Brazing machine for electric heating composite pan bottom

A brazing machine and electric heating technology, applied in electric heating devices, induction heating, induction heating control and other directions, can solve the problems of uneven heating and brazing temperature, poor welding quality at the bottom of the pot, and high skin effect, so as to improve the quality of brazing. quality, guarantee the quality of brazing, guarantee the effect of brazing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

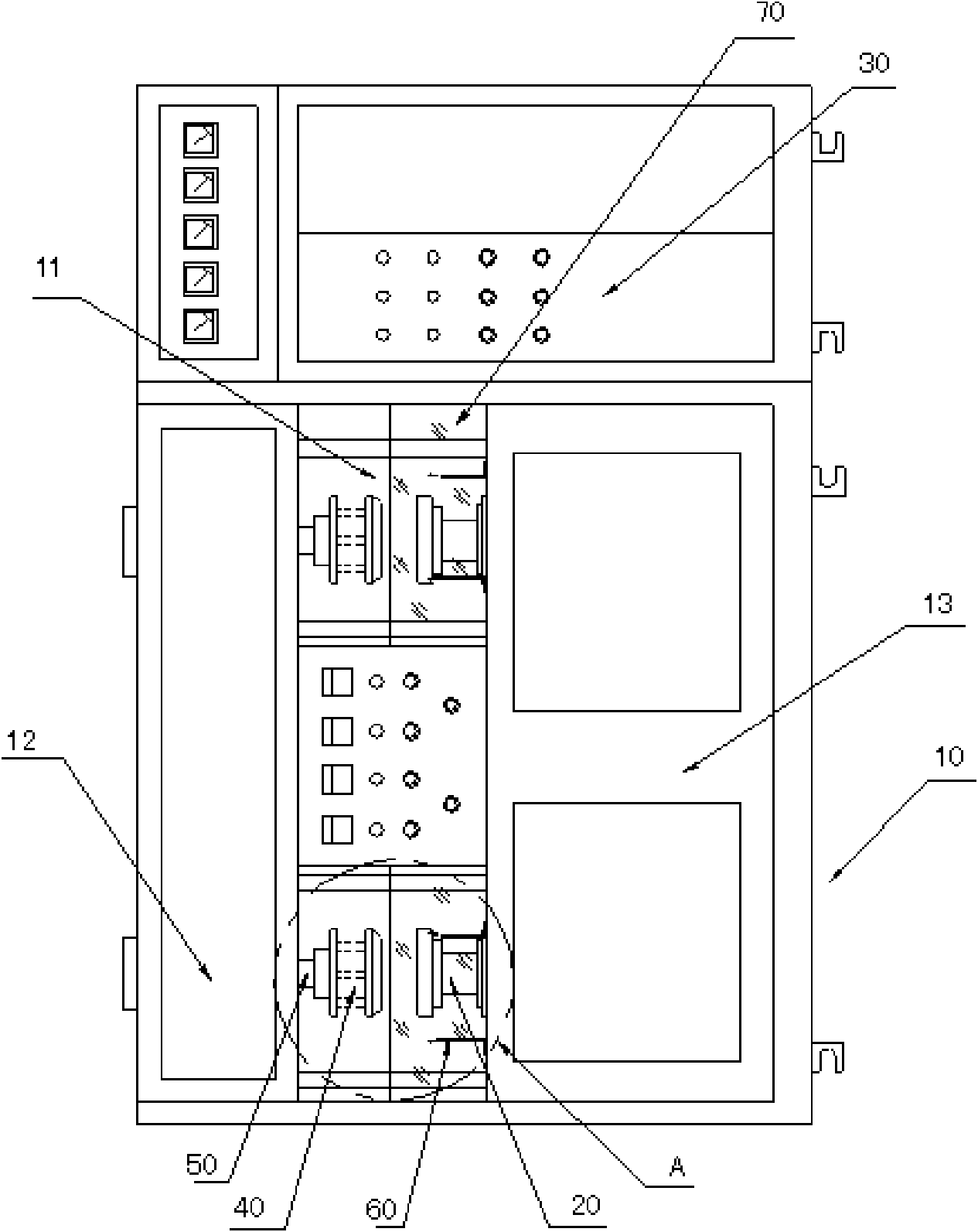

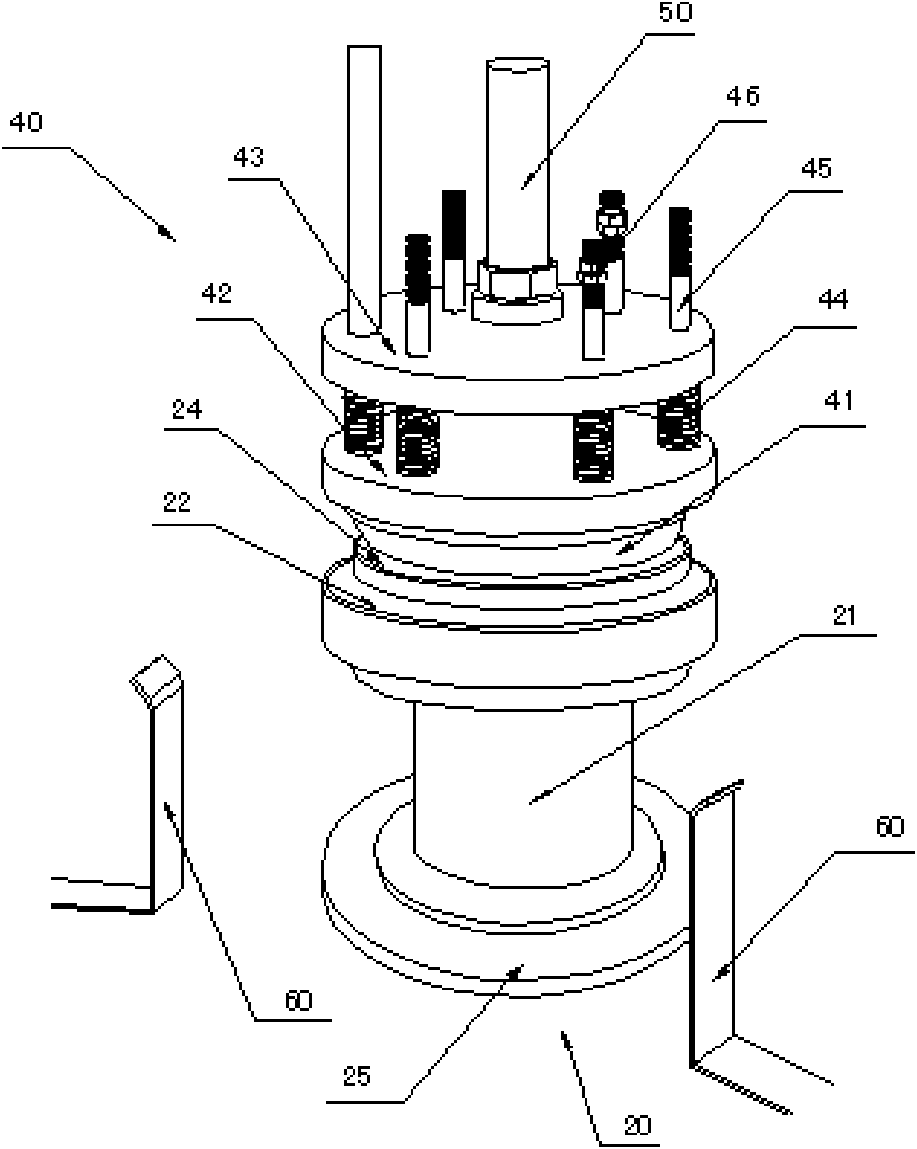

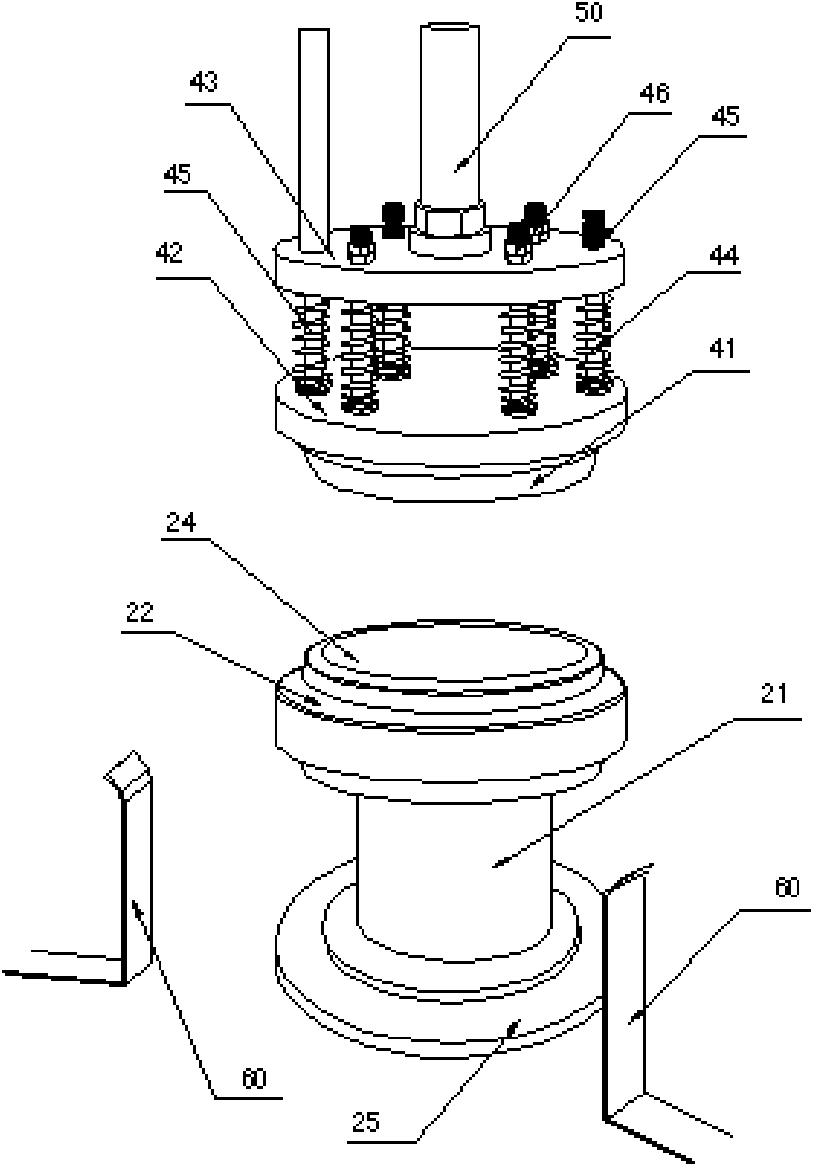

[0024] figure 1 , figure 2 In the shown embodiment, a kind of brazing machine for electric heating compound pot bottom comprises frame 10 and welding platform 11 arranged on the frame, and the upper working frame 12 of welding platform is connected with the pressing bar 50 that can move up and down , the lower end of the pressing rod 50 is connected to the pressing plate device 40, and the intermediate frequency induction heating power supply control device 30 is provided in the frame 10 to provide the intermediate frequency induction heating power supply for the brazing machine. Between the lower working frame 13 of the welding table and the platen device 40, a fixed support seat 20 is correspondingly installed, and the supporting seat 20 is fastened on the lower working frame 13 of the welding table through its foot seat 25, and the intermediate frequency is connected to the upper end of the supporting seat 20. Heating head 22, a heating process plate 24 is connected above...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com