Device and method for comprehensively controlling and protecting pump set of diesel engine

A comprehensive control and protection device technology, applied in computer control, program control, machine/engine, etc., can solve various faults and alarms that cannot be accurately and timely judged, cannot be accurately controlled by diesel engine water pump units, cannot read parameters, Code and other issues, to achieve the effect of simple structure, high degree of automation, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

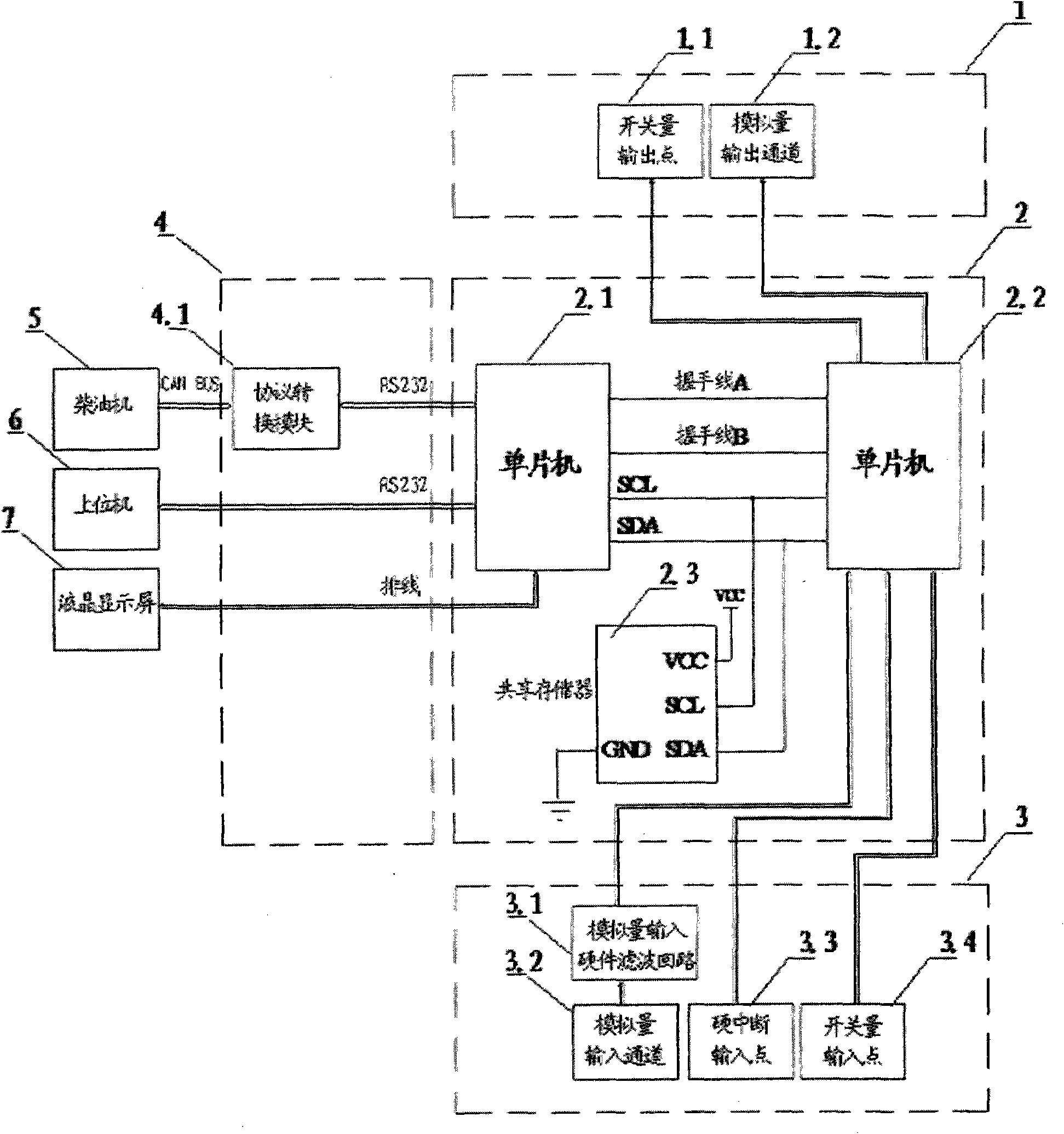

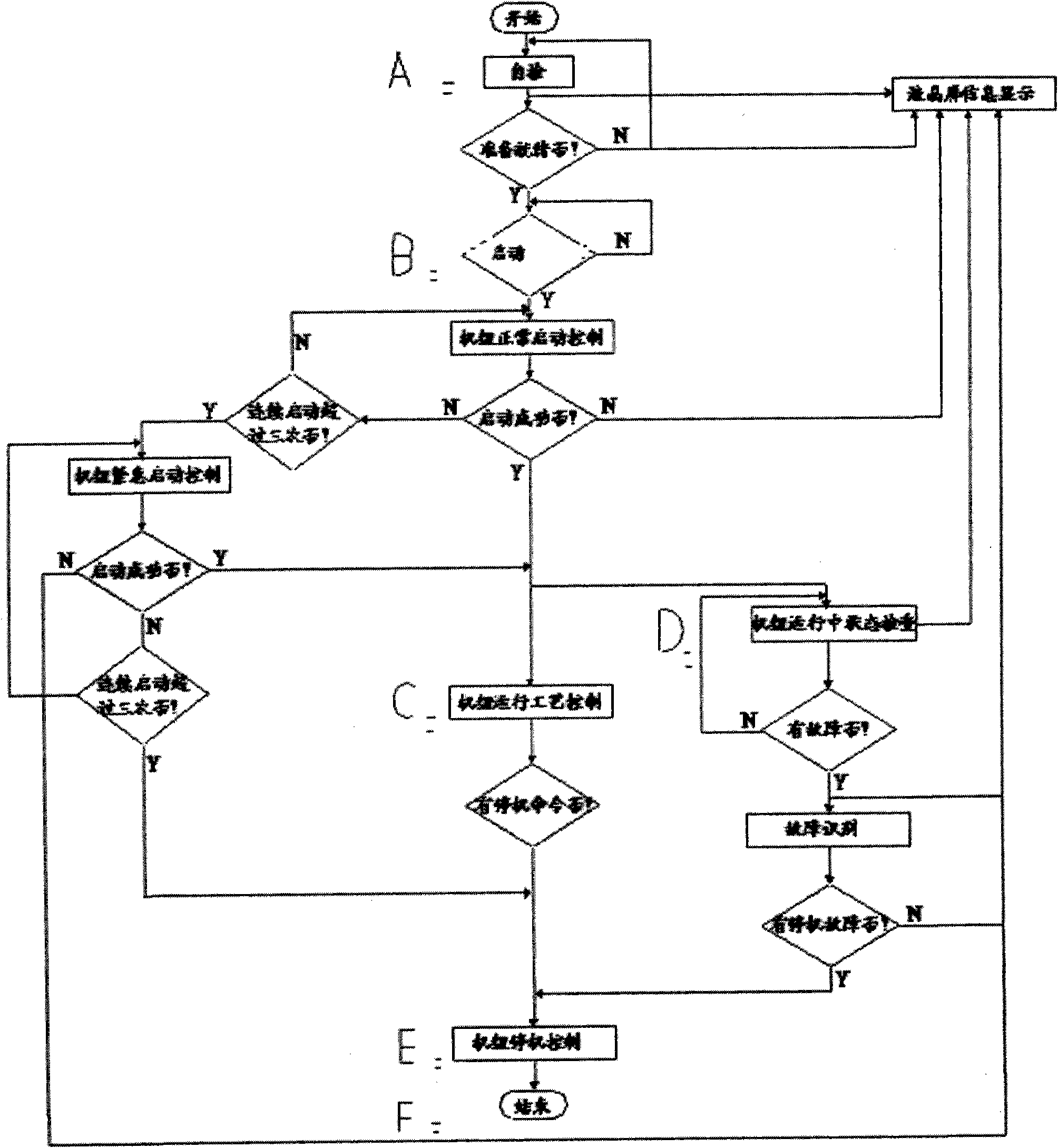

[0039] as attached figure 1Shown: a comprehensive control and protection device for a diesel engine water pump unit, which has a core computing unit 2, a signal output unit 1, a signal input and processing unit 3, and a communication protocol conversion unit 4, the above hardware circuit except the communication protocol conversion unit 4 In addition, they are all integrated on a PCB board, and the PCB board is packaged with a metal case; the core computing unit 2 has a double single-chip microcomputer structure: one of them is the first single-chip microcomputer 2.1, and the other is the second single-chip microcomputer 2.2, the core The computing unit 2 also has a shared memory 2.3; the first single-chip microcomputer 2.1 is connected with the self-contained controller of the diesel engine 5 through a protocol conversion module 4.1, and is used to read the operating state parameters of the diesel engine, and fetch the operating state parameters of the diesel engine to the int...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com