Brazing machine for electric heating composite pan bottom

A brazing machine and electric heating technology, applied in electric heating devices, induction heating, induction heating control and other directions, can solve the problems of uneven heating and brazing temperature, poor welding quality at the bottom of the pot, and high skin effect, so as to improve the quality of brazing. quality, guarantee the quality of brazing, guarantee the effect of brazing temperature

Inactive Publication Date: 2011-01-05

王新田

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The present invention aims to solve the problem of high skin effect and concentrated heating area on the induction coil part of the external heat brazing used by the existing high-frequency induction heating brazing machine when brazing the bottom of cookware such as composite stainless steel pots, pots, and pots. The local temperature is high, and the heating and brazing temperature is correspondingly uneven, which leads to poor welding quality of the bottom of the pot and the occurrence of false welding. A medium-frequency induction heating device and an internal heating brazing method are provided to directly heat the bottom of the pot, which can ensure that the center Brazing machine for electric heating composite pot bottom with uniform heating and brazing temperature

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

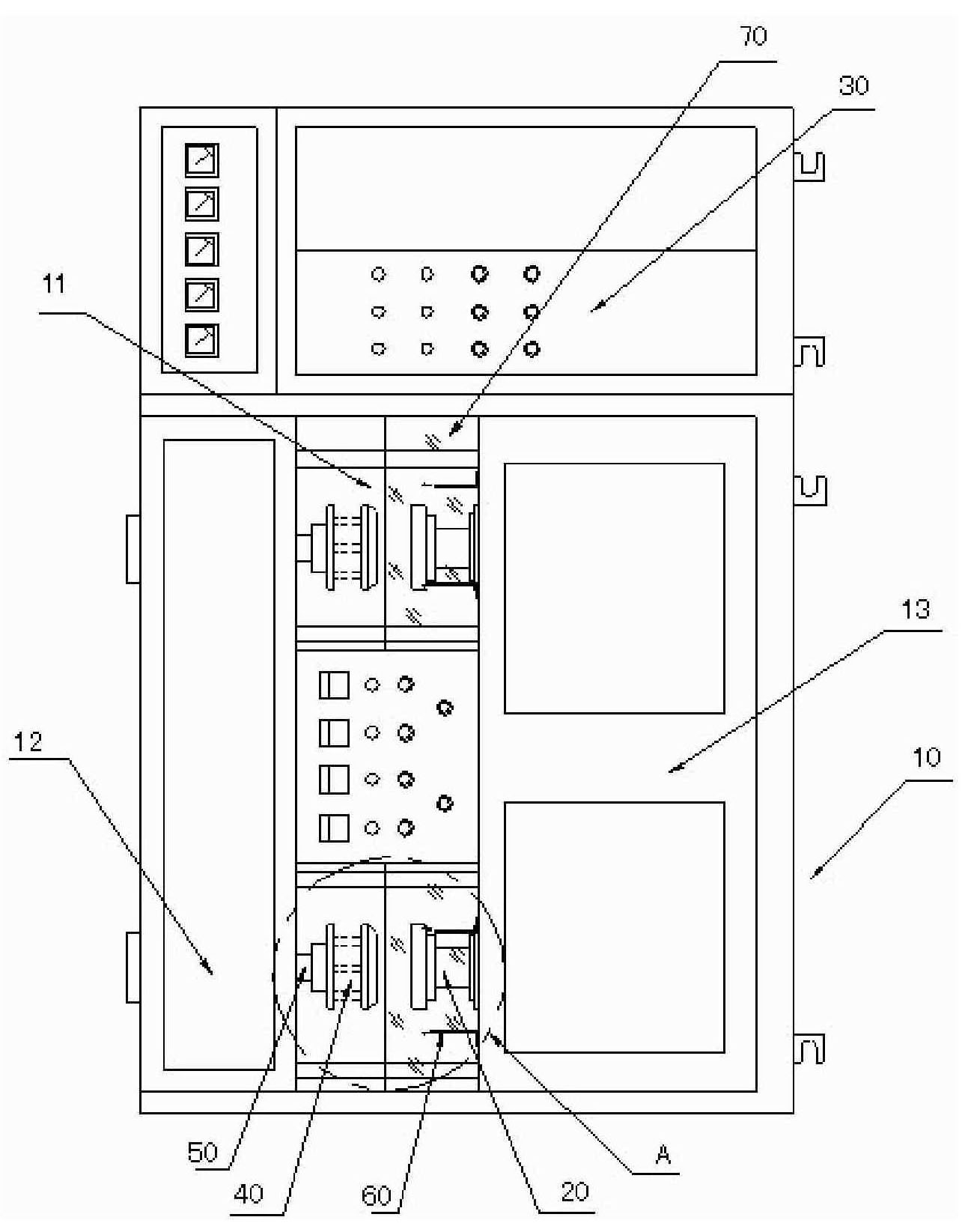

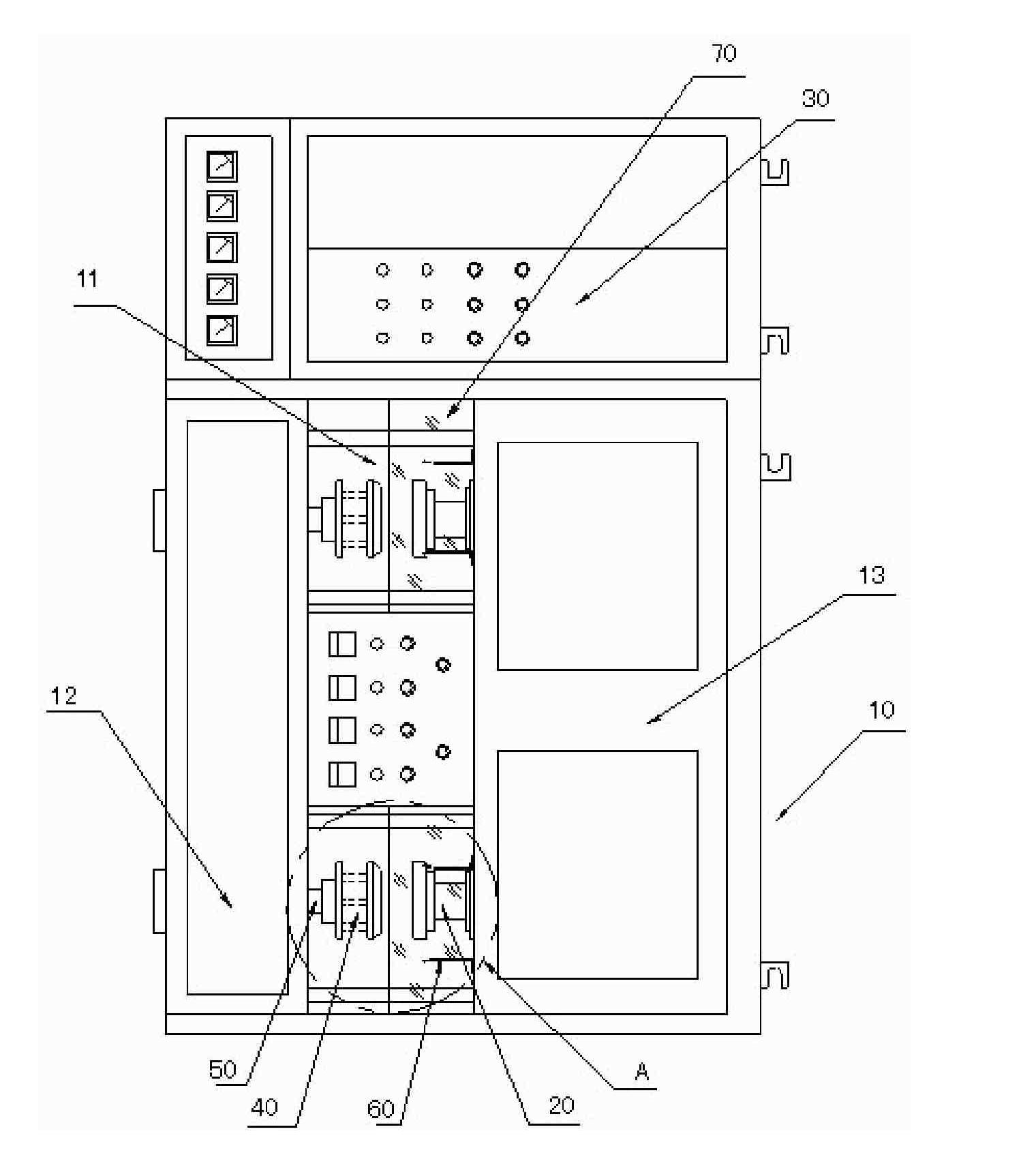

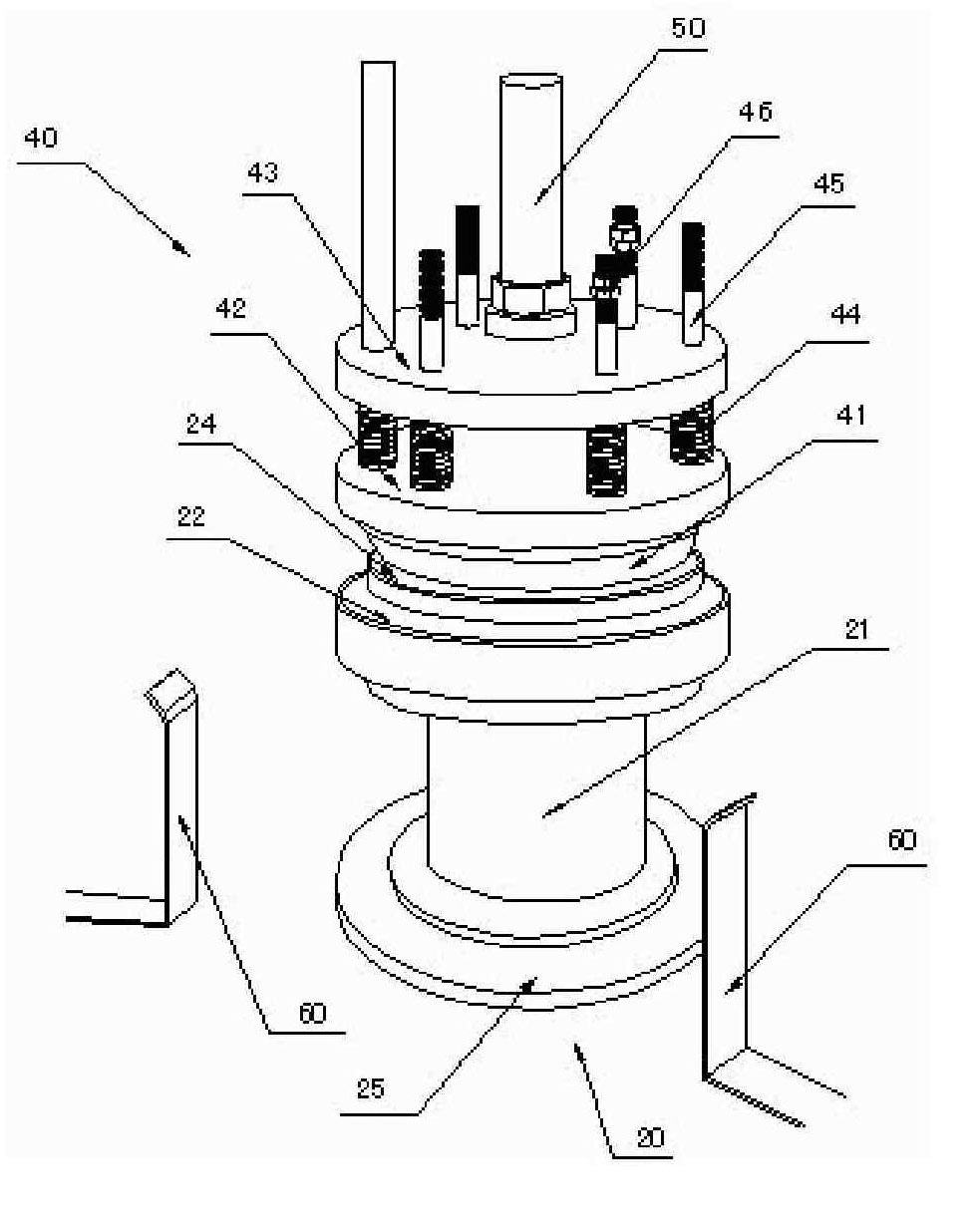

The invention discloses a brazing machine for electric heating composite pan bottom, comprising a brazing machine frame and a welding platform on the frame; a working frame on the welding platform is connected with a pressing rod by a cylinder, wherein the pressing rod can move upwards and downwards; the lower end of the pressing rod is connected with a pressing plate device; the frame (10) is internally provided with a middle frequency induction heating power control device (30); a supporting base (20) is correspondingly arranged between the working frame (13) below the welding platform and the pressing plate device (40); the upper end of the supporting base is provided with a middle frequency heating head (22); a heating process plate (24) is connected above the middle frequency heatinghead; a heating pipe (23) is embedded in the middle frequency heating head; the heating pipe is an internally hollow structure; and the internal chamber of the hollow structure is connected with a water path cooling device. The middle frequency induction heating power supply and an internal heat type brazing are used to heat the internal layer of the composite bottom directly, thus ensuring the uniformity of the brazing temperature at the composite bottom and improving the brazing quality of the composite bottom of the cookers such as composite pot, etc.

Description

Brazing machine for electric heating composite pot bottom technical field The invention relates to a pressure brazing device for heating composite metal materials, in particular to a brazing machine for electrically heating composite pot bottoms. Background technique With the upgrading of the use of modern home kitchens, the convenience and energy saving of home kitchen cooking utensils are also being updated and upgraded. "Induction cooker" products have also become modern as the number of households using electricity instead of gas has increased. Indispensable components for cooking utensils in the family, especially in the case of rising gas energy prices, it is an established trend to use electricity instead of fuel to use cooking utensils. At present, the most suitable frying pans produced in China for "induction cooker" are processed by high-frequency induction heating brazing machine, that is, the double bottom of the stainless steel pot adopts the structure of stai...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): H05B6/06B23K3/08B23K3/047B23K1/002

Inventor 王新田

Owner 王新田

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com