Self assembled ultramicro fan

An assembled, ultra-micro technology, applied in the field of fans, can solve the problems such as the inability to effectively increase the inclination angle and the limited bonding area of the flexible contact 93, so as to achieve the effect of increasing the wind-dispelling effect and improving the quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

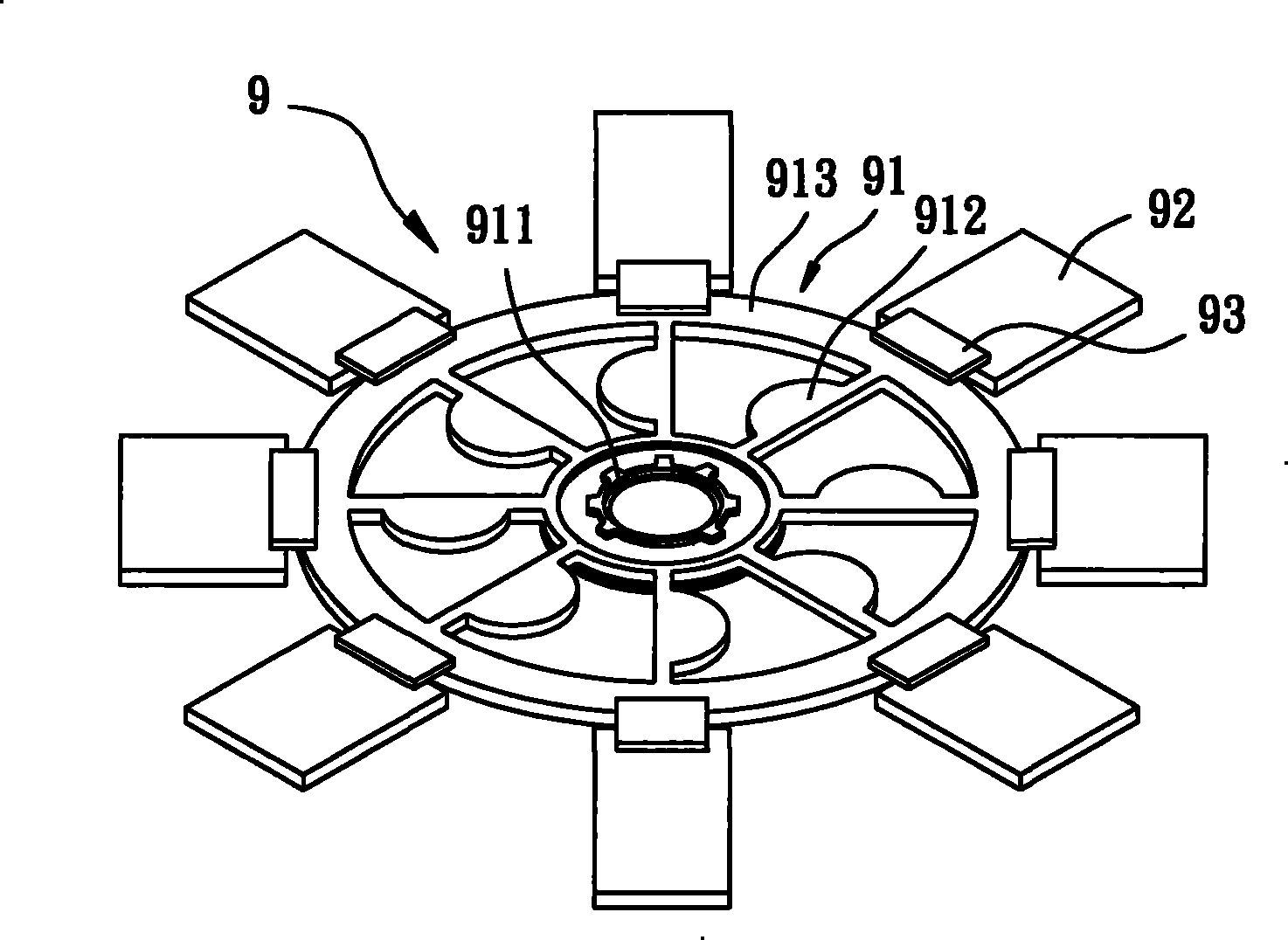

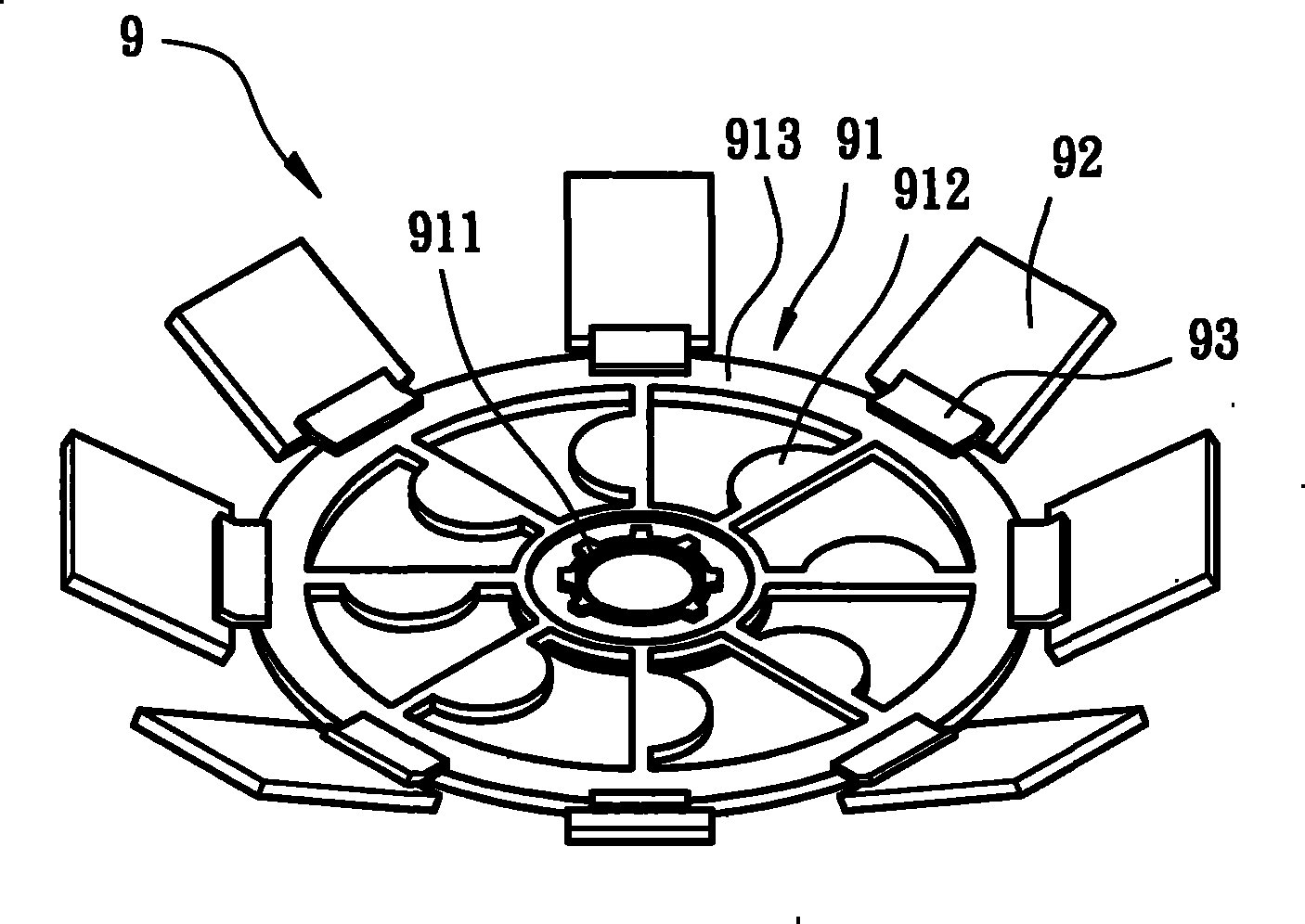

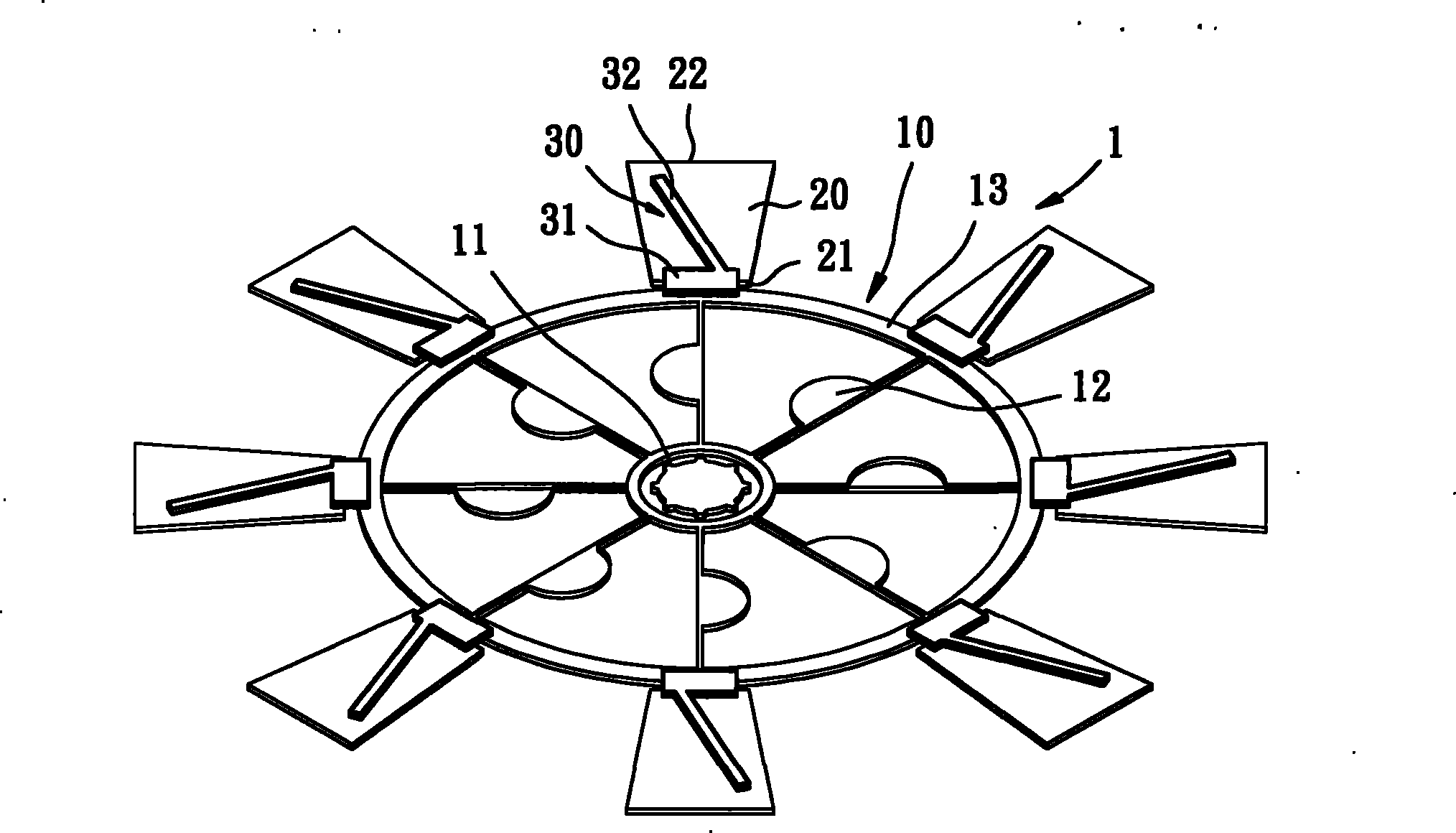

[0050] please refer again image 3 Shown is the self-assembled ultra-micro fan 1 according to the first embodiment of the present invention. The ultra-micro fan 1 includes a body 10 , several blades 20 and several flexible connectors 30 . Wherein the body 10 has a hub 11, the hub 11 is connected to an outer ring 13 with several micro-actuators 12, whereby each of the micro-actuators 12 can be connected between the hub 11 and the outer ring 13, And each of the micro-actuators 12 also has a predetermined distance between each other; each of the blades 20 has a first end 21 and a second end 22, and each of the blades 20 is preferably arranged radially on the body 10 The periphery of the outer ring 13 , the first end 21 of each blade 20 faces the outer ring 13 , and there is a predetermined distance between the first end 21 of each blade 20 and the outer ring 13 .

[0051] The flexible connecting member 30 is selected from a polymer material that can shrink and warp after being h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com