Method for reducing exhausted carbon dioxide by using microalgae

A technology of carbon dioxide and microalgae, applied in chemical instruments and methods, separation methods, and separation of dispersed particles, can solve the problems of reducing the rate of microalgae to fix CO2, complex structure of photobioreactor, and low efficiency of gas-liquid mixing. Achieve the effect of improving gas-liquid mixing efficiency and circulation degree, increasing fixed speed, and occupying a small area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

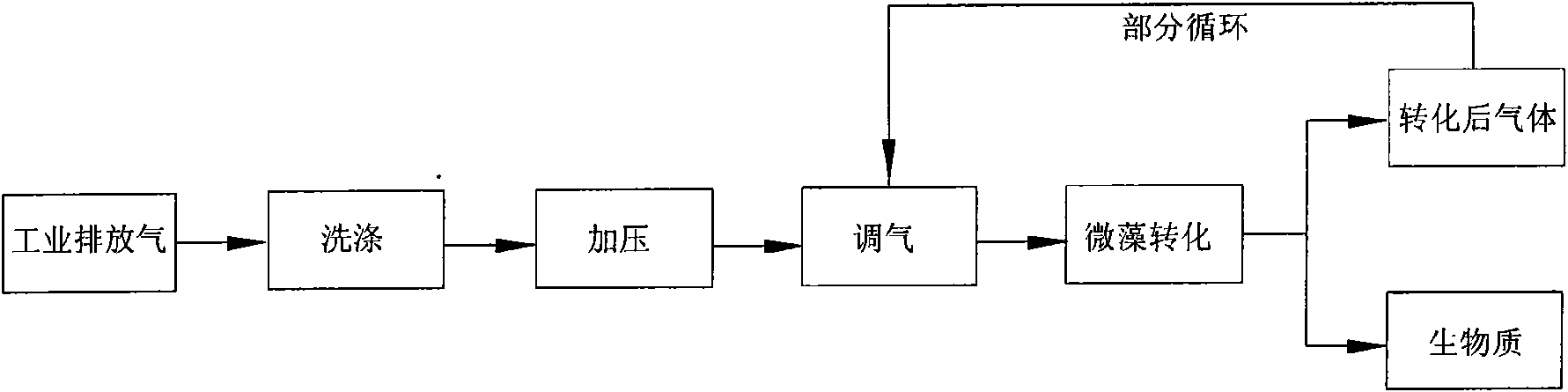

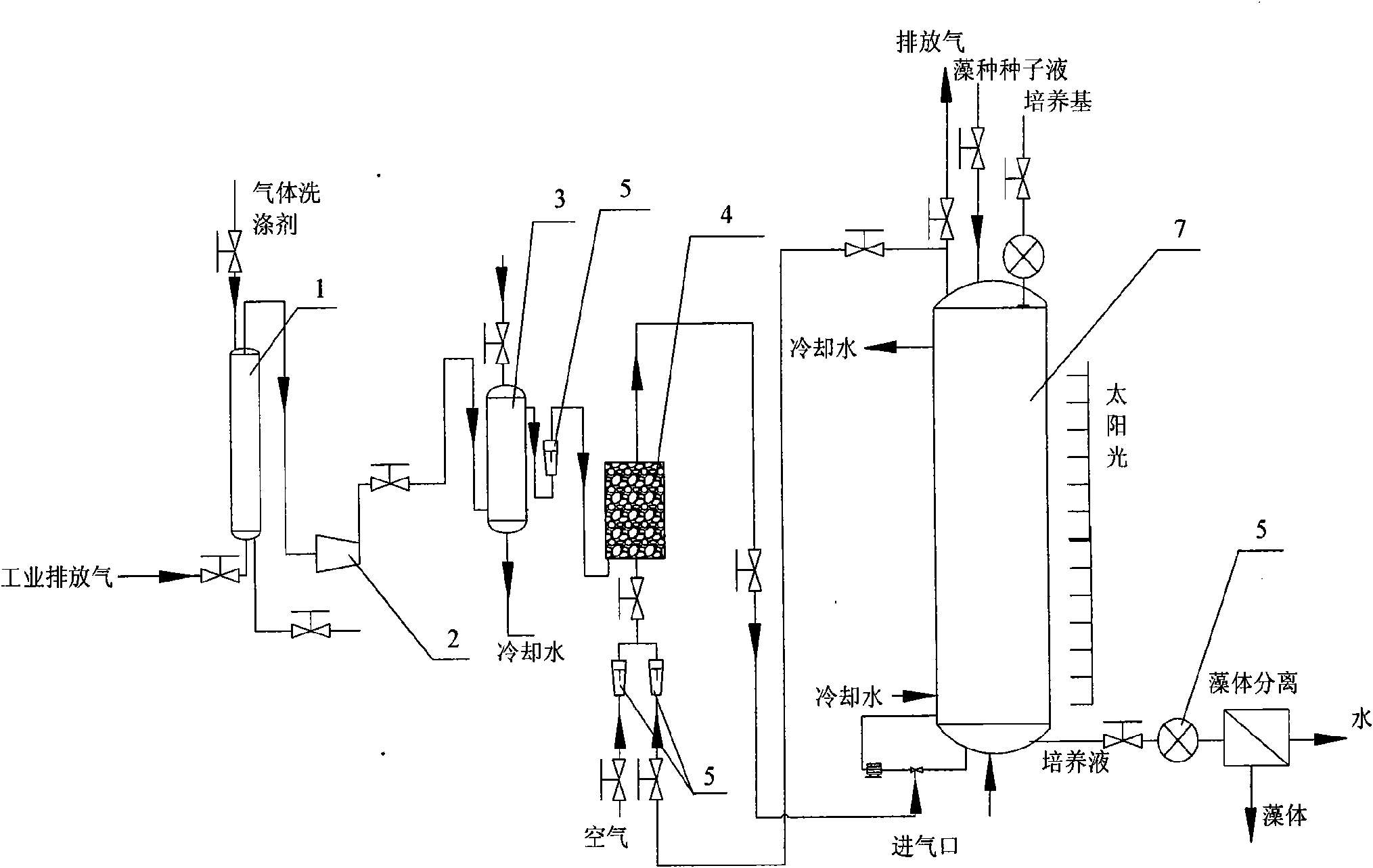

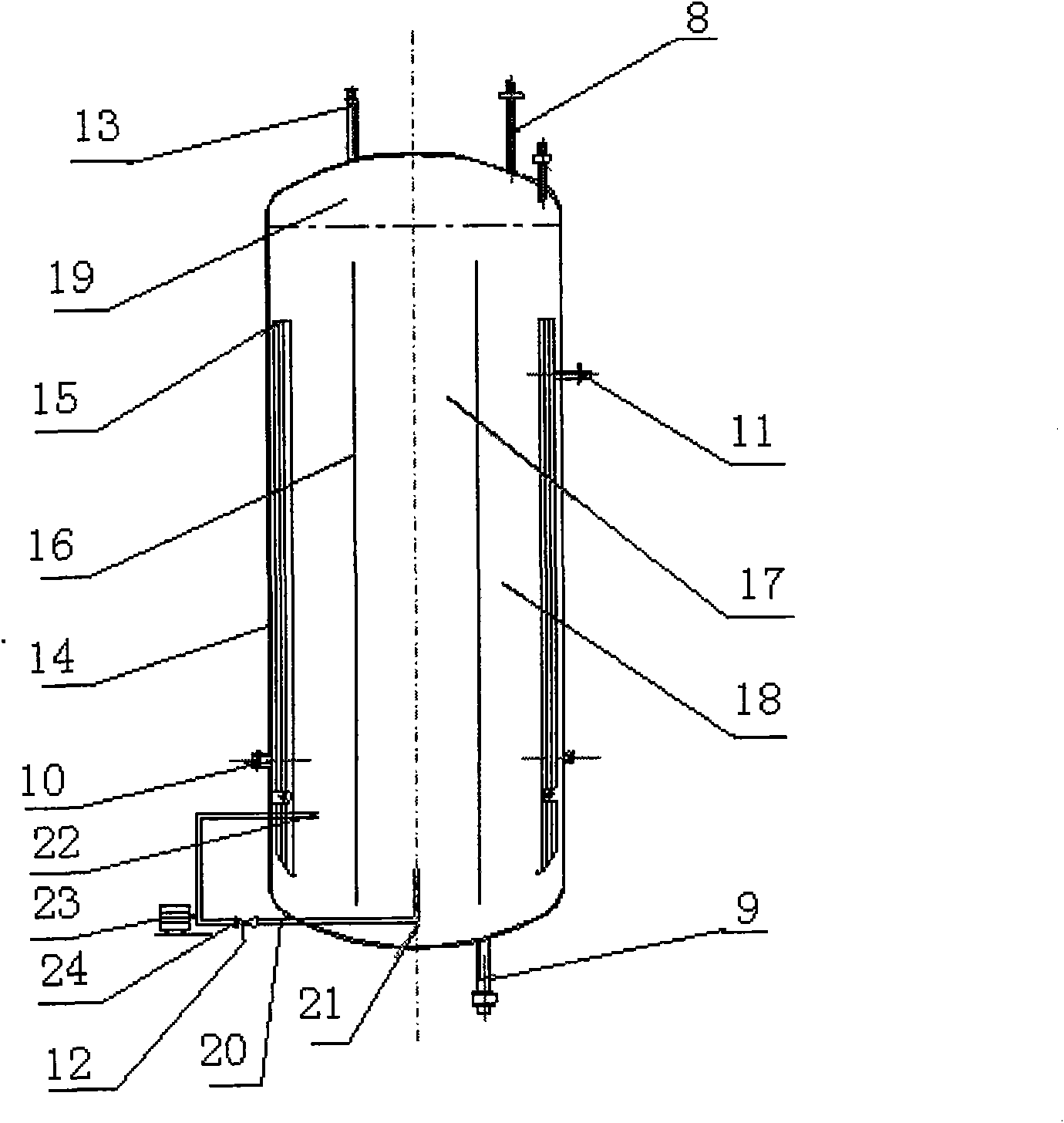

[0035] Embodiment 1: refer to figure 1 , figure 2 , in this embodiment, the industrial exhaust gas adopts CO 2 For the flue gas with a concentration of about 25%, the flue gas is first passed through the scrubber 1 and added with gas scrubbers to remove fine particles, other solid substances, and some acid gases, other organic and inorganic substances in the flue gas, so that Dust content reduced to 2mg / Nm 3 Afterwards, pressurize to 0.1-2.3MPa through compressor 2, then cool the gas temperature to 20-30°C through cooler 3, the cooled gas passes through flow meter 5 and then is sent to gas filter regulator 4, and the supplementary gas passes through Part of the recycled converted gas discharged from the ascending photobioreactor 7 makes the CO 2 The concentration is reduced to 15% to 20%, and the gas to be treated that meets the needs of microalgae is obtained, and then the gas to be treated is sent into the airlift photobioreactor 7, and after entering the glass tank 14 o...

Embodiment 2

[0040] Example 2: In the gas adjustment step, the air is directly used to adjust the CO in the gas 2 Concentration, described microalga selects Scenedesmus obliquus (Scenedesmus obliquus) for use, all the other are the same as embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com