High-efficiency filter

A high-efficiency filter and filter element technology, applied in the fields of dispersed particle filtration, chemical instruments and methods, dispersed particle separation, etc., can solve the problems of easy falling off and oxidation, shell corrosion, damage to the filter screen, etc. The effect of prolonging the service life and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

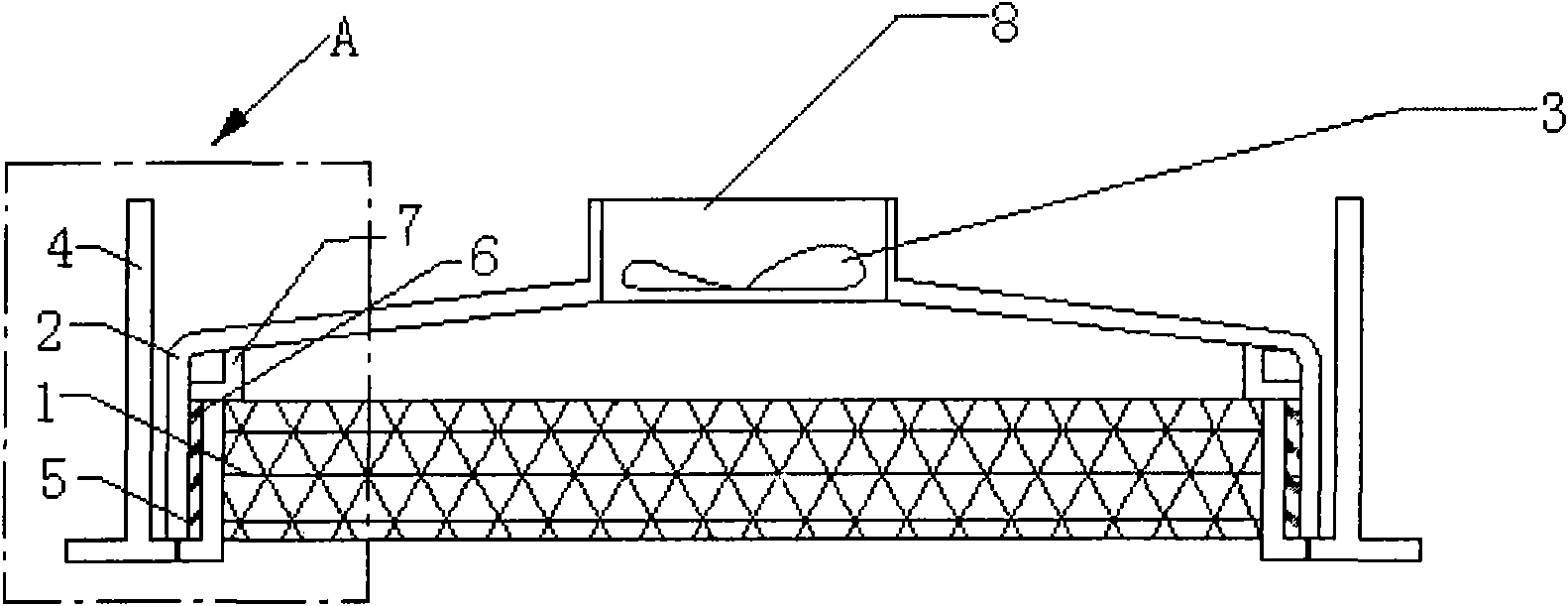

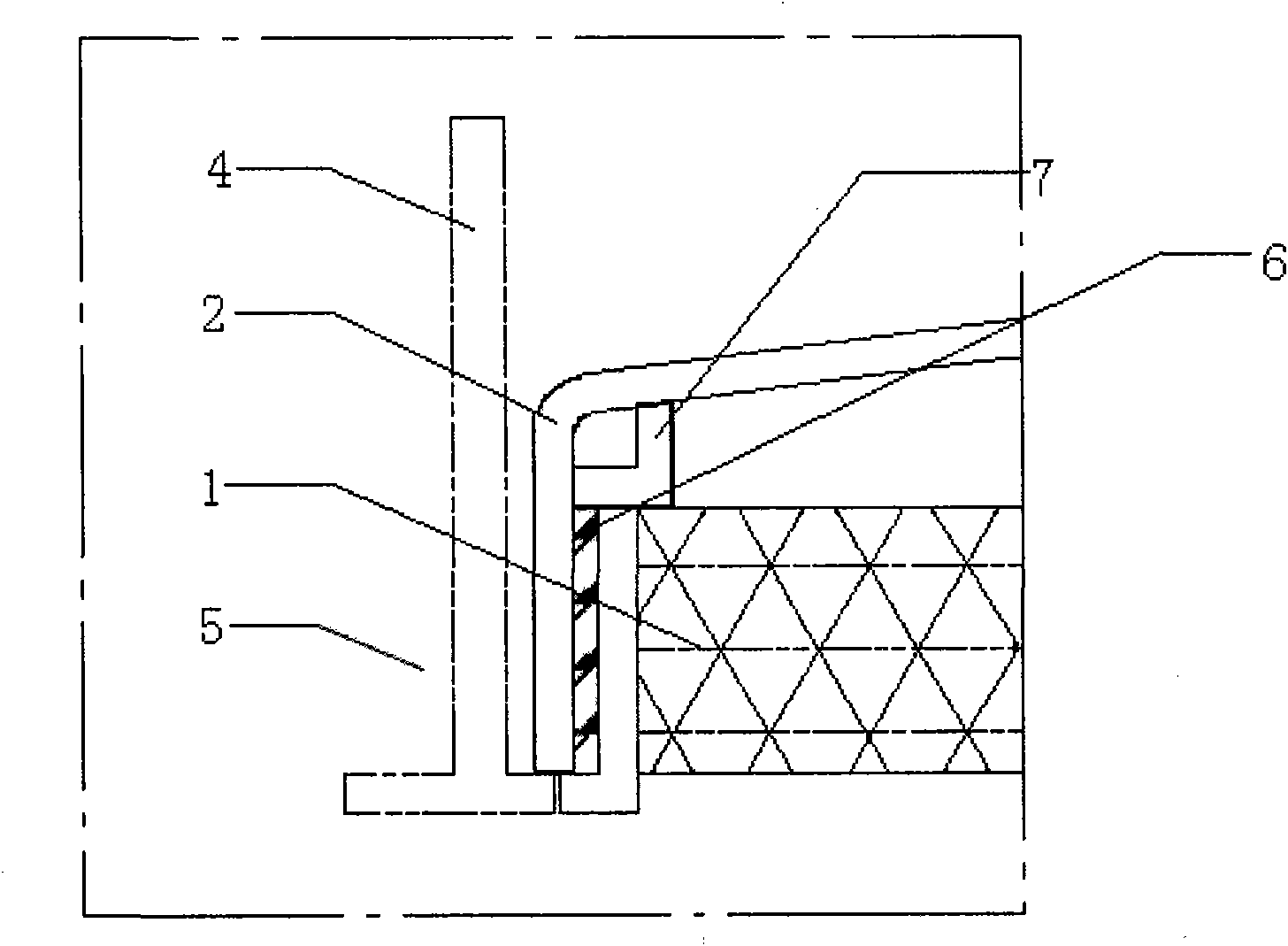

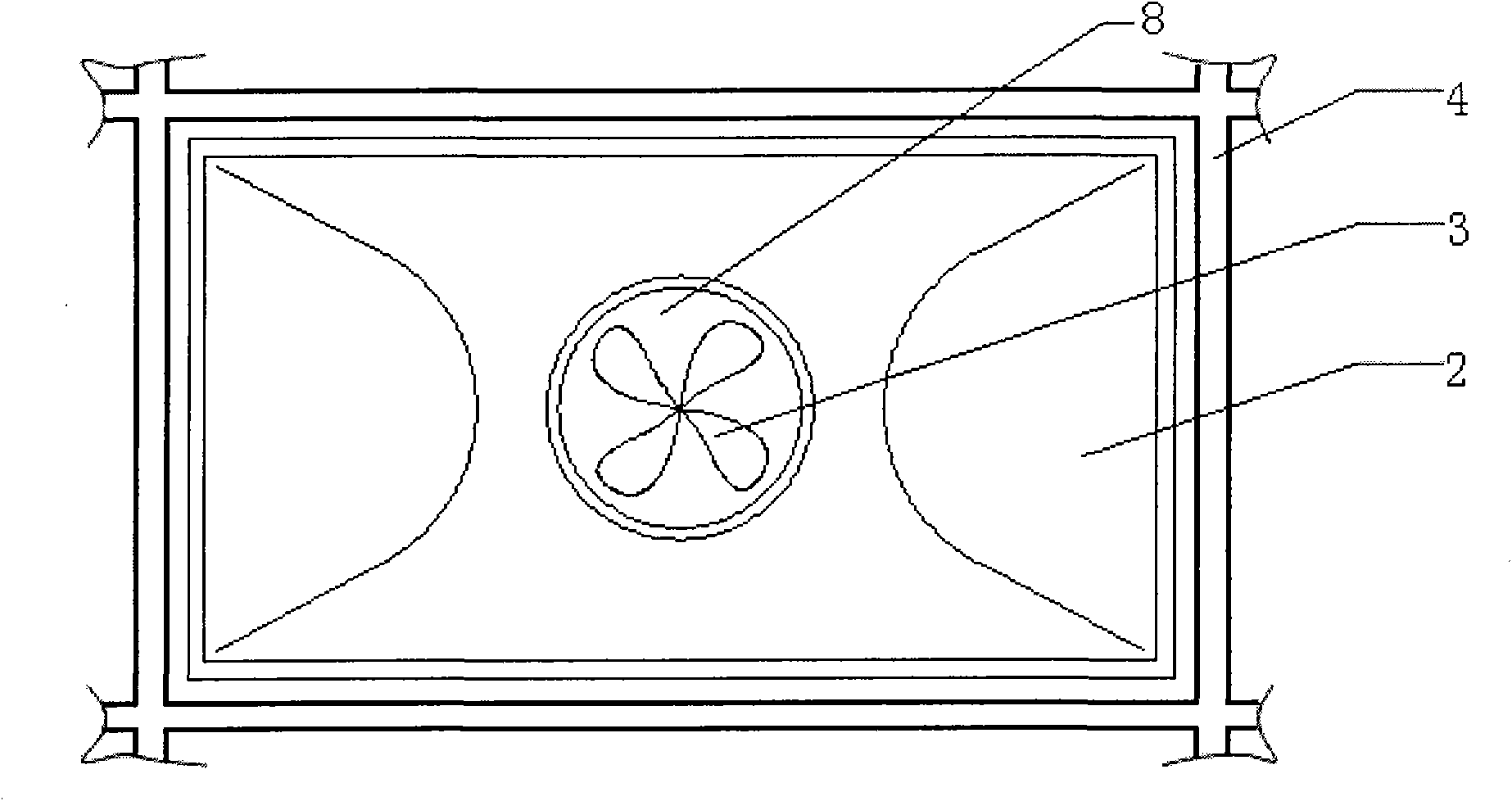

[0022] figure 1 It is a front view of an embodiment of the present invention; figure 2 for figure 1 Enlarged view of Part A of ; image 3 It is a top view of an embodiment of the present invention; Figure 4 It is a bottom view of an embodiment of the present invention.

[0023] Such as Figure 1 to Figure 4 As shown, the high-efficiency filter includes a casing 2, a filter element 1 and a steel frame 4, wherein an air inlet 8 is provided on the top of the casing, and the steel frame 4 and the outer wall of the filter element 1 form a U-shaped space that is fixedly connected. The material of the casing 2 It is plastic, and its shape is ∩ type, which can be molded by injection molding at one time. The lower end of the shell 2 is inserted into the U-shaped space formed by the steel frame 4 and the outer wall of the filter element 1.

[0024] In addition, an FFU fan 3 can also be arranged at the air inlet 8 to form a high-efficiency filter containing FFU to meet the special...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com