Membrane-packaged rectangular stranded conductor and manufacture method

A wire and rectangular technology, which is applied in the field of wire and preparation for dry-type air-core smoothing reactor coils, can solve problems such as large eddy current loss, burnt coils, and unsafe system operation, and achieve good short-circuit resistance and strong short-circuit resistance , The effect of compact wire structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

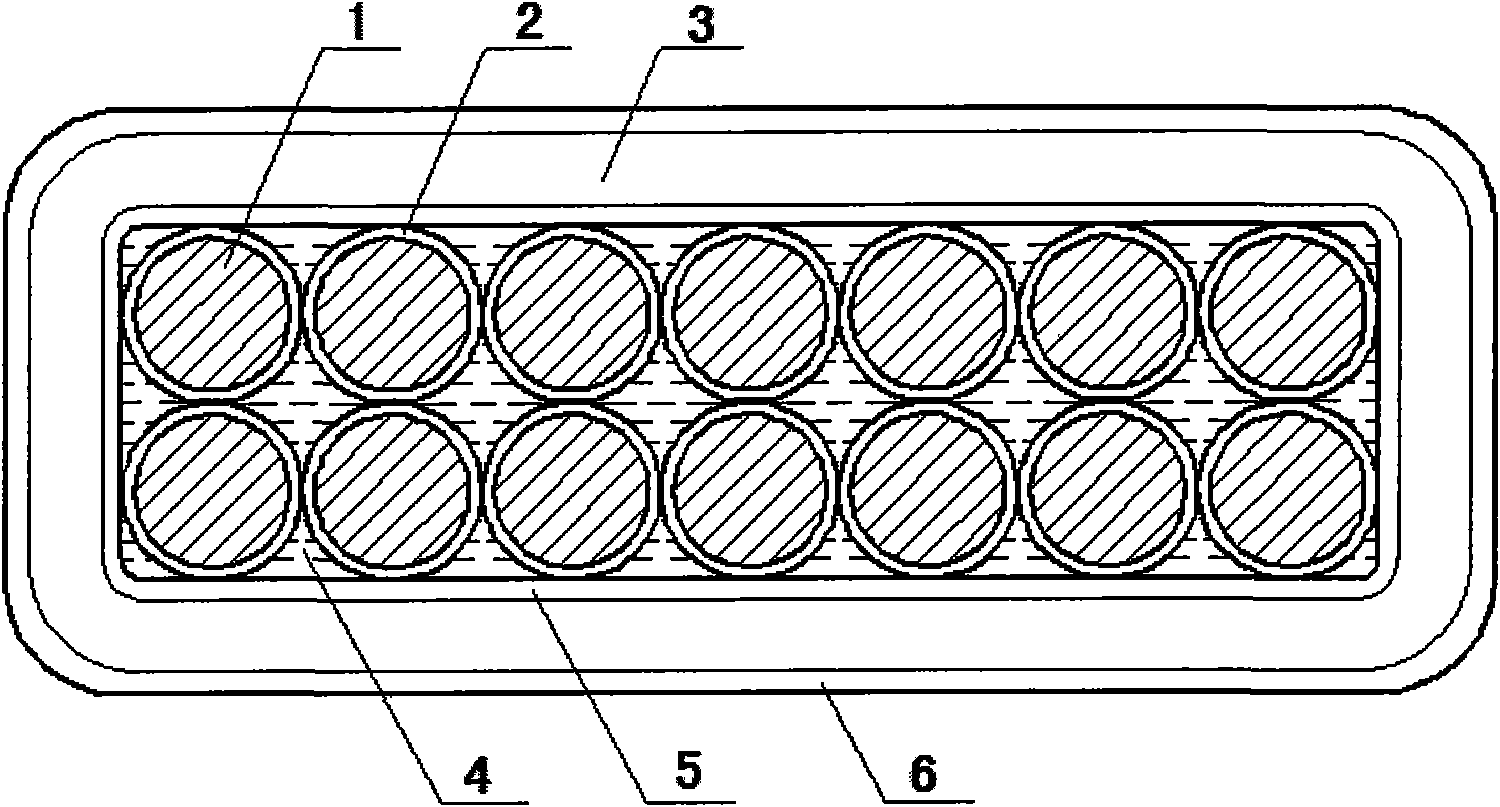

[0025] Such as figure 1 As shown, the film-wrapped rectangular stranded wire has a rectangular cross-section and is formed by twisting two layers of multiple round aluminum wires 1 . The outer diameter of each round aluminum wire is covered with a wire coating 2, and the length and resistance of each wire are basically equal; the gap between the twisted single round aluminum wires is filled with thermoplastic resin glue 4 of the same heat-resistant grade, and thermoplastic resin glue 4 Epoxy resin glue can be used, and the rectangular stranded wire filled with epoxy resin glue is wrapped with glue insulation 5 first, then wrapping insulation 3, and finally wrapping polyester non-woven fabric 6 outside the wrapping insulation 3.

[0026] The preparation method of the film bag rectangular stranded wire of the present invention comprises the following steps:

[0027] 1) Wrap a single round aluminum wire 1 with polyester film or high-temperature-resistant insulating varnish or hi...

Embodiment 2

[0035] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

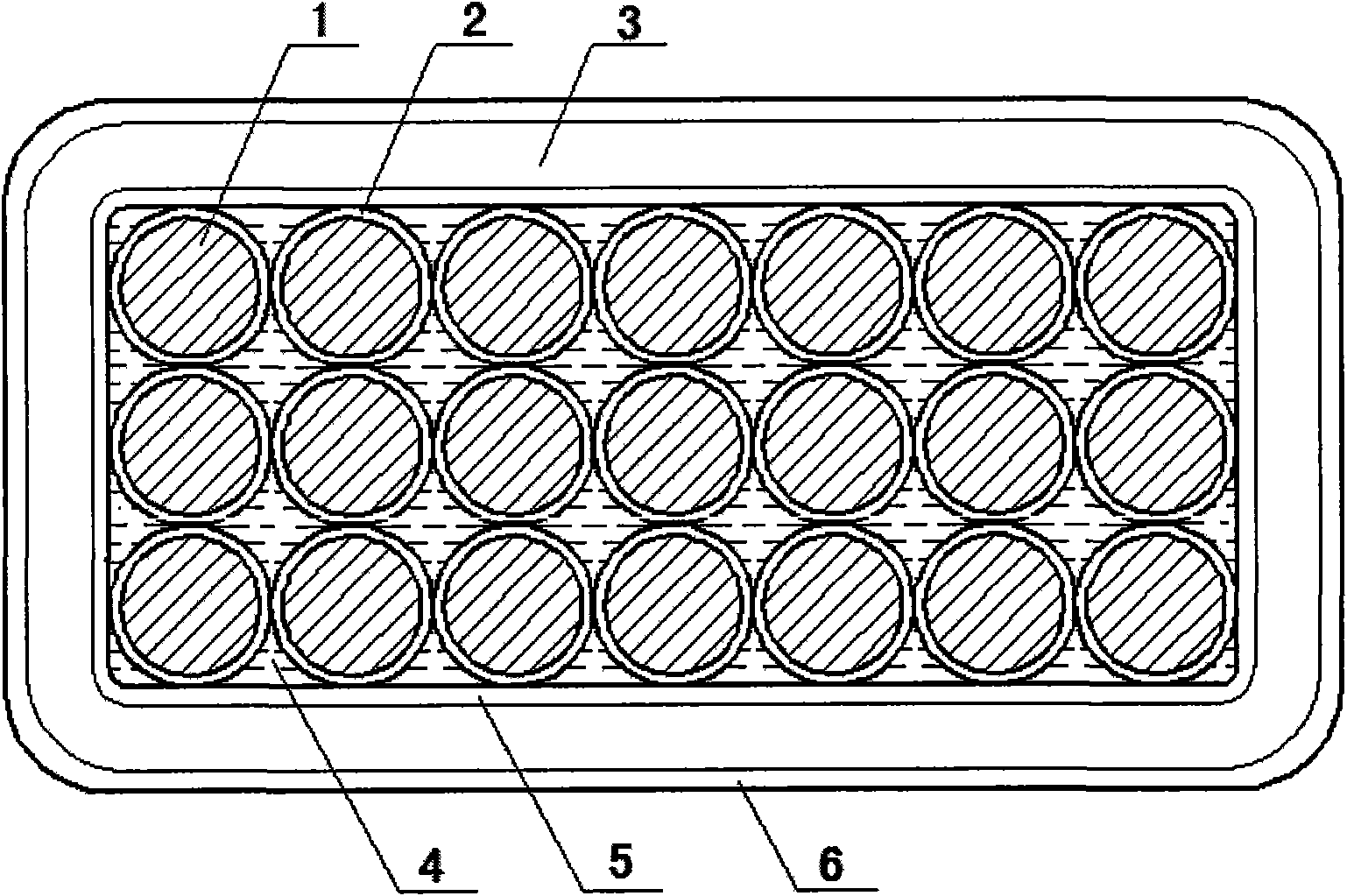

[0036] Such as figure 2 As shown, the film-wrapped rectangular stranded wire has a rectangular cross-section and is formed by twisting three layers of multiple round aluminum wires 1 . The outer diameter of each round aluminum wire is covered with a wire coating 2, and the length and resistance of each wire are basically equal; the gap between the twisted single round aluminum wires is filled with thermoplastic resin glue 4 of the same heat-resistant grade, and thermoplastic resin glue 4 Epoxy resin glue can be used, and the rectangular stranded wire filled with epoxy resin glue is wrapped with glue insulation 5 first, then wrapping insulation 3, and finally wrapping polyester non-woven fabric 6 outside the wrapping insulation 3.

[0037] The preparation method of the film bag rectangular stranded wire of the present invention comprises the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com