Oxygen-enriched tiny-oil ignition combustion-stabilizing device

A stable combustion device, micro-oil ignition technology, applied in the direction of combustion ignition, ignition by guiding the flame, combustion method, etc., can solve the problems of unsatisfactory fuel saving effect, complicated use and maintenance, coal slagging and blockage, etc. The effect of wide adaptability, simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

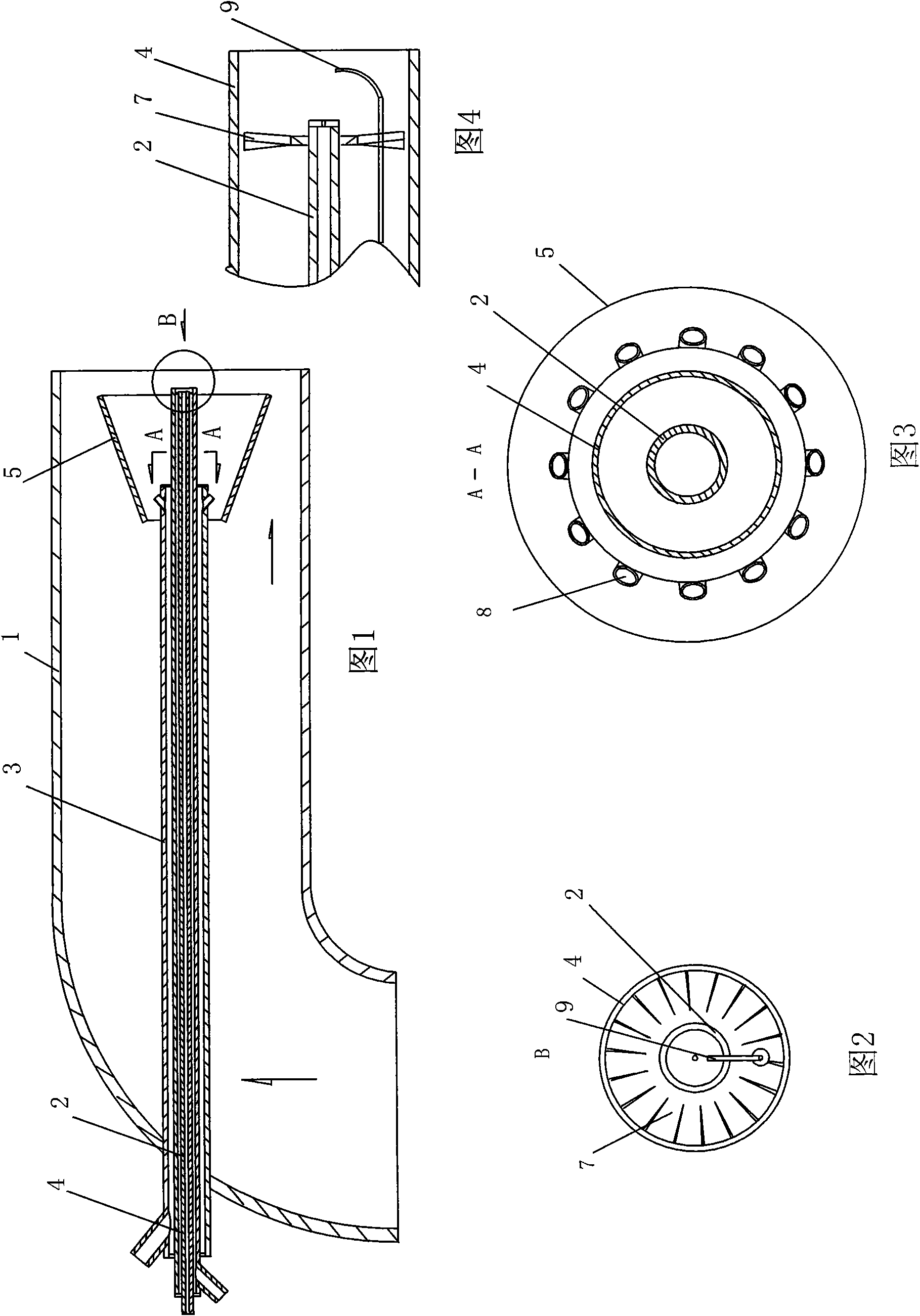

[0019] The oxygen-enriched micro-oil ignition and stable combustion device of the present invention will be further described below in conjunction with the accompanying drawings.

[0020] see Figure 1-Figure 4 , the oxygen-enriched micro-oil ignition and stable combustion device of the present invention includes an ignition fuel conduit 2 with an open right end, and an ignition fuel oxygen conduit 4 coaxial with the ignition fuel oxygen conduit 4 is set at a certain distance outside the ignition fuel conduit 2, and a certain distance is placed outside the ignition fuel oxygen conduit 4 There is a pulverized coal oxygen conduit 3 coaxial with it, and a pulverized coal and oxygen premixing chamber 5 is arranged on the outside of the pulverized coal oxygen conduit 3. The pulverized coal and oxygen premixing chamber 5 is a cone with a small inlet on the left and a large outlet on the right , the right end of the pulverized coal oxygen conduit 3 is located at the left inlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com