Energy tower heat pump unit secondary refrigerant freezing point monitoring control method and device thereof

A heat pump unit, monitoring and control technology, applied in computer control, program control, general control system, etc., can solve the problems such as inability to detect and monitor the freezing point of the refrigerant online, inability to automatically adjust and use unchanged, and heavy maintenance workload, etc. Achieve the effect of improving product competitiveness, reducing operating costs and maintenance costs, and facilitating debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Embodiment 1, using the monitoring control device for the freezing point of the brine of the energy tower heat pump unit, the brine solution concentration and pH value detection device 5 detects the brine solution concentration, temperature, and pH value on-line when the heat pump unit is running. The controller 6 of the heat pump unit transmits various detection signals; the controller 6 performs judgment and analysis according to the received detection signals of the concentration, temperature, and pH value of the brine solution, and looks up the concentration signal to obtain the freezing point temperature of the brine, which is compared with Measure the temperature signal for comparison. If the difference between the freezing point temperature and the measured temperature is less than the set value, a dosing signal will be sent to the brine regulating device of the energy tower to increase the concentration of the brine and reduce the freezing point temperature; if t...

Embodiment 2

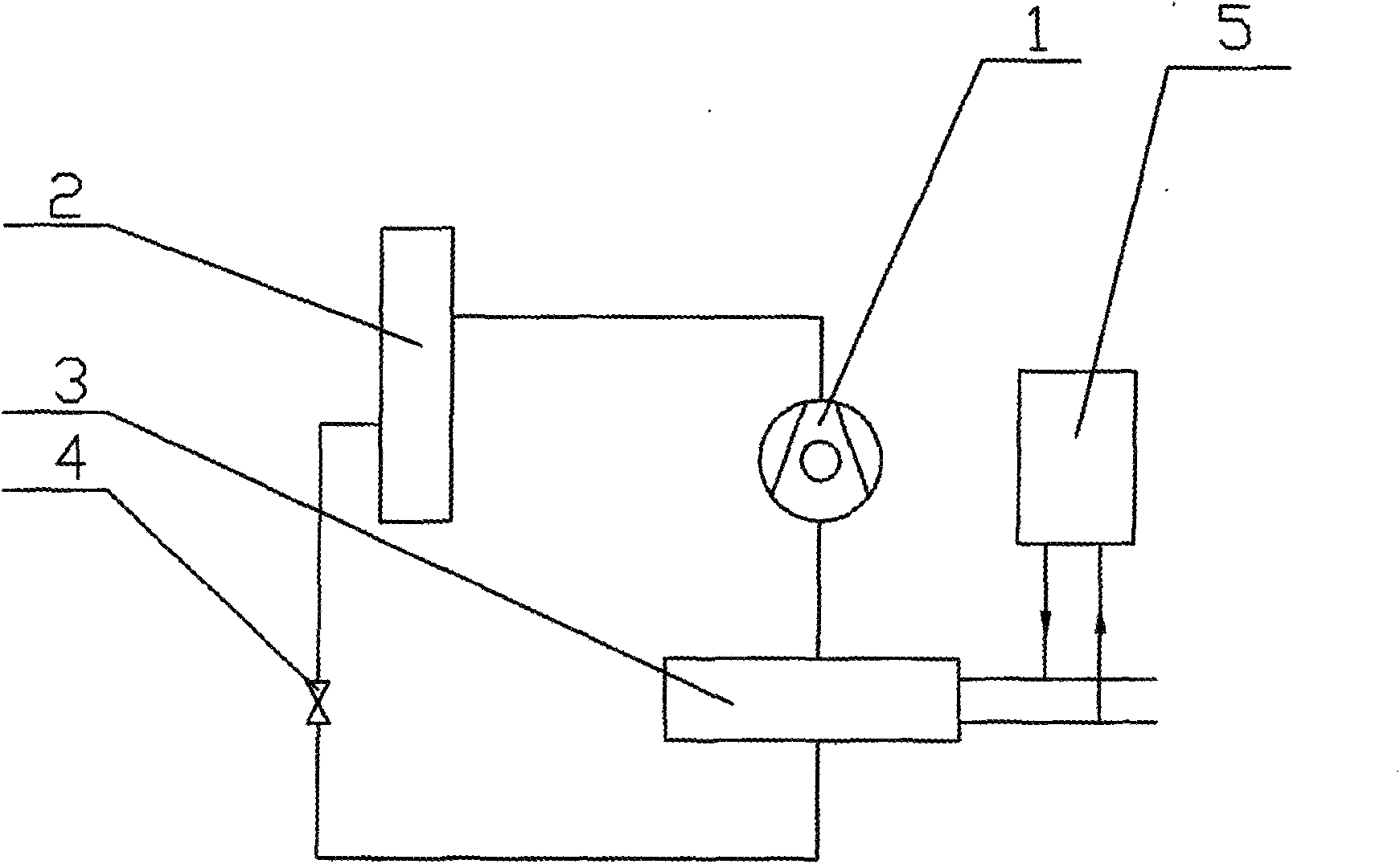

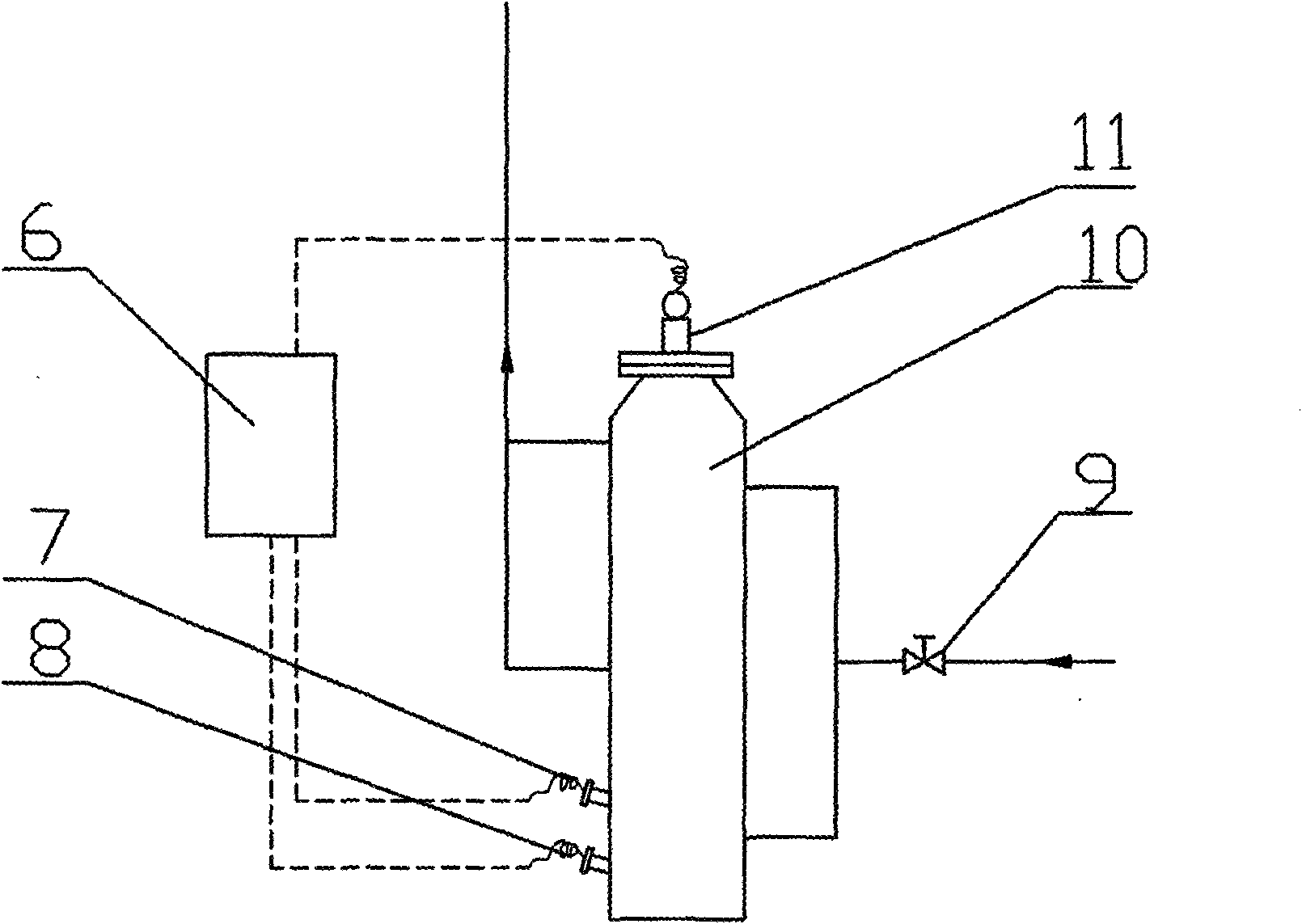

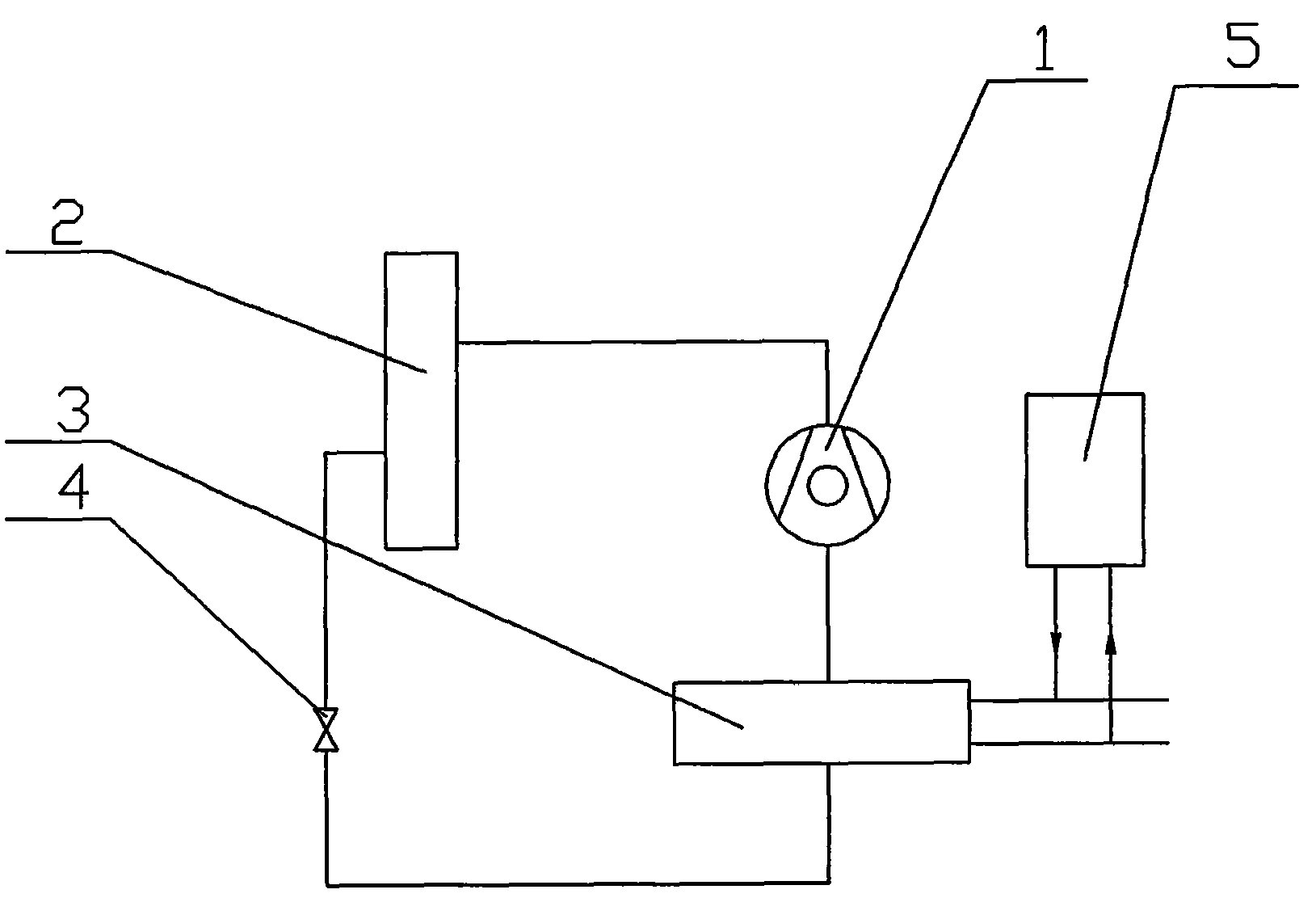

[0018] Example 2, see figure 1 , 2. Realize the monitoring and control device for the freezing point of the bridging refrigerant of the energy tower heat pump unit in Embodiment 1, and connect the compressor 1, the condenser 2, the electronic expansion valve 4 of the energy tower heat pump unit and the evaporator 3 of the energy tower heat pump unit to form a closed In the circuit, the concentration of the refrigerant solution and the pH value detection device 5 are connected on both sides of the water inlet and outlet of the evaporator 3 of the energy tower heat pump unit, that is, the concentration of the refrigerant solution and the pH value detection device are connected in parallel on the water inlet and outlet of the evaporator 3 of the energy tower heat pump unit 5. The brine solution concentration and pH value detection device 5 includes a closed detection barrel 10, and a density meter 11, a pH value meter 7 and a temperature sensor 8 are installed at any position of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com