Reflective cup for LED lamp

A technology of LED lamps and reflector cups, applied in the field of reflector cups, can solve the problems of not being able to fully utilize light energy, unsuitable, unsuitable for lighting systems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings.

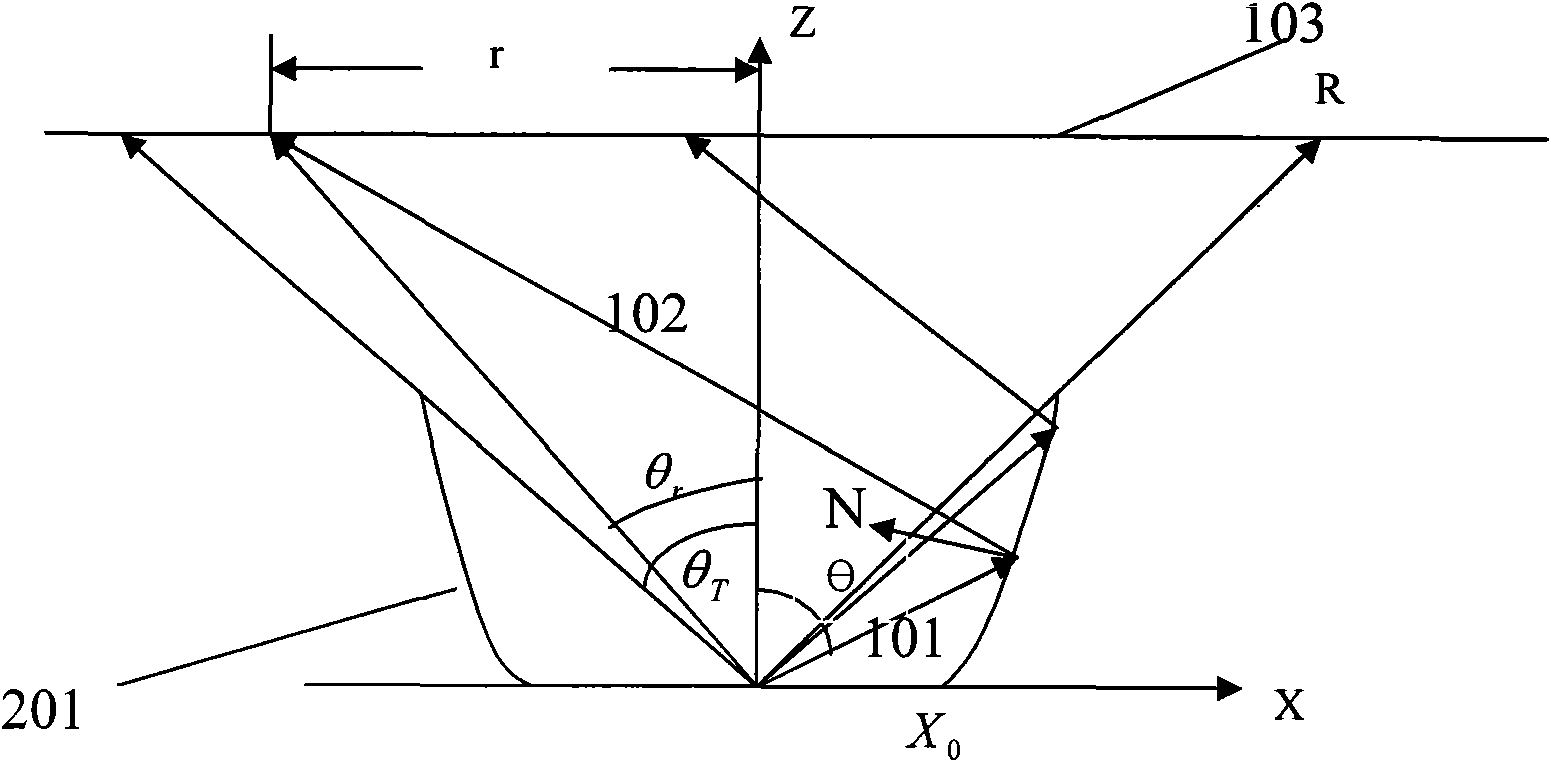

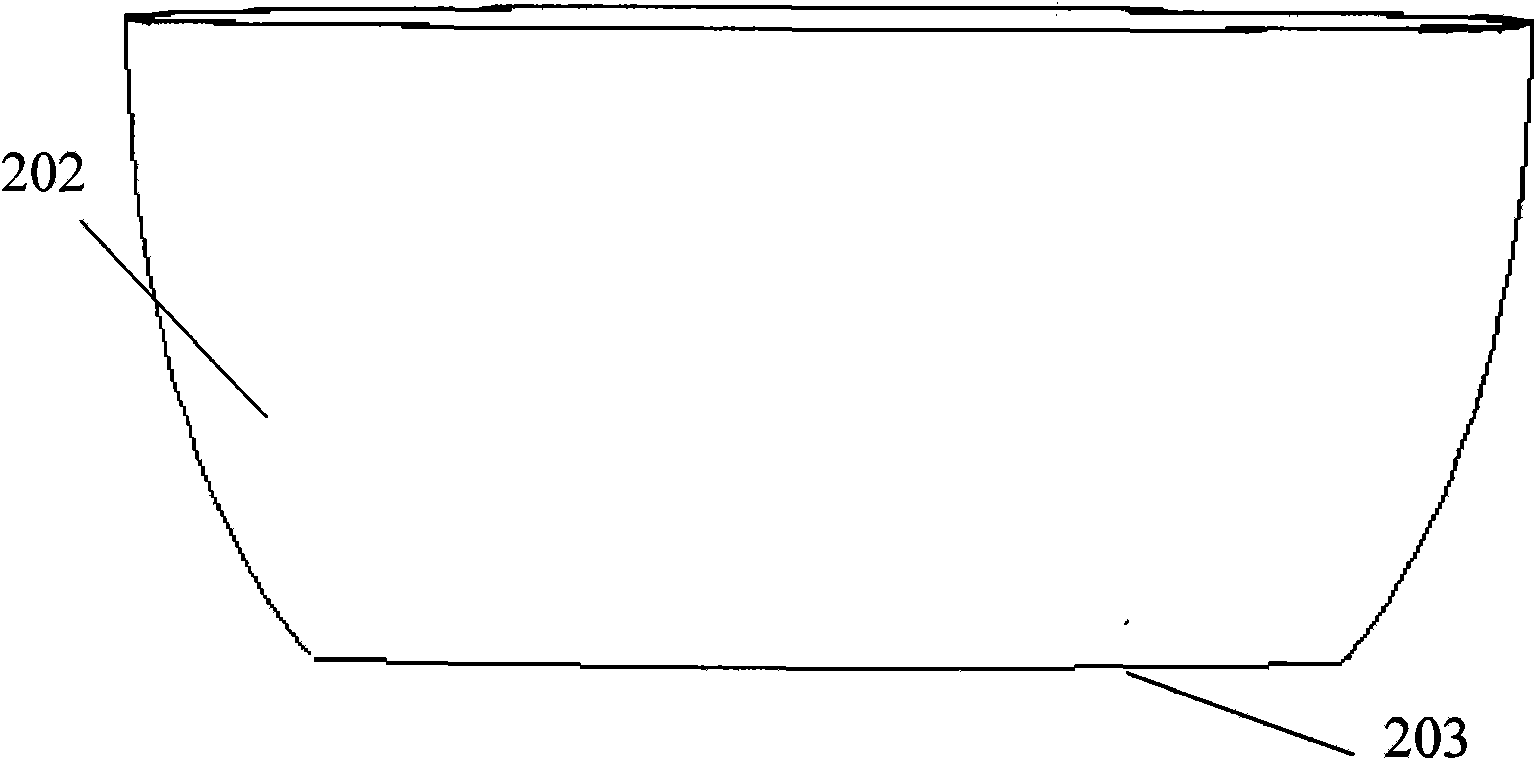

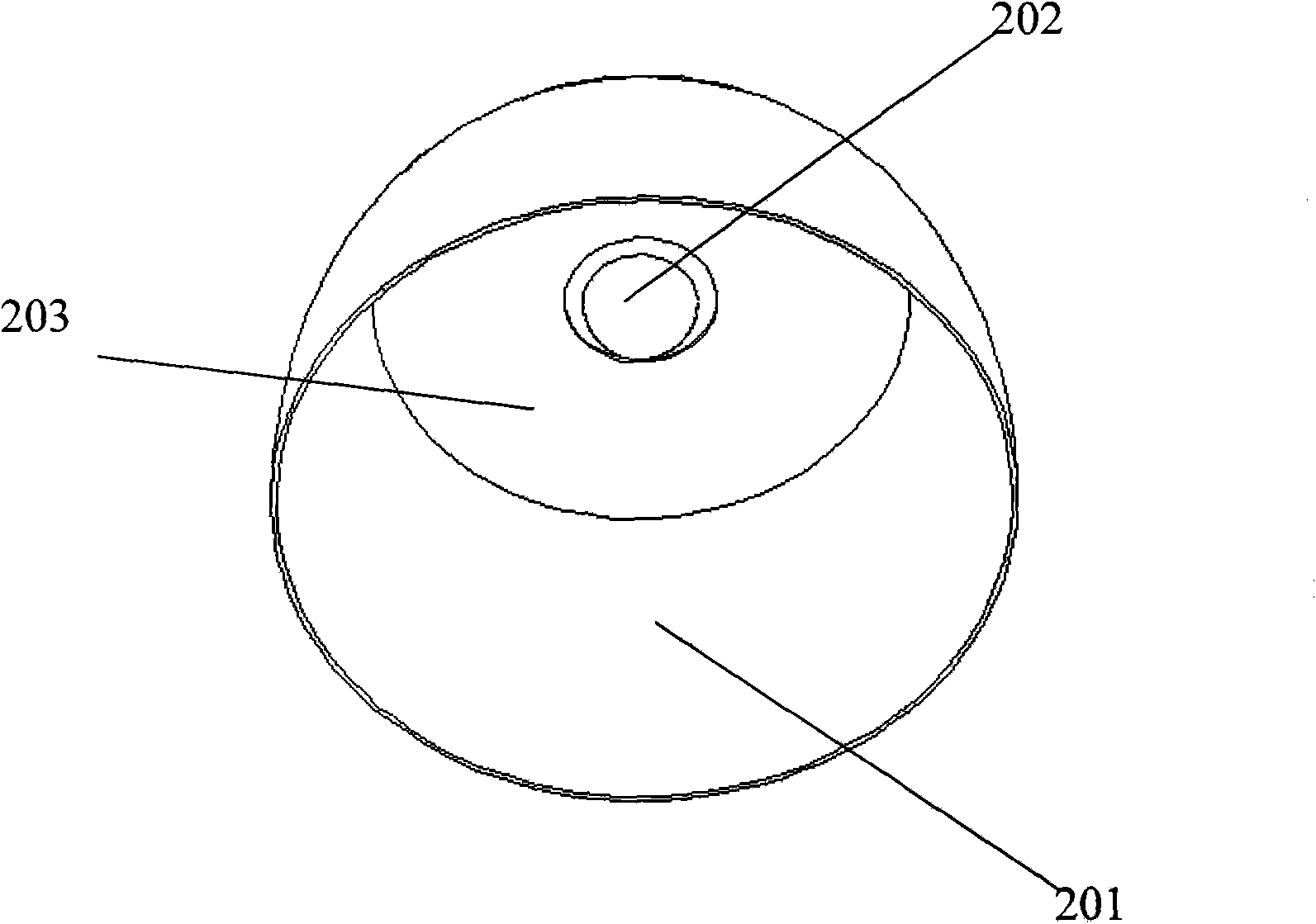

[0053] The reflective cup used for LED lamps includes a reflective surface 201 and an annular bottom surface 203. The LED 202 is placed in the center of the bottom surface. Part of the light from the LED is directly emitted from the opening of the reflective cup. This part of the light reaches the target plane to form an initial lighting surface. The reflective surface of the cup reflects the rest of the light to the initial lighting surface, so that the energy of the two parts of light is superimposed to form a uniform lighting surface. The reflective surface of the reflective cup is a free-form surface, and the shape of the free-form surface is determined by the following method.

[0054] In this embodiment, the curve is determined through the following steps:

[0055] The light source adopts Lambertian LED, that is, the light intensit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com