Multifunctional power head device for automatic hydraulic tubing cutting machine tools

A technology for cutting machine tools and hydraulic pipes, applied in the field of automatic hydraulic pipe cutting machines, can solve the problems of high processing cost, easy damage of sawing tools, poor flatness of end faces, etc., and achieves good flatness, improved efficiency and shortened processing. effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

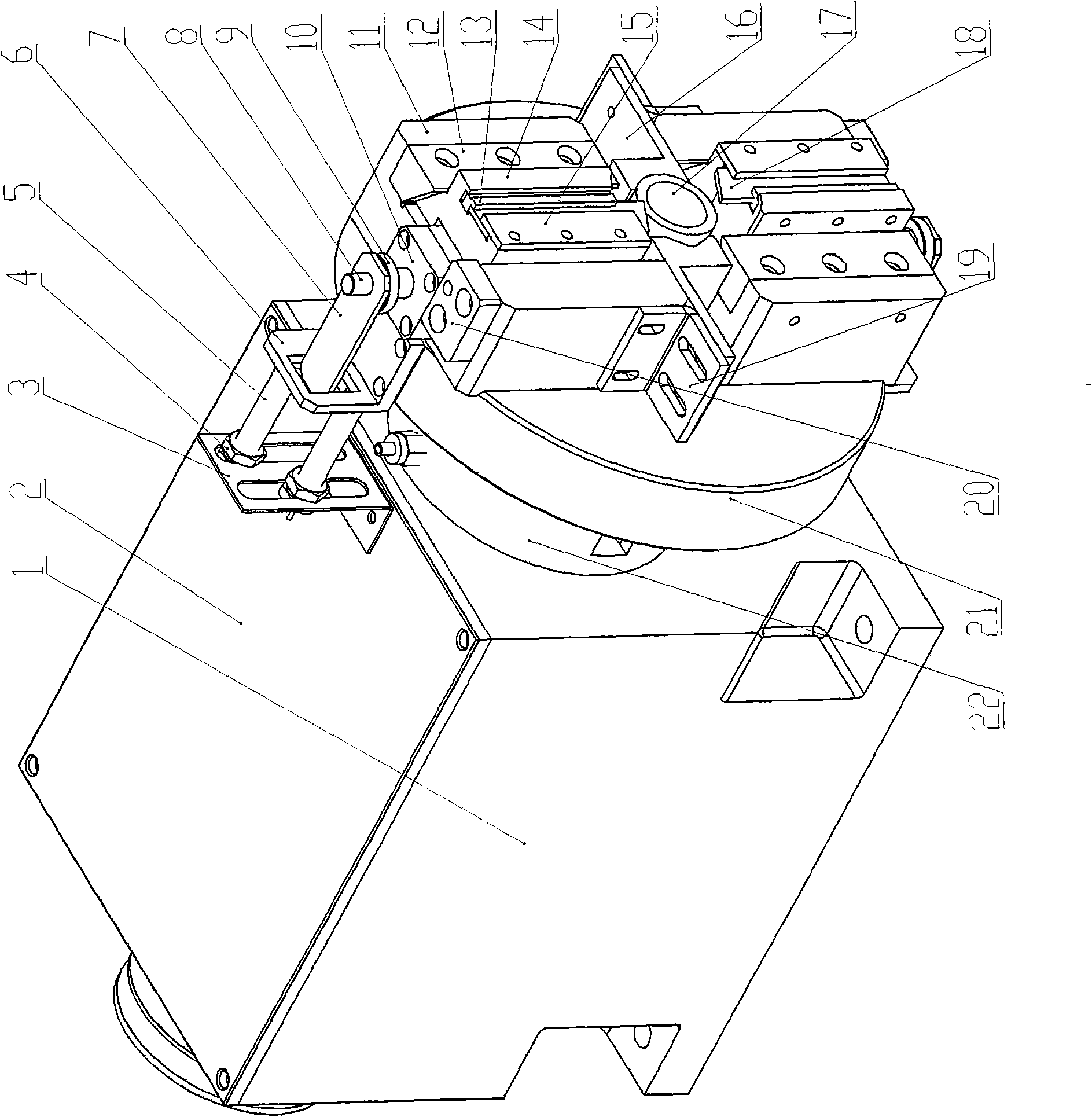

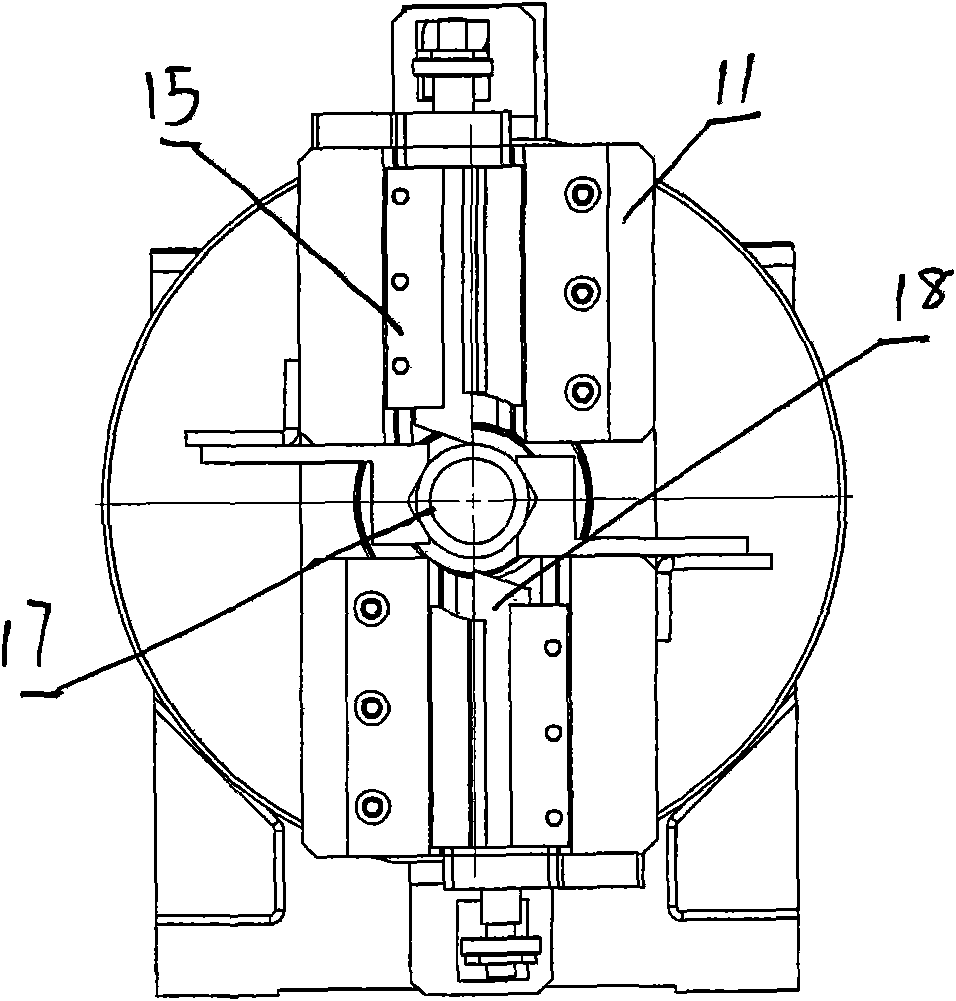

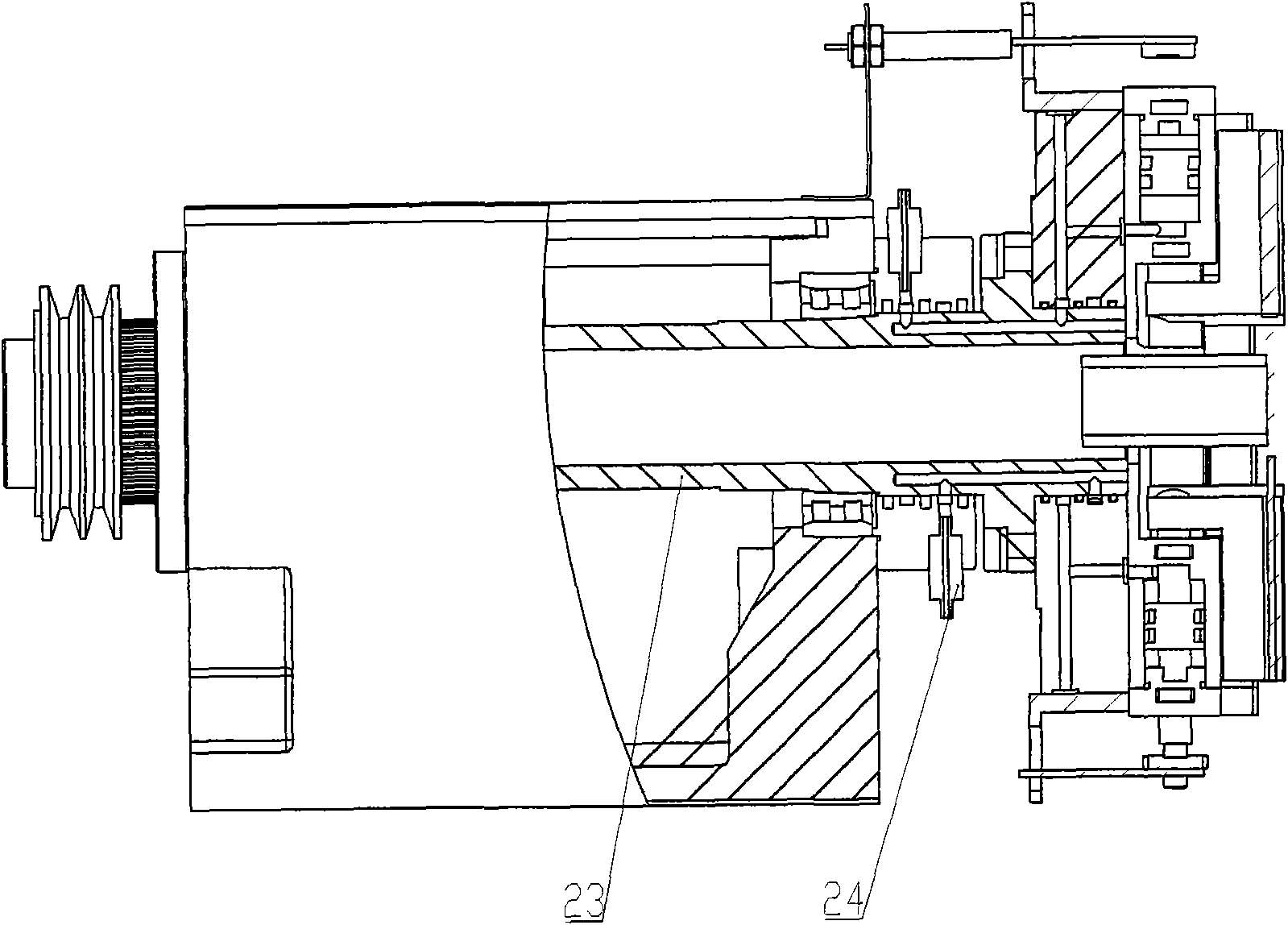

[0013] Such as Figure 1-Figure 5 As shown, the multifunctional power head device of the automatic hydraulic pipe material cutting machine tool is a device that simultaneously achieves the three processes of cutting off the workpiece 17, cutting the end face, and chamfering. It includes stroke protection block 6, piston rod 8, stroke pad 9, oil cylinder cover 10, lower guide rail 11, guide rail bead 12, upper pressure knife plate 13, guide rail 14, pressure knife plate 15, workpiece guide block 16, workpiece guide seat 19 , flange 21, front end cover 22, main shaft 23, and various nuts and various sealing rings connected to them; Turning tool 18 is fixed at guide rail 14 by upper pressure knife plate 13, pressure knife plate 15. The workpiece 17 is guided by the workpiece guide block 16 and the workpiece guide seat 19. Flange 21, front end cover 22, main shaft 23 are all special parts, all have oil circuit in the parts, and hydraulic oil realizes the motion of oil cylinder b...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap