Rotary-type self-latching safety braking device and working method thereof

A safety braking and wheel-type technology, applied in the direction of brake type, building structure support, building structure support, etc., can solve the problems of hidden safety hazards, many fault points, slow lifting or lowering process, etc., and achieve good sealing performance and control The effect of short moving distance and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

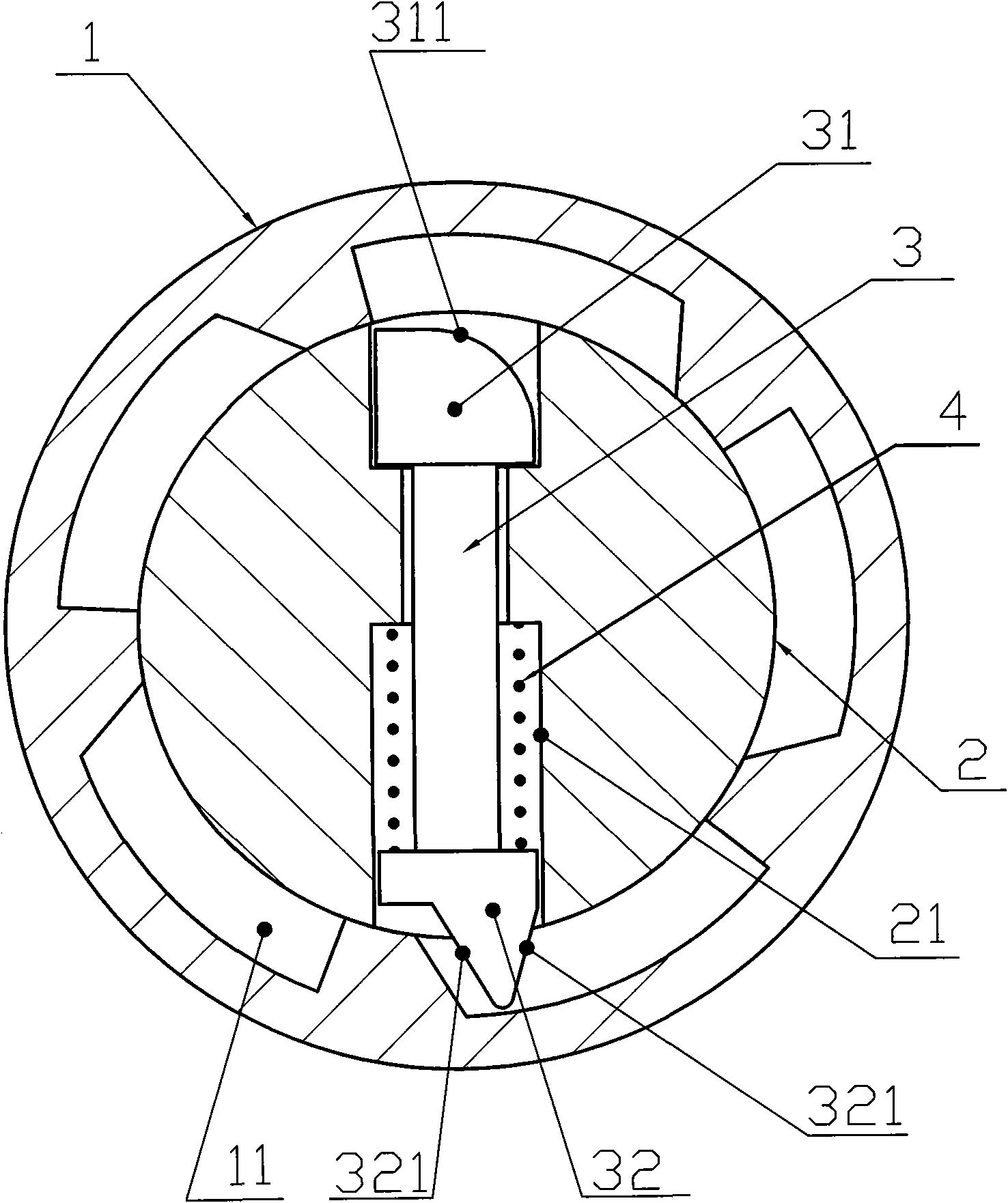

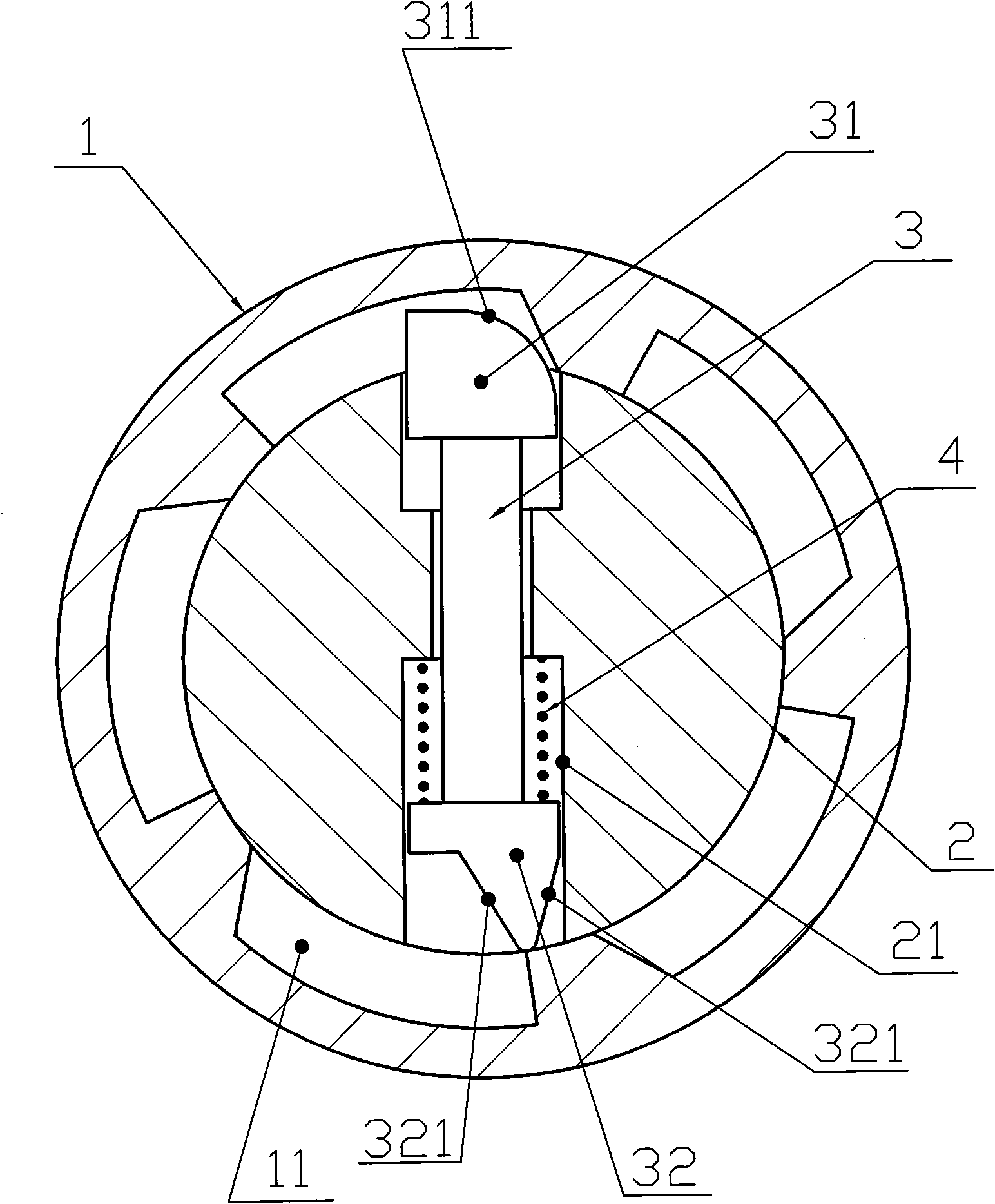

[0030] Such as figure 1 and figure 2 As shown, a wheel-type self-locking safety braking device provided in this example includes a wheel 1, a wheel shaft 2 that is arranged in the wheel 1 and rotates with the inner cylindrical surface of the wheel 1. The inner cylindrical surface of the wheel 1 is provided with a number of key grooves 11, and the wheel shaft 2 is provided with a chute 21 corresponding to the key groove 11 and radially penetrating, and the chute 21 is provided with a The movable pin key 3 of two-way sliding, described movable pin key 3 is provided with the pin key reset device 4 that can make this movable pin key 3 reset, and this reset device 4 can specifically be a compression spring, and the movable pin key 3 The length is equal to or slightly less than the sum of the diameter of the rotating shaft 2 and the depth of the key groove 11 . When the top 31 of the movable pin key 3 is pushed into the runner keyway 11, the tail end 32 will escape from the runne...

Embodiment 2

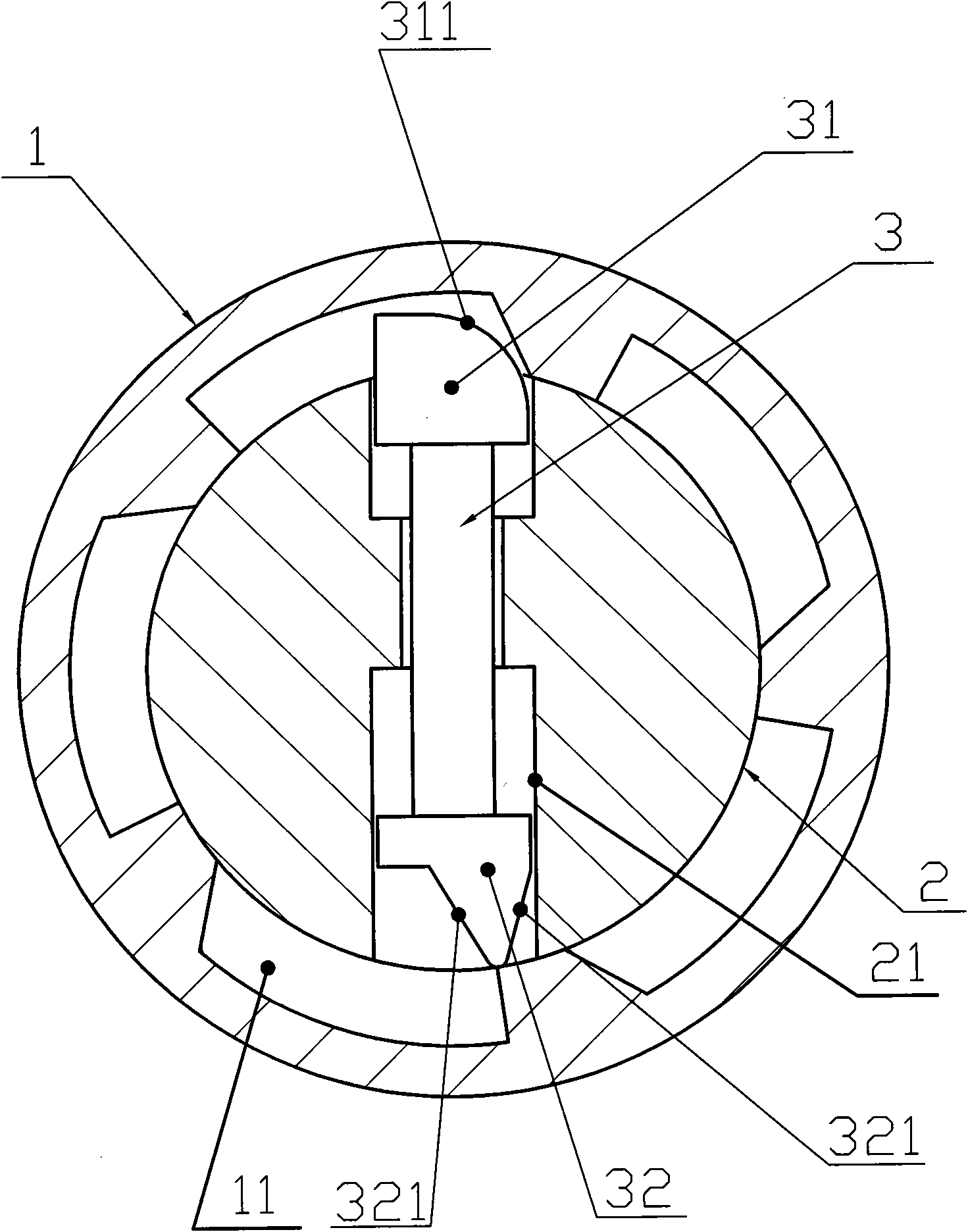

[0035] Such as image 3 As shown, this example is roughly the same as Embodiment 1, except that the pin key reset device 4 is omitted, the working position of the radial chute 21 of the wheel shaft 2 is set at a vertical position, and the top end of the movable pin key 3 31 is arranged on the top of described chute 21, and the tail end 32 of described movable pin key 3 is arranged on the bottom of described chute 21, utilizes the action field that the gravity of movable pin key 3 produces to promote its self reset.

[0036] Such as Figure 1 ~ Figure 3 As shown, the present invention also provides a working method of a wheel-type self-locking safety brake device involved in Embodiment 1 and Embodiment 2: when the wheel 1 rotates forward slowly, the side of the keyway 11 on the inner cylindrical surface of the wheel 1 Rib presses the slope 311 of the top 31 of the movable pin key 3, and the movable pin key 3 slides along the radial chute 21 of the wheel shaft 2 toward its tail...

Embodiment 3

[0039] refer to Figure 1 to Figure 5 , the present invention also provides an example of a wheel-type self-locking safety brake device applied in the field of attached lifting scaffolding, that is, a wheel anti-falling device of an attached lifting scaffold, which includes a guide rail 5 and a guide seat 6, The guide rail 5 is connected with the guide seat 6 by a sliding sleeve, the guide rail 5 is provided with cross bars 51 at intervals, and the guide seat 5 is provided with a runner 1 that can rotate and engage with the cross bar 51; A kind of rotating wheel type self-locking safety braking device as mentioned above is set on the hub 12.

[0040] The working method of the runner anti-falling device of an attached lifting scaffold provided by the present invention is as follows: when the scaffold is slowly lifted, the runner 1 engages with the spaced cross bar 51 set on the guide rail 5 and rotates forward slowly; the scaffold slowly descends At the same time, the running ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com