Compensation moving dolly for continuous casting steel moving machine

A technology of moving trolleys and moving steel, applied in the field of compensating mobile trolleys, can solve the problems of no compensation function for wire rope length changes, no buffering performance of disc springs, etc., and achieves the effect of novel structure and large amount of length compensation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

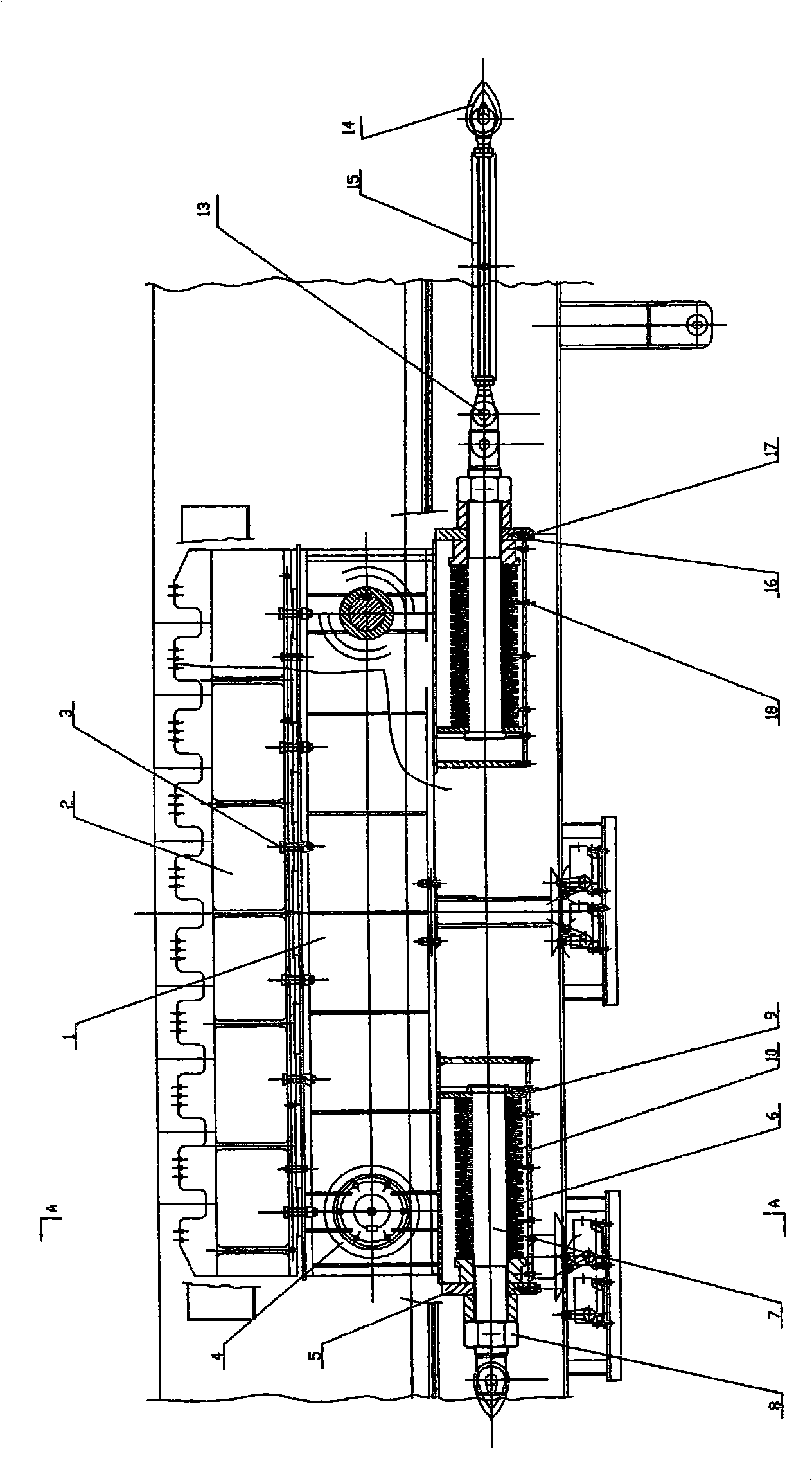

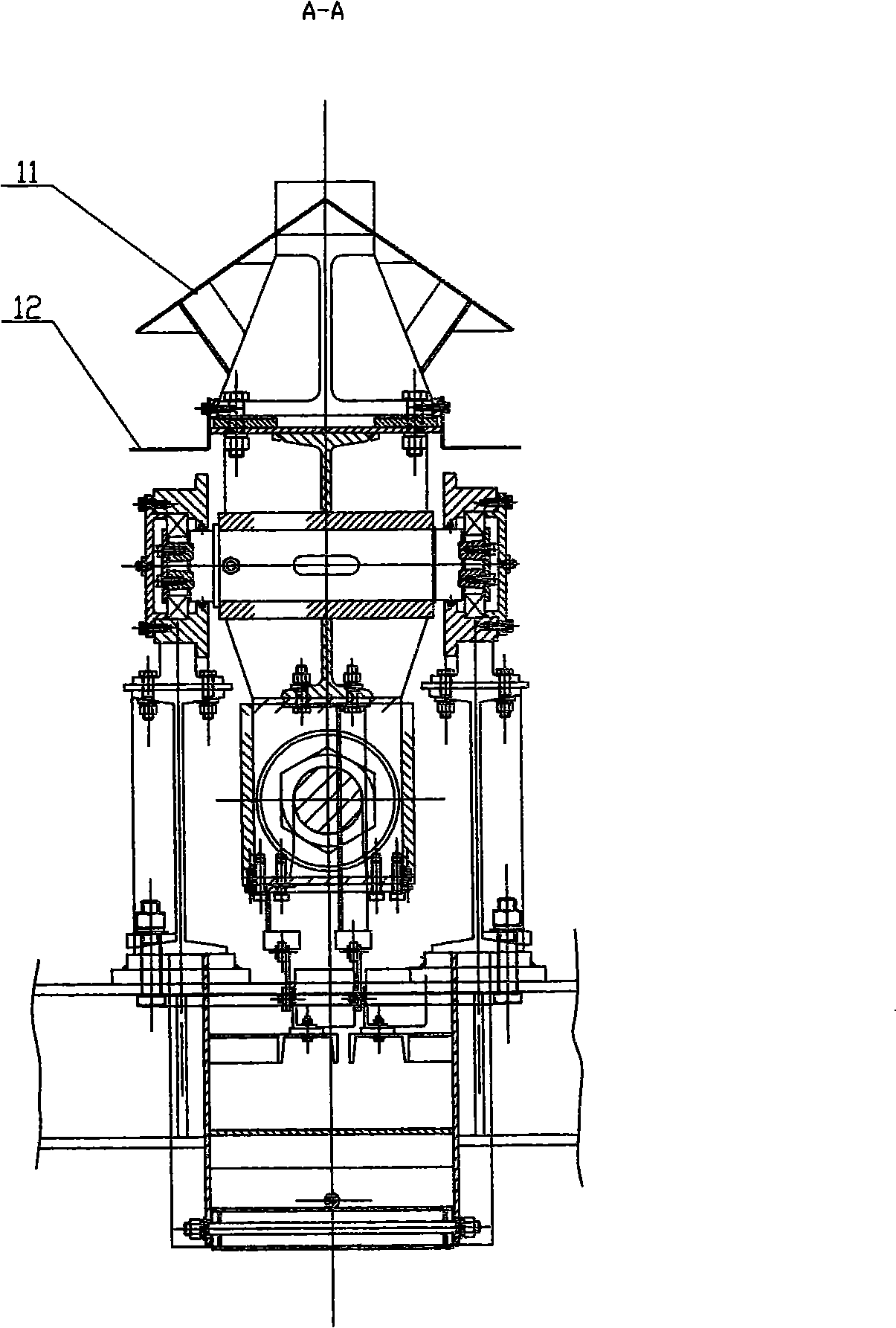

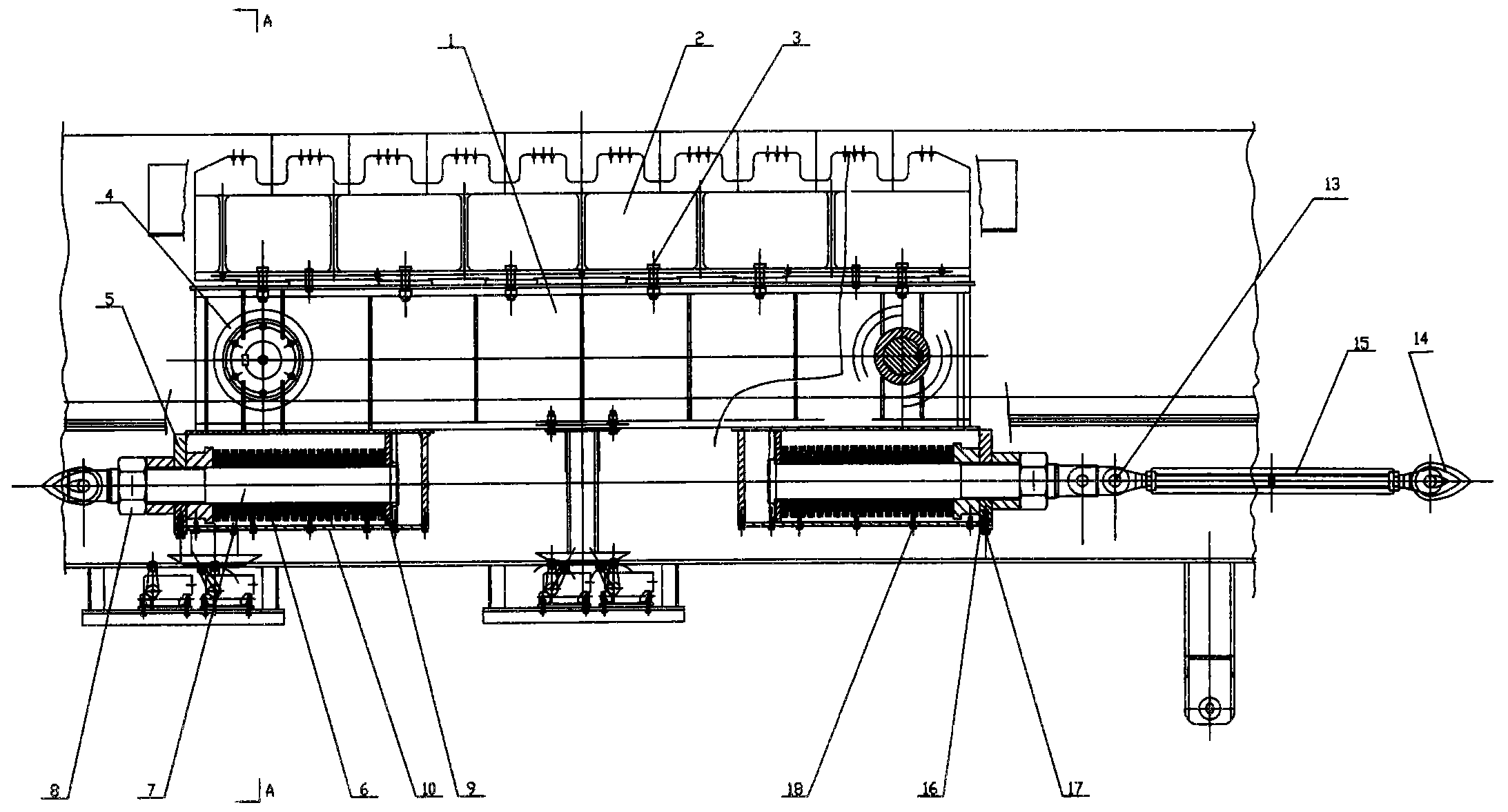

[0013] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0014] Such as figure 1 As shown, the joist 2 is fixed on the vehicle frame 1 with bolts 3; four wheels 4 are installed at both ends of the vehicle frame 1; A trumpet-shaped gap is opened on the steel plate to facilitate the installation of the guide rod 7; the disc spring group 6, guide rod 7 and guide plate 9 are installed in the guide box 5; , Φ30 pin shaft 13 and rope ring 14 are connected in series; use bolt 17 to fix the pressure plate 16 on the guide box 5, and support the guide rod 7 to prevent the guide rod from falling; use bolt 18 to connect the supporting plate 10 and the guide box 5 on the Together; the upper and lower heat shields 11,12 are fixed on the vehicle frame 1 with bolts. A wire rope shackle 15 is arranged betw...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com