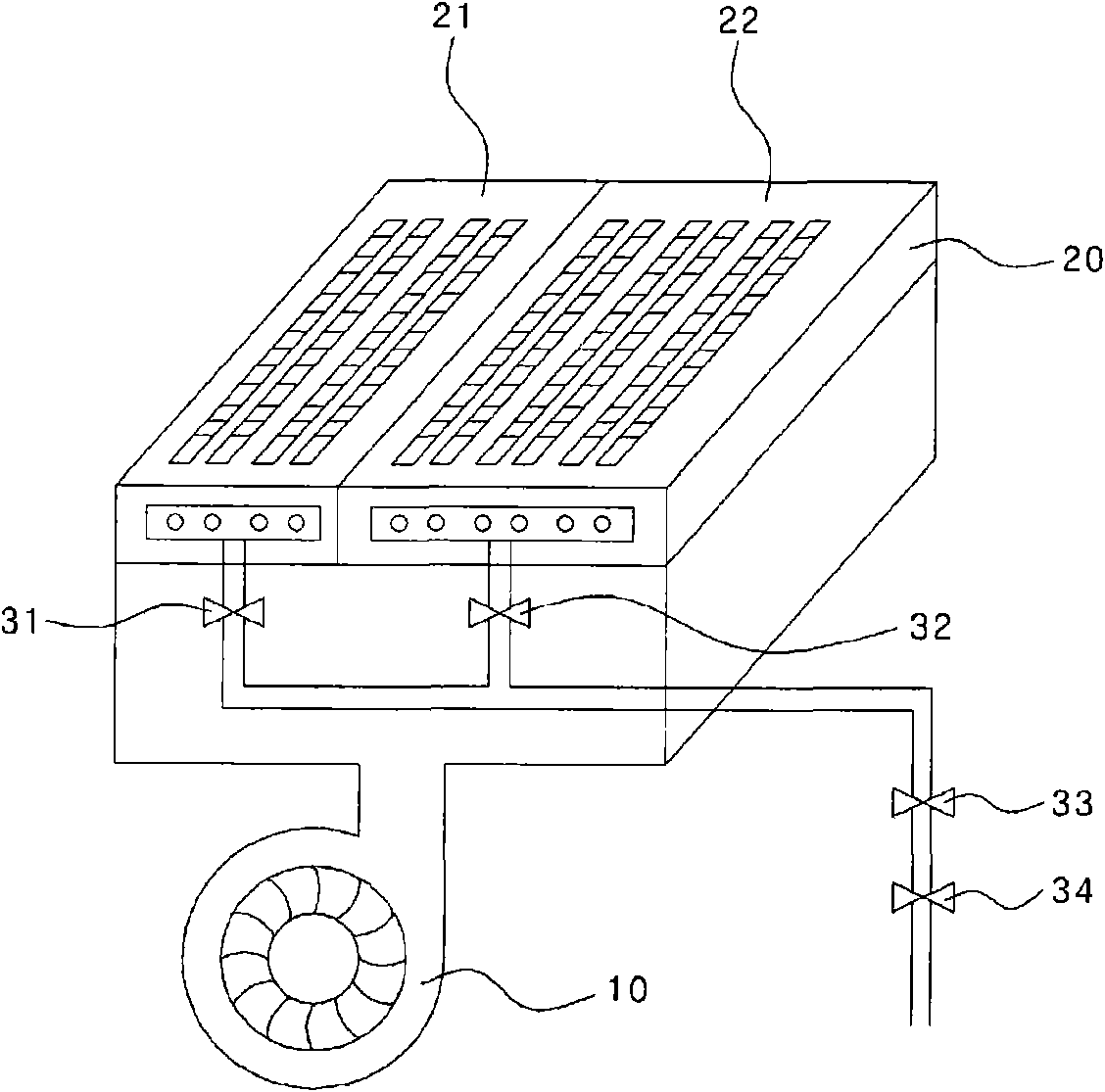

[0035] Figure 4 is a schematic diagram showing a combustion apparatus according to one embodiment of the present invention.

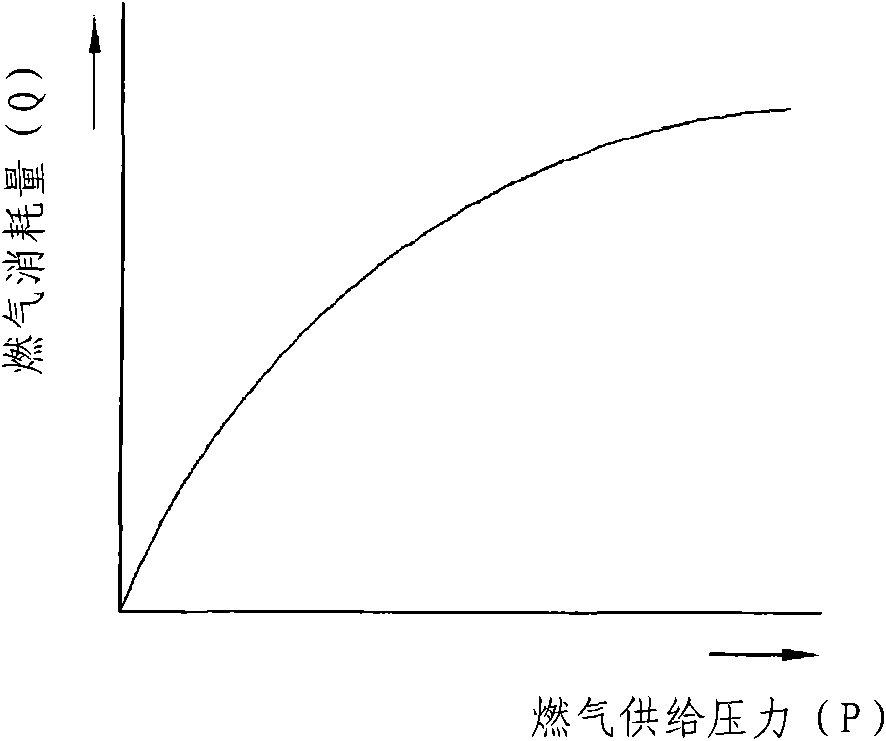

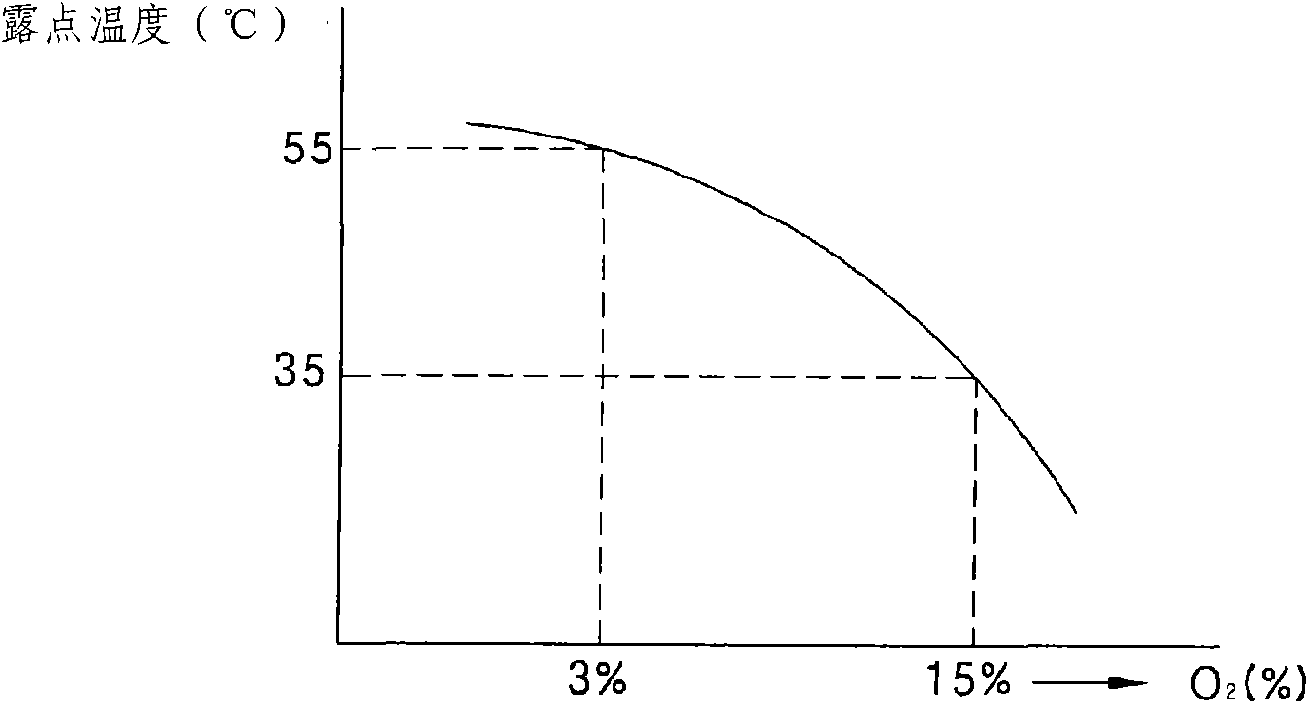

[0036] The present invention provides a structure of a combustion device capable of increasing TDR of a burner and reducing residual air in order to maintain high efficiency in a low output region. An example of the structure of the combustion device according to the present invention will combine Figure 4 to describe. The combustion apparatus includes a blower 110 for supplying air required for combustion; a proportional control valve 153 for adjusting the supply flow rate of gas; a nozzle member 140 which is connected to the proportional control valve 153 and supplies gas according to the opening and closing of auxiliary valves 151 and 152 , and includes a plurality of nozzles 141 and 142 connected in parallel to each other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com